USGS Mineral Resources Program

The Rare-Earth Elements—

Vital to Modern Technologies and Lifestyles

Until recently, the rare-earth elements (REEs) were familiar to a relatively

small number of people, such as chemists, geologists, specialized materials

scientists, and engineers. In the 21st century, the REEs have gained visibility

through many media outlets because (1) the public has recognized the critical,

specialized properties that REEs contribute to modern technology, as well as

(2) China’s dominance in production and supply of the REEs and (3) inter-

national dependence on China for the majority of the world’s REE supply.

Since the late 1990s, China has provided 85 – 95 percent of the world’s

REEs. In 2010, China announced their intention to reduce REE exports. During

this timeframe, REE use increased substantially. REEs are used as components

in high technology devices, including smart phones, digital cameras, computer

hard disks, uorescent and light-emitting-diode (LED) lights, at screen

televisions, computer monitors, and electronic displays. Large quantities of

some REEs are used in clean energy and defense technologies. Because of

the many important uses of REEs, nations dependent on new technologies,

such as Japan, the United States, and members of the European Union, reacted

with great concern to China’s intent to reduce its REE exports. Consequently,

exploration activities intent on discovering economic deposits of REEs and

bringing them into production have increased.

What are the Rare-Earth Elements?

The REE group is composed of 15 elements that range in atomic number

from 57 (lanthanum) to 71 (lutetium) on the periodic table of elements, and are

ofcially referred to as the “lanthanoids,” although they are commonly referred

to as the “lanthanides.” The rare-earth element promethium (atomic number 61)

is not included in discussions of REE deposits because the element is rare and

unstable in nature. Yttrium (atomic number 39) is commonly regarded as an

REE because of its chemical and physical similarities and afnities with the

lanthanoids, and yttrium typically occurs in the same deposits as REEs. Scandium

(atomic number 21) is chemically similar to, and thus sometimes included with, the

REEs, but it does not occur in economic concentrations in the same geological

settings as the lanthanoids and yttrium and will not be discussed further.

Traditionally, the REEs are divided into two groups on the basis of atomic

weight: (1) the light REEs are lanthanum through gadolinium (atomic numbers

57 through 64); and (2) the heavy REEs comprise terbium through lutetium

(atomic numbers 65 through 71). [Note: Some authorities include europium and

gadolinium within the group of heavy REEs.] Yttrium, although light (atomic

number 39), is included with the heavy REE group because of its similar

chemical and physical properties.

Most REEs are not as rare as the group’s name suggests. They were named

“rare-earth elements” because most were identied during the 18th and 19th

centuries as “earths” (originally dened as materials that could not be changed

further by heat) and in comparison to other “earths,” such as lime or magnesia,

they were relatively rare. Cerium is the most abundant REE, and is more common

in the Earth’s crust than copper or lead. All of the REEs, except promethium,

are more abundant on average in the Earth’s crust than silver, gold, or platinum.

However, concentrated and economically minable deposits of REEs are unusual.

As part of a broad mission to conduct research

and provide information on nonfuel mineral

resources, the U.S. Geological Survey (USGS)

supports science to understand the following:

• Where and how concentrations of rare-

earth elements form in the Earth’s crust;

• Where undiscovered/undeveloped resources

of rare-earth elements may occur;

• Trends in the supply and demand of

rare-earth elements domestically and

internationally;

• How undisturbed and mined rare-earth

deposits interact with the environment.

List of the rare-earth elements found in natural

deposits—the “lanthanides” plus yttrium.

[Average abundance (concentration) in the earth’s crust

(in parts per million) from Lide (2004, CRC handbook

of physics and chemistry, 85th edition). For comparison,

average crustal abundances for gold, silver, lead, and

copper are 0.004, 0.075, 14, and 60 parts per million,

respectively]

Element Symbol

Atomic

number

Crustal

abundance

Light REEs

Lanthanum La 57 39

Cerium Ce 58 66.5

Praseodymium Pr 59 9.2

Neodymium Nd 60 41.5

Samarium Sm 62 7.05

Europium Eu 63 2.0

Gadolinium Gd 64 6.2

Heavy REEs

Terbium Tb 65 1.2

Dysprosium Dy 66 5.2

Holmium Ho 67 1.3

Erbium Er 68 3.5

Thulium Tm 69 0.52

Ytterbium Yb 70 3.2

Lutetium Lu 71 0.8

Yttrium Y 39 33

U.S. Department of the Interior

U.S. Geological Survey

Fact Sheet 2014 –3078

November 2014

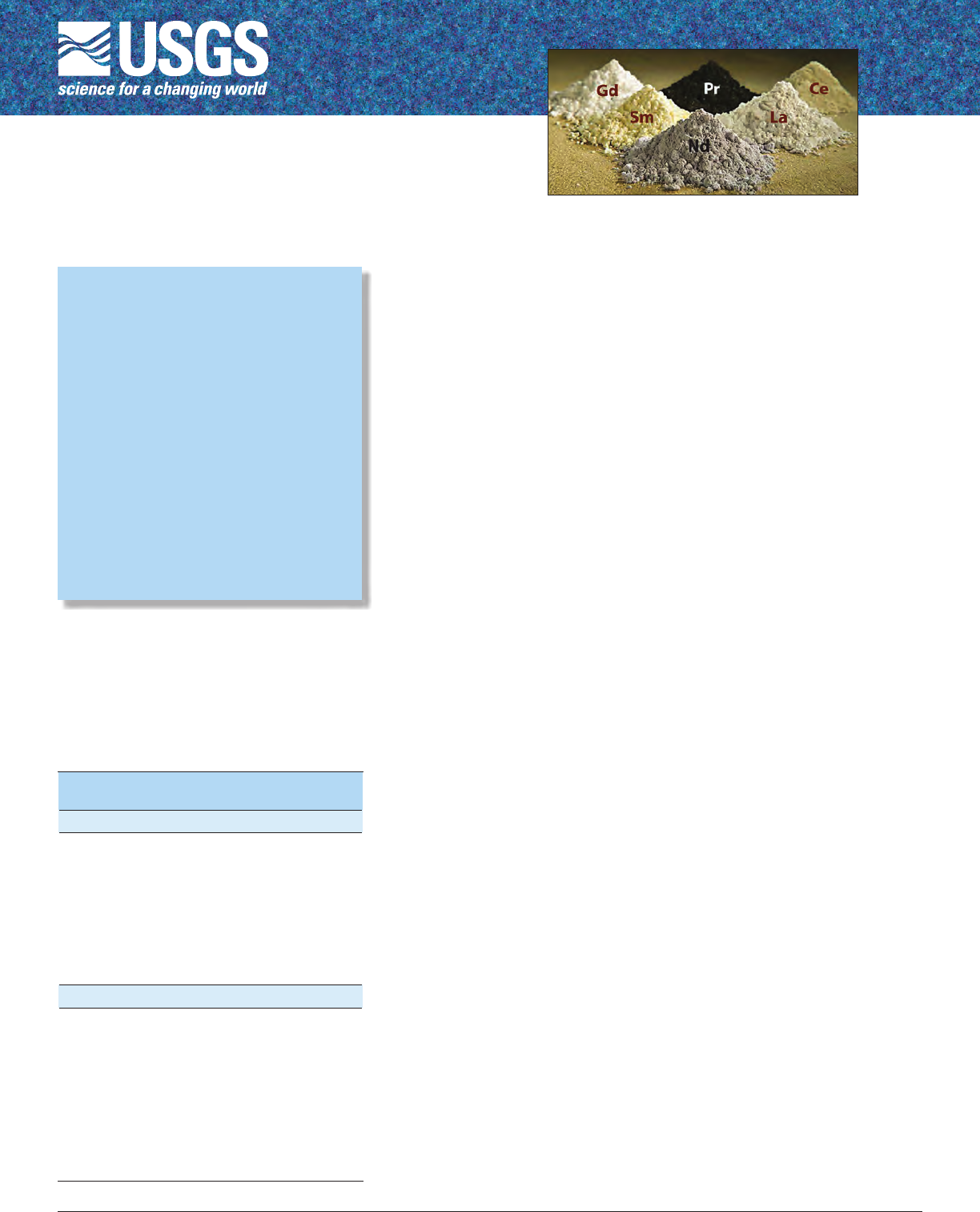

How Do We Use the Rare-Earth Elements?

Due to their unusual physical and chemical properties,

such as unique magnetic and optical properties, REEs have

diverse applications that touch many aspects of modern life and

culture. Specic REEs are used individually or in combination

to make phosphors—substances that emit luminescence—for

many types of ray tubes and at panel displays, in screens that

range in size from smart phone displays to stadium scoreboards.

Some REEs are used in uorescent and LED lighting. Yttrium,

europium, and terbium phosphors are the red-green-blue

phosphors used in many light bulbs, panels, and televisions.

The glass industry is the largest consumer of REE raw

materials, using them for glass polishing and as additives that

provide color and special optical properties. Lanthanum makes

up as much as 50 percent of digital camera lenses, including

cell phone cameras.

Lanthanum-based catalysts are used to rene petroleum.

Cerium-based catalysts are used in automotive catalytic converters.

Magnets that employ REEs are rapidly growing in

application. Neodymium-iron-boron magnets are the strongest

magnets known, useful when space and weight are limiting

factors. Rare-earth magnets are used in computer hard disks and

CD–ROM and DVD disk drives. The spindle of a disk drive

attains high stability in its spinning motion when driven by a

rare-earth magnet. These magnets are also used in a variety of

conventional automotive subsystems, such as power steering,

electric windows, power seats, and audio speakers.

Nickel-metal hydride batteries are built with lanthanum-

based alloys as anodes. These battery types, when used in

hybrid electric cars, contain signicant amounts of lanthanum,

requiring as much as 10 to 15 kilograms per electric vehicle.

Cerium, lanthanum, neodymium, and praseodymium,

commonly in the form of a mixed oxide known as mischmetal,

are used in steel making to remove impurities and in the

production of special alloys.

The end use applications of REEs are detailed in USGS

Scientic Investigations Report 2011–5094 (available at

http://pubs.usgs.gov/sir/2011/5094/).

Rare-earth elements (REEs) are used in the components of many devices used daily in our modern society, such as: the screens of smart phones,

computers, and flat panel televisions; the motors of computer drives; batteries of hybrid and electric cars; and new generation light bulbs.

Lanthanum-based catalysts are employed in petroleum refining. Large wind turbines use generators that contain strong permanent magnets

composed of neodymium-iron-boron. Photographs used with permission from PHOTOS.com.

Did you know....

Rare-earth magnets are stronger per unit weight

and volume than any other magnet type. Clean energy

technologies, such as large wind turbines and electric

vehicles, use rare-earth permanent magnets (meaning

permanently magnetized) that usually contain four REEs:

praseodymium, neodymium, samarium, and dysprosium.

Where Do Rare-Earth Elements Come From?

The REEs are commonly found together in the Earth’s

crust because they share a trivalent charge (

+3

) and similar ionic

radii. In nature, REEs do not exist individually, like gold or

copper often do, but instead occur in minerals as either minor

or major constit uents. In general, these minerals tend to be

dominated by either light or heavy REEs, although each can

be present. In igneous (magmatic) systems, the large sizes of

the REE ions impede their ability to t into the structure of

common rock-forming minerals. As a result, when common

silicate minerals crystallize — such as feldspars, pyroxenes,

olivine, and amphiboles— most REEs tend to remain in the

coexisting magma. Successive generations of this process

increase REE concentrations in the residual magma until

individual REE minerals crystalize. The REEs can substitute for

one another in crystal structures, and multiple REEs typically

occur within a single mineral.

REEs generally occur in uncommon geologic rock types

and settings. As mentioned earlier, REEs are common in the

Earth’s crust but rarely in economic concentrations. Economic

REE deposits occur primarily in four geologic environments:

carbonatites, alkaline igneous systems, ion-absorption clay

deposits, and monazite-xenotime-bearing placer deposits. Even

within these deposit types, minable (economic) concentrations

of REEs are rare. For example, globally there are more than

500 known carbonatites but only 6 are currently mined for REEs.

Other deposit types can contain minor amounts of REEs

but have not been important REE sources thus far. One example

is the giant Olympic Dam iron oxide-copper-uranium-gold-

silver deposit in Australia, the world’s largest single uranium

deposit, which also contains REE enrichments. So far it has not

proven economical to recover REEs from this deposit.

Carbonatites host the world’s largest REE deposits and

are typically most enriched in the light REEs. Carbonatites are

unusual igneous rocks derived from carbonate-rich magmas, in

contrast to the more common silica-rich magmas. Carbonatites

are igneous rocks with more than 50 percent carbonate minerals,

usually calcite and dolomite. As a group, carbonatites have the

highest REE concentrations of all igneous rocks. Carbonatites

have been the world’s main source for light REEs since the

1960s. Currently, REEs are mined from large carbonatite

bodies in California (Mountain Pass) and in China (Bayan

Obo, Maoniuping, Daluxiang, and Weishan). The Mount Weld

mine in Western Australia, Australia, produces REEs from a

weathered zone that overlies a carbonatite.

Alkaline igneous rocks comprise a group of uncommon

igneous rock types generally decient in silica, relative to

sodium, potassium, and calcium. Many current (2014) advanced

exploration projects are focused on large bodies of alkaline

igneous rocks, with some nding signicant REE concen trations

(0.3 –2.6 percent total REE oxide). These deposit types are sought

because they are often enriched in the important heavy REEs.

Ion-adsorption clay deposits in southern China are the

world’s primary source of heavy REEs. This deposit type is

informally referred to as “south China clays.” Thick clay accu-

mulations that host low concentrations of REEs (from about

0.04 to 0.25 percent total REE oxides) form in tropical regions

with moderate to high rainfall through successive processes:

1. REEs are leached by groundwater from granite bedrock;

2. thick zones of clay-rich soils develop above the granites; and

3. mobilized REEs become weakly xed (by ion-adsorption)

onto clays in the soils.

Despite their low concentrations in REEs, the clay deposits

of south China are economic because the REEs can be easily

extracted from the clays with weak acids, the deposits are often

enriched in high-value heavy REEs, and labor costs are low.

A pilot project in Jamaica is evaluating the recovery

of REEs from tailings of red mud produced by bauxite

(aluminum ore) mining, which could be considered a form

of ion-adsorption clay deposit.

Monazite-xenotime-bearing placer deposits were impor-

tant REE sources prior to the mid-1960s. From some modern

and ancient beach deposits, the REE-thorium-phosphate mineral

monazite [(REEs,Th)PO

4

)] can be recovered as a by-product

during the extraction of the targeted heavy minerals, ilmenite

(FeTiO

3

), rutile (TiO

2

), and zircon (ZrSiO

4

). Ilmenite and

rutile —the principal minerals of value as in these deposits—are

mechanically separated from sand-silt deposits. Monazite can

be recovered simultaneously if desired. The separated ilmenite

and rutile are then chemically processed to remove titanium;

ilmenite and rutile are the primary source of the titanium used

in paint pigments. Monazite is recovered as a byproduct mineral

from beach sands along the southern coasts of India, where it

is sought as a source of light REEs and thorium. The recovered

thorium is stockpiled for future use as fuel material in thorium-

based nuclear power, which is under development. Xenotime

(YPO

4

), a less common mineral, has been recovered as a source

of yttrium and other REEs as a byproduct of mining tin placers.

The mineral monazite is an important source of the REEs.

Monazite, a REE-thorium-phosphate mineral, has been

separated from some ancient and modern beach sands

as a coproduct to the recovery of economic titanium (Ti)

minerals. Photograph courtesy of www.geology.com.

The mineral bastnäsite is

an important source of the

REEs. Bastnäsite, a REE-

carbonate-fluorine mineral,

is the primary ore mineral

in the world’s largest REE

deposits. Photograph

courtesy of Rob Lavinsky,

www.iRocks.com.

Worldwide Supply and Demand for Rare-Earth Elements

As noted earlier, in recent years Chinese production has accounted for

about 95 percent of the REE global market. Citing a need to retain their limited

REE resources for domestic requirements and concerns for environmental effects

of mining, China has restricted the supply of REEs through quotas, licenses, and

taxes. As a result, the REE industry outside of China increased REE stockpiling,

explored for deposits in many locations, and promoted new efforts to conserve,

recycle, and nd substitutes for REEs. New mine production has begun in

Australia (Mount Weld) and the United States (Mountain Pass, California).

In recent years, expert panels convened by research institutes and

government agencies highlighted specic REEs as raw materials critical to

evolving technologies, such as clean-energy applications, high-tech military

components, and electronics (Long and others, 2010). These reports suggest

that a high potential exists for disruptions in REE supplies. As a result,

several expert panel analyses rank REEs high on the “criticality” factor of

raw materials, meaning they are of high technological and economic impor-

tance and have high supply-side risk (National Research Council, 2008). Panels and agencies that assessed the criticality of REEs and

other raw materials include the National Research Council, U.S. Department of Energy, European Commission, American Physical

Society (APS) and Materials Research Society (MRS), and the Resnick Institute.

Worldwide explorations for economic deposits of REEs and efforts to bring them into production have increased substantially

since 2000. More than 400 rare-earth projects were in progress during 2012, including many projects in advanced stages of explora-

tion, meaning that the deposit sizes and REE concentrations were announced based on detailed drilling. One important aspect in the

development of a property for REE mining is the cost and complexity of processing the REE ores. Recovery of REEs can be complex

because they occur in minerals as a group of similar elements, and at many deposits the REEs are hosted within more than one

mineral. Not only do REE-rich minerals need to be concentrated, but the actual elements must be separated from each other, usually

as oxide compounds (for example, lanthanum oxide). The success and timeliness of rare-earth mining projects, and the rare-earth

elements industry in general, is difcult to predict and will be continuously monitored and studied by the USGS.

References

Lide, D.R., ed., 2004, Abundance of elements in the Earth’s crust and

in the sea, in sec. 14 of CRC handbook of physics and chemistry—

A ready-reference book of chemical and physical data (85th edition):

Boca Raton, Fla., CRC Press, p. 17 [table].

Long, K.R., Van Gosen, B.S., Foley, N.K., and Cordier, Daniel,

2010, The principal rare earth elements deposits of the United

States—A summary of domestic deposits and a global perspective:

U.S. Geological Survey Scientic Investigations Report 2010 –5220,

96 p. [Also available at http://pubs.usgs.gov/sir/2010/5220/.]

National Research Council, 2008, Minerals, critical minerals, and the

U.S. economy: Washington, D.C., National Academies Press, 264 p.

[Also available at http://www.nap.edu/openbook.php?record_id=12034.]

For More Information

On production and consumption of rare-earth elements:

http://minerals.usgs.gov/minerals/pubs/commodity/rare_earths/

On historical statistics of rare-earth elements:

http://minerals.usgs.gov/ds/2005/140/

On end use and recycling of rare-earth elements:

http://pubs.usgs.gov/sir/2011/5094/

The USGS Mineral Resources Program is the sole Federal provider

of research and information on rare-earth elements and other nonfuel

mineral resources. For more information, please contact:

Mineral Resources

Program Coordinator Telephone: 703-648-6100

U.S. Geological Survey Fax: 703-648-6057

913 National Center E-mail: [email protected]

Reston, VA 20192 Home page: http://minerals.usgs.gov

Text prepared by Bradley S. Van Gosen, Philip L. Verplanck,

Keith R. Long, Joseph Gambogi, and Robert R. Seal II.

The Mountain Pass mine of Molycorp, Inc., southeastern

California, is the only active producer of REEs in the United

States (2014). The ore body is a carbonatite intrusion,

thought to be the largest REE resource in the United States.

How Do We Ensure Adequate Supplies of

Rare-Earth Elements for the Future?

Global REE resources are estimated to be 110 million

metric tons of rare-earth oxide, which primarily occur, in

descending order, in China, Russia, the United States, India, and

Australia. Exploration for additional REE deposits is ongoing;

therefore, the world’s known in-the-ground resources (endow-

ment) of REEs are likely to increase. Despite many known REE

deposits, the global supply of REEs is limited by the cost and

complexity of exploring REE deposits and developing REE

mines, including REE extraction and separation facilities. These

factors are discussed in USGS Scientic Investigations Report

2010 –5220 (available at http://pubs.usgs.gov/sir/2010/5220/).

In addition to bringing more REE deposits into produc-

tion, other methods may help offset REE supply restrictions.

Examples include new efforts to recycle REEs, research to nd

substitute materials for REEs, and efforts to recover REEs as

coproducts of mineral deposits. These efforts may eventually

offset some of the demand for REEs.

ISSN 2327– 6932 (online)

http://dx.doi.org/10.3133/fs20143078

Did you know....

In the 1940s, as part of the Manhattan Project that

created the nuclear bomb, Frank Spedding and others in the

United States developed chemical ion exchange procedures

that could separate and purify individual REEs. This method

was first used to separate plutonium-239 and neptunium

from uranium, thorium, and actinium in materials generated

by nuclear reactors.