The Value of an EHS Management of Change

Process

Richard Hirsh, MPH CIH FAIHA

Director, EH&S

Nektar Therapeutics

December 6

th

, 2017, CIHC Professional Development Conference, San Francisco, CA

The Value of an EHS Management of

Change Process

DISCLAIMER

This presentation contains opinions and perspectives from various

EHS Professionals on the topic entitled: “The Value of an EHS

Management of Change Process”.

This presentation does not necessarily represent the opinion of the

presenter nor “Nektar Therapeutics,” nor are the practices and

approaches addressed herein warranted or guaranteed to sufficiently

address any or all EHS concerns. This presentation is informational

only; please consult an EHS professional to ensure your particular

circumstances are understood prior to implementing any EHS

program or change.

2

Agenda

MOC Process Rationale, Definitions, Principles

Real Life Scenarios

MOC Types and Workflow

Introducing Chemicals, Processes, Equipment, Personnel

EHS MOC Process Examples

Conducting an EHS Review: 10 Simple Steps

Levels of Change - Examples

Key MOC Processes, Tools, Learnings, Benefits

3

Why Manage Change?

Uncontrolled change is a frequent contributor to

incidents, and can result in injury to personnel,

damage to the environment, and loss of quality.

Managing change is essential to maintaining and

improving the EHS controls of existing operations,

and for the safe startup and operation of a new

process or facility.

4

Management of Change (MOC)

Management of Change (MOC) Process

A system to assess and address the EHS impacts of change

to a process, equipment, facilities, procedure, personnel or

organization, before the changes are made.

Key Principles

• Every change must be managed

• Changes must not be made without an appropriate review

• The type of review should be consistent with the

complexity of the change

• MOC system should be simple to use

5

Scenario - Polymerization Example

July 20, 1988: Tank-car of acid-washed MAA polymerized violently in

Houston rail yard. MAA put in car had low inhibitor. Car was stainless,

not normal lined car for this grade. H

2

SO

4

reacted with car walls.

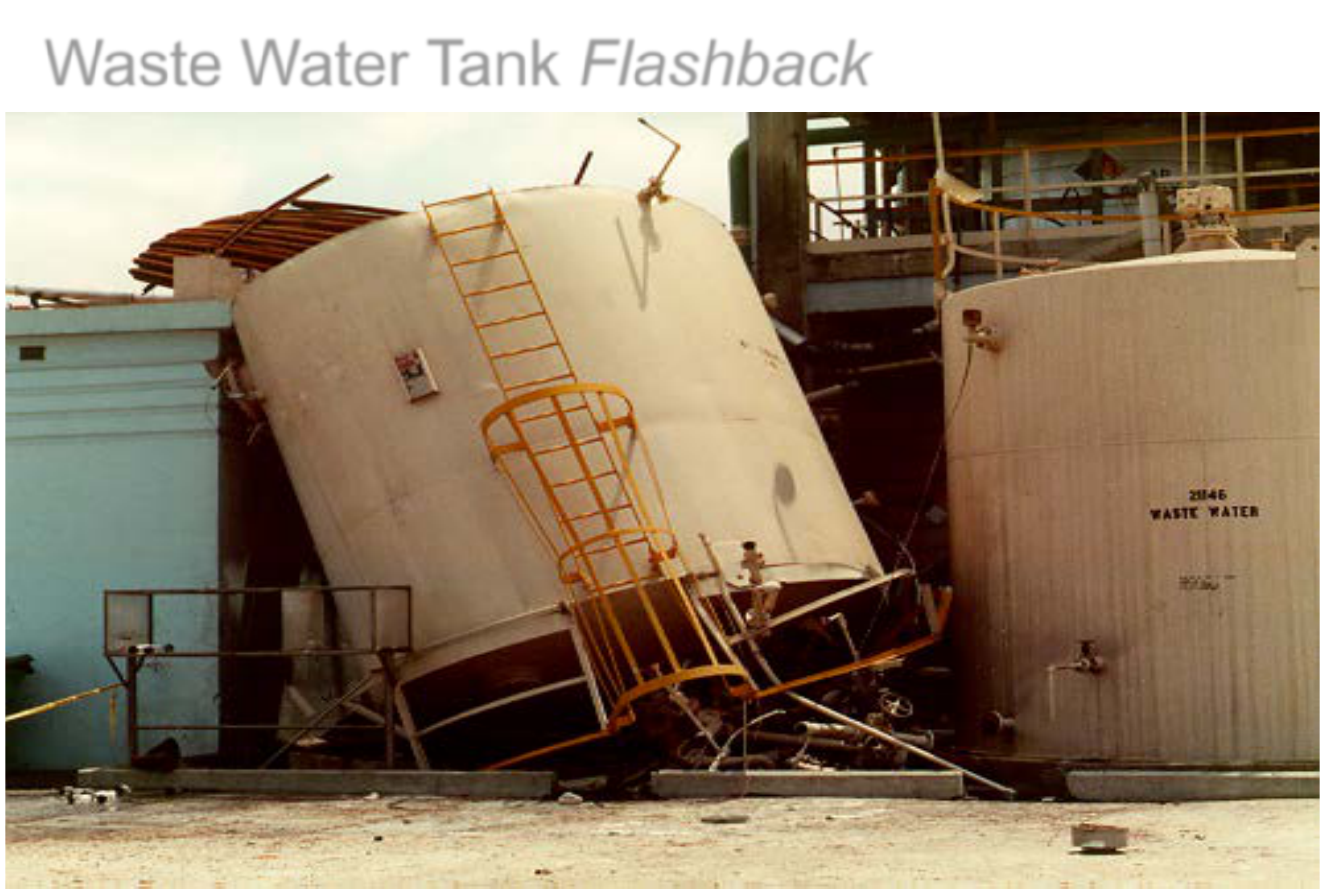

Waste Water Tank Flashback

1988: Organic layer floating on water in tank. Tank draining to sewer

trench. Welding overhead. Tank emptied. Welding spark to trench.

Flashback into tank. Tank launched and turned upside down.

Other Real Life Scenarios

New -80C freezer requires 208V

Ammonia added to 4L DCM bottle

Ventilated enclosure installation

Switched HPLC solvent to DMF

Filtering “non-hazardous” product

Sub-contractor pouring wet cement

Runaway glacial acrylic acid polymerization

Heptane tanktruck explosion

Employee sprayed with hot 3,4-dichloropropionanilide

8

Why EHS inclusion is essential in both the

design and start-up stages?

9

Comply with EHS

Regulations

Mitigate

Environmental

Risks

Mitigate Safety

Risks

Protect Employees

EHS Inclusion in Design

and Start-up Stages

Integrate EHS aspects into

Design. Ensure start-up

addressed all issues.

Complex to retrofit

Live with design

flaws

MOC Types and Workflow

MOC Process needs to address Permanent, Temporary, Emergency Changes

Description, Justification, Impact on EHS

• What, Where, When, Who, and Why?

Initiating Changes:

• Reduce the risk of unintended consequences due to change

• Seek and maintain records of technical and financial input to a change

• Provide visibility to changes being planned or already underway

Approving Changes

• Review the change request to gain an understanding of the proposed change

and its impacts

• Indicate what changes to the initial request are necessary, if any, in order for the

change request to be approved

• Indicate support for proceeding with the proposed change

10

Introducing a New Chemical

Hazardous Material Business Plan updated?

Which work areas/employees will be handling this material?

What other employees might be affected (e.g. maintenance, waste

handlers)

Safety Data Sheet?

New Hazards Presented?

OSHA regulations? Fire Code? OELs? Monitoring method? Exposure

potential?

How will chemical be stored and used?

Training?

Medical surveillance?

Engineering controls? PPE? Respiratory Protection?

Waste Stream?

11

Example: Ordering Chemicals

How does the ordering process work?

New material or used before? Any adverse incidents or

institutional knowledge that needs to be integrated?

What documentation is needed and how do I find it?

How much do I need to order?

Is there sufficient storage space?

Do we have a waste stream designated?

What do I do if there is a spill of this material?

12

Example of how this process work?

13

Requestor

submits PR and

supporting

documentation

EHS checks for

documentation

and EH&S risks

EH&S

approves

material

EH&S asks for

additional info or

provides specific

PPE/Safety

information

Dept.

Manager

approves

material

Purchasing

sources

material and

places order

Supplier

ships

material to

Company

Materials

Mgmt.

receives

material and

contacts

requestor

Requestor

picks up

material at

designated

area

MOC Example: Introducing an Active

Pharmaceutical Ingredient into R&D

Proactive Quarterly Dept Mgr Meetings to anticipate and

prepare for new API introductions

Chemical Review and Approval Process

Occupational Health Categorization (1-4); Default Cat - 3

SOP, Training, Exposure Assessment, Engineering Controls

Sample Shipment triggers SDS development

Phase 2B Clinical Trials triggers OEL/Monitoring and

Analytical Method Development

14

New Processes

Major new installations or process changes

involving hazardous chemicals. Examples: addition

of a new reactor; addition of a new process that

uses a hazardous chemical.

Requires HAZOP and formal EHS reviews in design,

construction and before startup.

15

Introducing a New Process

Batch or continuous process?

Operating pressures/temperatures?

Exothermic reaction steps?

Process flow?

Charging/removing materials from containment?

Open handling vs closed system?

Materials of construction?

Process hazard analysis?

16

Introducing New Equipment

17

Robotic?

Ergonomics?

What materials will be in contact with equipment?

Magnetic fields?

Ionizing or non-ionizing radiation?

Exposed moving parts?

Is noise generated?

Air emissions?

Waste generation?

Access by maintenance staff for repairs, PM?

Introducing New Equipment

18

For New Construction, Renovations and Remodels:

Storage, handling, release of potentially hazardous materials

(chemical, biological, physical hazards)?

Installation/removal of safety showers/eyewashes?

Permit required confined spaces or machine guarding issues?

Impacts on LEV or other control equipment?

Wastewater discharge?

Will project affect Life Safety issues?

• Installation/modification of fire alarm or suppression systems

• Installation of elevators or other lift devices

• Change of egress routes, exit signage

• Access/egress restrictions

Introducing New Personnel

Essential experience, skillsets and training to do the job?

Training curricula/assignments?

Evacuation roster?

Workstation ergonomics evaluation?

Medical surveillance program?

Respirator clearance and use?

Prescription safety glasses?

Clearly defined roles and responsibilities?

19

Example of an MOC Process –

Before Change Happens

• Identify the level of change and type of review needed

• Gather the information needed to identify hazards

• Gather the people needed for the review

• Include additional internal or external experts if

needed

• Conduct the EHS review

• Classify actions by priority

• Assign responsibilities and due dates for actions

• Follow-up on actions

• Document actions to closure

20

Levels of Change - Examples

21

Identical Change

• Same material, same quality, same concentration, same

everything

Like for Like (Replacement in Kind)

• Same material, same quality, same concentration, almost same

everything, exception, ex. different supplier

Basic Change

• Same or different material, same quality, different concentration

outside the scope of the

original review

Major Change

• New or unfamiliar material or equipment where no review has been

conducted

Example of How EHS Reviews Match the

Complexity of Change

22

Type of Review

Identical

Change

Like for Like

(Replacement

In Kind)

Basic

Change

Major Facility

or Process Change

Personal Review

EHS Review, EHS

Professional

optional

Always an EHS Review with

an EHS Professional

present;

May also require a Process

Hazard Analysis*

Level of Change

At this level add

the Specialists:

• Risk Analyst

• Specialists

• Environmental/

Regulatory Expert

•Facilities Engineer

Typical Parties Involved:

• Management of operation

• 2 Persons knowledgeable

of change

• Affected persons (e.g. lab

tech)

• EHS representative

Expertise of the person making the

change

Personal EHS Review - Example

The personal EHS review is used when you are

making an identical substitution. Verify that

nothing is being changed.

Documentation: none required

People involved: the person making the

substitution

23

Simple EHS Review - Example

Documentation: recommended but not required

People involved: the person who knows about the

effects of the change, and the owner of the

equipment. Always have two areas of responsibility

involved.

The simple EHS review is used when you are

making the same general type of substitution,

but not an identical substitution.

24

Formal EHS Review - Example

The formal EHS review is used when you are making a

basic change and when introducing new processes.

Documentation: minutes from the formal EHS meeting and

action points.

People involved:

• Originator of the change,

• Person(s) who will be affected by the change;

• Person who knows about the effects of the change;

• Management representative from the area that is affected;

• EHS representative;

• Person who will maintain the equipment.

25

Formal EHS Review - Example

Designed to identify, evaluate and eliminate potential hazards by

people who understand the hazards and necessary safeguards for

the change

Proposed change meets the criteria for Basic Change or Major

Process or Facility Change

Meeting with department management designee and personnel

responsible for proposed change, affected personnel, EHS

Professional

Documentation is required

• Classify actions by priority

• Assign responsibilities and due dates for actions

• Follow-up on actions

• Document actions to closure

26

PHA/HAZOP Review - Example

The PHA/HAZOP review is used when you are

adding a major new facility or new processes

Documentation: minutes from the PHA/HAZOP

meeting, action points and changes to P&ID’s.

People involved: a PHA/HAZOP expert is the leader,

and the team is made up of site personnel including

those affected by the changes being considered.

27

Major Accident Prevention Plan Study

A MAPP study is performed for process changes

and new processes involving bulk chemical

quantities above the minimum storage

amounts.

Documentation: minutes and action points from

the MAPP study.

People involved: a MAPP expert is the leader, and

the team is made up of site personnel.

28

Example of Conducting an EHS Review:

10 Simple Steps

1. Select a leader. This is usually the person who

initiated or knows the most about the change.

2. Appoint someone to take meeting minutes.

3. Agree on the purpose of the EHS Review.

4. Define scope and explain the proposed change.

5. If appropriate, review flow sheets, plans or other

drawings that shows the change being proposed.

6. If appropriate, visit the location of the change and

review each part of the change.

29

Example of Conducting an EHS Review:

10 Simple Steps

7. People ask questions to understand the change and discuss

the EHS aspects and potential impacts of the change. At

this point, it is useful to use an EHS review checklist.

8. During the review, the person taking notes records action

items.

9. After visiting the location of the change, the people return to

the meeting room. They review the action points and assign

completion dates, priorities and responsibilities for the

action points.

10. A system is used to track action points to closure. The EHS

review is finished when all action items have been closed.

30

EHS Review Summary

31

Type of EHS Review

Identical

Replacement

in Kind

Basic Change

New Process

Personal Review Simple EHS Review

Formal EHS Review

Formal EHS Review

and HAZOP /MAPP

No

documentation

needed

Gather People and

resources

Fill the simple EHS

review form

Gather People and

resources

Conduct the review

Document and update

systems and procedure

Key Management of Change Processes

Chemical Review and Approval Process

• In the Pharma World this would include APIs, Biologics and Chemicals

Capital Requests – EHS Review

• new project/ new equipment ≥$5000

Employee On-boarding/Off-boarding

• Training, ergonomics assessments, facility access/security, risk assessments, medical

surveillance

Workflows and Approvals for New Equipment Design and Start-up

Reviews

Technology Transfer between sites/partners

Emergency Changes – Non-Routine Tasks!

Process Hazard Analyses

32

Key MOC Tools and Learnings

EHS Management of Change SOP

Training on MOC Processes

Proactive Quarterly Dept. Meetings with EHS,

Facilities and Affected Department Managers

Defining Acceptable Process Parameters/Boundaries

beyond which the MOC Process is triggered

Leveraging Software Tools

33

Management of Change Benefits

Involves affected employees - Two heads are better than one

Identifies:

• Hazards before they become incidents

• Problems when they are least expensive to fix

• Safeguards and actions to reduce risk

• Training and procedures that are needed

Reduces risk of:

• Injuries and illnesses

• Environmental spills and releases

• Catastrophic events (e.g. fire / explosion)

Confirms built-as-designed, avoids rework, and verifies EHS

requirements for safe operations

34

Acknowledgments

Paul Snyder, CIH, CSP (retired) – former IH/Safety Director for

Rohm and Haas Company

Robert Bacci, CIH, CSP – VP EHS and Facilities, Nektar

Therapeutics

Ben English, CIH, CSP – Sr. Staff EHS Specialist, Nektar

Therapeutics

Sundar Ramachandran, CIH – Associate Director EHS, Nektar

Therapeutics

35

36