Instruction Manual

ControlNet

Communications Module

M/N RECOMM-CNET

D2-3497

©2001 Rockwell Automation. All rights reserved.

The information in this manual is subject to change without notice.

Throughout this manual, the following notes are used to alert you to safety

considerations:

Important: Identifies information that is critical for successful application and

understanding of the product.

!

ATTENTION:

Identifies information about practices or

circumstances that can lead to personal injury or death, property

damage, or economic loss.

This product has been self-tested by the manufacturer and found to comply with

ControlNet International Conformance Test Software Version 12.

Windows, Windows NT, and Microsoft are trademarks of Microsoft Corporation.

ControlNet is a trademark of ControlNet International, Ltd.

Reliance, SP600, VS Utilities, DPI, RSLogix, ControlLogix, and SLC are

trademarks of Rockwell Automation.

!

ATTENTION:

The drive may contain high voltages that can cause

injury or death. Remove all power from the drive, and then verify

power has been removed before installing or removing a

ControlNet module. Failure to observe these precautions could

result in severe bodily injury or loss of life.

ATTENTION:

Only qualified electrical personnel familiar with

drive and power products and the associated machinery should

plan or implement the installation, start up, configuration, and

subsequent maintenance of the product using a ControlNet

module. Read and understand this manual in its entirety before

proceeding. Failure to observe these precautions could result

bodily injury and/or damage to equipment.

ATTENTION:

DPI host products must not be directly connected

together via RECBL-xxx cables. Unpredictable behavior due to

timing and other internal procedures can result if two or more

devices are connected in this manner. Failure to observe this

precaution could result bodily injury and/or damage to equipment.

ATTENTION:

If the ControlNet module is transmitting control

I/O to the drive, the drive may fault when you reset the module.

Determine how your drive will respond before resetting an module.

Failure to observe this precaution could result bodily injury

and/or damage to equipment.

ATTENTION:

Comm Flt Action (10) and Idle Flt Action (11) let

you determine the action of the module and connected drive if

communications are disrupted. By default, these parameters fault

the drive. You can set these parameters so that the drive continues

to run. Precautions should be taken to ensure that the settings of

these parameters do not create a hazard of injury or equipment

damage. Failure to observe this precaution could result bodily

injury and/or damage to equipment.

ATTENTION:

When a system is configured for the first time, there

may be unintended or incorrect machine motion. Disconnect the

motor from the machine or process during initial system testing.

Failure to observe this precaution could result bodily injury

and/or damage to equipment.

Trademarks not belonging to Rockwell Automation are

property of their respective companies.

Contents

I

C

ONTENTS

Chapter 1 Introduction

1.1 ControlNet Module Features.......................................... 1-1

1.2 Related Documentation ................................................. 1-2

1.3 Conventions Used in This Manual ................................. 1-2

1.4 Getting Assistance from Reliance Electric..................... 1-2

Chapter 2 Getting Started

2.1 ControlNet Module Components ................................... 2-1

2.2 Required Equipment...................................................... 2-2

2.3 Installation Checklist...................................................... 2-3

Chapter 3 Installing the ControlNet Module

3.1 Preparing for an Installation........................................... 3-1

3.2 Commissioning the Module ........................................... 3-1

3.3 Connecting the Module to the Drive .............................. 3-2

3.4 Connecting the Module to the Network.......................... 3-5

3.5 Applying Power.............................................................. 3-6

Chapter 4 Configuring the ControlNet Module

4.1 Configuration Tools........................................................ 4-1

4.2 Using the LCD OIM to Configure the Module ................ 4-2

4.3 Setting the Node Address.............................................. 4-2

4.4 Setting the I/O Configuration ......................................... 4-3

4.5 Selecting Master-Slave.................................................. 4-4

4.6 Selecting Reference Adjust ........................................... 4-5

4.7 Setting a Fault Action..................................................... 4-5

4.7.1 Changing the Fault Action ................................... 4-6

4.7.2 Setting the Fault Configuration Parameters ........ 4-7

4.7.3 Resetting the Module........................................... 4-7

4.8 Viewing the Module Configuration ................................. 4-8

Chapter 5 RSNetWorx Configuration for PLC-5C Applications

5.1 Configuring a ControlNet Network: An Example............ 5-1

5.1.1 Installing and Registering EDS Files in

RSNetWorx ......................................................... 5-2

5.1.2 Configuring a Network with RSNetWorx.............. 5-7

5.1.3 Verifying Network Properties ............................. 5-18

II

ControlNet Communications Module

Chapter 6 PLC-5C Applications

6.1 About I/O Messaging ..................................................... 6-1

6.2 Understanding the I/O Image......................................... 6-2

6.3 Using Logic Command/Status ....................................... 6-4

6.4 Using Reference/Feedback ........................................... 6-5

6.5 Using Datalinks.............................................................. 6-5

6.5.1 Rules for Using Datalinks .................................... 6-5

6.5.2 32-Bit Parameters using 16-Bit Datalinks............ 6-6

6.6 Function of the Sample Program ................................... 6-7

6.7 Main Program (PLC-5C) ................................................ 6-8

6.8 About Explicit Messaging............................................. 6-12

6.8.1 Performing Explicit Messages ........................... 6-12

6.8.2 Explicit Messaging Examples ............................ 6-13

Chapter 7 ControlLogix Applications

7.1 Configuring a ControlLogix CNB Scanner ..................... 7-2

7.2 Function of the Sample Program ................................. 7-15

7.3 RSLogix 5000 Ladder Logic Program.......................... 7-17

7.4 About Explicit Messaging............................................. 7-19

7.4.1 Performing Explicit Messages ........................... 7-19

7.4.2 Explicit Messaging Examples ............................ 7-20

Chapter 8 Troubleshooting the ControlNet Module and Network

8.1 Understanding the Status Indicators.............................. 8-1

8.1.1 DRIVE Status Indicator........................................ 8-2

8.1.2 MS Status Indicator ............................................. 8-3

8.1.3 NET A and B Together ........................................ 8-4

8.1.4 NET A and B Independently ................................ 8-5

8.2 Module Diagnostic Items................................................ 8-6

8.3 Viewing and Clearing Events......................................... 8-8

Appendix A

Technical Specifications...................................................... A-1

Appendix B

ControlNet Module Parameters............................................ B-1

Appendix C

ControlNet Objects ............................................................... C-1

Appendix D

Logic Command/Status Words............................................. D-1

Glossary

..................................................................................Glossary-1

Index

.......................................................................................Index-1

Contents

III

List of Figures

Figure 2.1 – Components of the ControlNet Module .................................. 2-1

Figure 3.1 – Setting the Module’s Node Address ....................................... 3-2

Figure 3.2 – DPI Ports and Internal Interface Cables................................. 3-3

Figure 3.3 – Mounting the Module .............................................................. 3-4

Figure 3.4 – Typical ControlNet Network Wiring......................................... 3-5

Figure 4.1 – Accessing the ControlNet Parameters using the LCD OIM.... 4-2

Figure 4.2 – ControlNet Node Address Screen on an LCD OIM ................ 4-2

Figure 4.3 – I/O Configuration Screen on an LCD OIM .............................. 4-3

Figure 4.4 – Master-Slave Input Screen on an LCD OIM........................... 4-4

Figure 4.5 – Master-Slave Input Screen on an LCD OIM........................... 4-4

Figure 4.6 – Fault Action Screens on an LCD OIM..................................... 4-6

Figure 4.7 – Reset Screen on an LCD OIM................................................ 4-8

Figure 5.1 – Sample ControlNet Network ................................................... 5-1

Figure 5.2 – Rockwell Software EDS Wizard.............................................. 5-2

Figure 5.3 – EDS Wizard Option Screen .................................................... 5-3

Figure 5.4 – EDS Wizard Designation Screen............................................ 5-3

Figure 5.5 – EDS Files Installation Test Results Screen ............................ 5-4

Figure 5.6 – EDS Wizard Change Graphic Image Screen.......................... 5-5

Figure 5.7 – EDS Wizard Final Task Summary Screen.............................. 5-6

Figure 5.8 – EDS Wizard Completion Screen............................................. 5-6

Figure 5.9 – RSNetWorx for ControlNet DPI to ControlNet Folder

Example.................................................................................. 5-7

Figure 5.10 – RSNetWorx for ControlNet Screen....................................... 5-8

Figure 5.11 – Sample Browse for Network Dialog Box............................... 5-9

Figure 5.12 – Sample Network Displayed in RSNetWorx........................... 5-9

Figure 5.13 – Sample ControlNet Configuration Screen........................... 5-10

Figure 5.14 – Sample ControlNet Configuration Box................................ 5-11

Figure 5.15 – Example of Product Line after Drive Connection is

Selected ............................................................................. 5-11

Figure 5.16 – Online / Offline Mismatch Dialog Box ................................. 5-12

Figure 5.17 – Save Data Screen.............................................................. 5-12

Figure 5.18 – Scanlist Configuration Screen ........................................... 5-13

Figure 5.19 – Integer Files for ControlNet Communications Screen ........ 5-14

Figure 5.20 – Communicaiton Properties ................................................. 5-15

Figure 5.21 – Connection Properties: Electronic Keying Settings ............ 5-16

Figure 5.22 – Connection Properties: Details Settings ............................. 5-16

Figure 5.23 – ScanList Configuration: Mapped Nodes ............................. 5-17

Figure 5.24 – Save Configuration Dialog Box........................................... 5-17

Figure 5.25 – Save As File Box ................................................................ 5-18

Figure 5.26 – ControlNet Dialog Box ........................................................ 5-19

Figure 5.27 – ControlNet: Media Configuration Tab ................................. 5-19

Figure 5.28 – ControlNet: General Tab..................................................... 5-20

IV

ControlNet Communications Module

Figure 6.1 – Sample I/O Image with All I/O Enabled................................... 6-3

Figure 6.2 – Sample I/O Image with Only Logic/Reference and

Datalink B Enabled ................................................................. 6-4

Figure 6.3 – I/O Messaging......................................................................... 6-8

Figure 6.4 – I/O Messaging (Continued)..................................................... 6-9

Figure 6.5 – I/O Messaging (Continued)................................................... 6-10

Figure 6.6 – I/O Messaging (Continued)................................................... 6-11

Figure 6.7 – Explicit Message Process..................................................... 6-12

Figure 6.8 – Explicit Messaging ................................................................ 6-13

Figure 6.9 – CIO Get Attributes Scattered Screen.................................... 6-14

Figure 6.10 – CIO Set Attributes Scattered Screen .................................. 6-15

Figure 6.11 – CIO Get Attribute Single Screen......................................... 6-17

Figure 6.12 – CIO Set Attribute Single Screen ......................................... 6-18

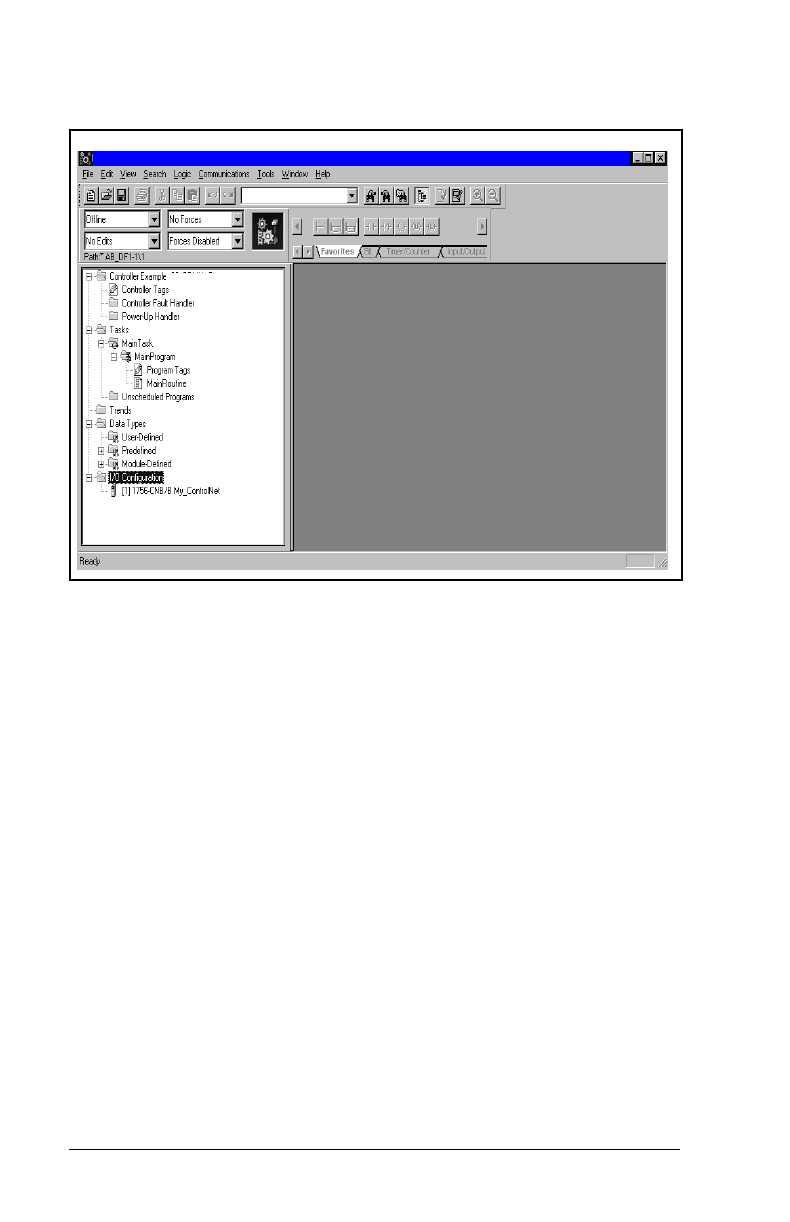

Figure 7.1 – RSLogix 5000: I/O Configuration Selection ............................ 7-2

Figure 7.2 – RSLogix 5000: New Module Selection.................................... 7-3

Figure 7.3 – Select Module Type: 1756-CNB/B Selection .......................... 7-3

Figure 7.4 – Module Properties: Name Selection ....................................... 7-4

Figure 7.5 – Module Properties: Controller-to-Module Behavior Screen .... 7-4

Figure 7.6 – Module Properties: Indentification/Status Screen................... 7-5

Figure 7.7 – Module Properties: Informational Screen................................ 7-5

Figure 7.8 – RSLogix 5000: I/O Configuration Folder................................. 7-6

Figure 7.9 – RSLogix 5000: New Module Selection Screen ....................... 7-7

Figure 7.10 – Select Module Type: Generic ControlNet Module Screen .... 7-8

Figure 7.11 – Module Properties: ControlNet Module Parameters ............. 7-9

Figure 7.12 – Module Properties: RPI Selection......................................... 7-9

Figure 7.13 – Module Properties: My ControlNet...................................... 7-10

Figure 7.14 – RSLogix: Configure Additional Nodes Screen .................... 7-10

Figure 7.15 – RSLogix 5000: Module-Defined Screen.............................. 7-11

Figure 7.16 – Download to the Controller Dialong Box............................. 7-11

Figure 7.17 – RSLogix: Attention Symbol ................................................. 7-12

Figure 7.18 – RSNetWorx for ControlNet Screen ..................................... 7-13

Figure 7.19 – RSLogix 5000: Example Without Attention Symbol............ 7-14

Figure 7.20 – RSLogix 5000: Connection Tree Without Attention Symbol7-15

Figure 7.21 – I/O Messaging..................................................................... 7-17

Figure 7.22 – I/O Messaging (Continued)................................................. 7-18

Figure 7.23 – Explicit Message Process................................................... 7-19

Figure 7.24 – Explicit Messaging .............................................................. 7-20

Figure 7.25 – Get_Attributes_Scattered Message Screen........................ 7-21

Figure 7.26 – Set_Attributes_Scattered Message Screen........................ 7-22

Figure 7.27 – Set_Attribute_Single Message Screen ............................... 7-24

Figure 7.28 – Get_Attributes_Single Message Screen............................. 7-25

Figure 8.1 – Status Indicators (Location on Drive May Vary)...................... 8-1

Figure 8.2 – VIewing and Clearing Events Using an LCD OIM................... 8-8

Contents

V

List of Tables

Table 2.1 – Equipment Shipped with the ControlNet Module ................... 2-2

Table 2.2 – Required User-Supplied Equipment ...................................... 2-2

Table 4.1 – Configuration Tools................................................................ 4-1

Table 4.2 – Selections for Drive Response to Communication Fault........ 4-6

Table 4.3 – Fault Configuration Parameters............................................. 4-7

Table 4.4 – Module Configuration Status Parameters.............................. 4-8

Table 5.1 – Input/Output Table............................................................... 5-14

Table 6.1 – Parameter Settings for the Sample Program......................... 6-7

Table 7.1 – Parameter Settings for the Sample Program....................... 7-16

Table 8.1 – DRIVE Status Indicator: State Definitions.............................. 8-2

Table 8.2 – MS Status Indicator: State Definitions ................................... 8-3

Table 8.3 – NET A and B Together: State Definitions .............................. 8-4

Table 8.4 – NET A and B Independently: State Definitions ...................... 8-5

Table 8.5 – Module Diagnostic Items........................................................ 8-6

Table 8.6 – Event Codes and Descriptions............................................... 8-8

VI

ControlNet Communications Module

Introduction

1-1

C

HAPTER

1

Introduction

The ControlNet

module (RECOMM-CNET) is an embedded

communication option for DPI

AC drives, such as the SP600

drive. The module is mounted in the drive and receives its required

power from the drive and from the network.

The module can be used with other products that implement DPI, a

peripheral communication interface. Refer to the documentation for

your product for specific information about how it works with the

module.

This manual is intended for qualified electrical personnel familiar

with installing, programming, and maintaining AC drives and

networks.

1.1 ControlNet Module Features

The ControlNet module features the following:

•

A number of configuration tools that can be used to configure the

module and connected drive. The tools include the LCD Operator

Interface Module (OIM) on the drive and drive-configuration

software such as VS Utilities

(version 1.01 or later)

.

•

Status indicators that report the status of the drive

communications, module, and network. They are visible both

when the cover is opened and when it is closed.

•

I/O, including Logic Command/Reference and up to four pairs of

Datalinks, that may be configured for your application using a

parameter.

•

Support of explicit messages.

•

User-defined fault actions that determine how the module and the

drive respond to communication disruptions on the network and

controllers in idle mode.

1-2

ControlNet Communications Module

1.2 Related Documentation

Refer to the following related publications as necessary for more

information. All of the publications are available from

http://www.theautomationbookstore.com.

•

D2-3485 SP600 AC Drive User Manual

•

D2-3488 VS Utilities Getting Results Manual

Online help installed with the software

•

9399-WAB32GR Getting Results with RSLinx

Online help installed with the software

•

9399-RL53GR RSLogix 5 Getting Results Guide

Online help installed with the software

•

9399-RL50GR RSLogix 500 Getting Results Guide

Online help installed with the software

•

9399-RLD300GR RSLogix 5000 Getting Results Guide

Online help installed with the software

•

9357-CNETL3 RSNetWorx for ControlNet Getting Results

Guide

Online help installed with the software.

1.3 Conventions Used in This Manual

The following convention is used throughout this manual:

•

Parameters are referenced as follows:

Parameter Name (Parameter Number)

For example: DPI Port (1)

1.4 Getting Assistance from Reliance

Electric

If you have any questions or problems with the products described

in this instruction manual, contact your local Reliance Electric sales

office.

For technical assistance, call 1-800-726-8112.

Getting Started

2-1

C

HAPTER

2

Getting Started

This chapter provides:

•

A description of the ControlNet module components

•

A list of parts shipped with the module

•

A list of user-supplied parts required for installing the module

•

An installation checklist

2.1 ControlNet Module Components

➊

Status Indicators Four LEDs that indicate the status of the

ControlNet channel(s), DPI, and the module. Refer

to chapter 8 for more information.

➋

DPI Connector A 20-pin, single-row shrouded male header. An

Internal Interface cable is connected to this

connector and a connector on the drive.

➌

Channel A BNC

Receptacle

Channel “A” BNC connection for the ControlNet

cable.

➍

Channel B BNC

Receptacle

Channel “B” BNC is an optional connection for the

redundnat ControlNet cable.

➎

ControlNet Node

Address Switches

Switches for setting the node address.

Figure 2.1 – Components of the ControlNet Module

➊

➋

➌➍

➎

2-2

ControlNet Communications Module

2.2 Required Equipment

Table 2.1 lists the equipment shipped with the ControlNet module.

When you unpack the module, verify that the package includes all of

these items.

Table 2.2 lists user-supplied equipment also required to install and

configure the ControlNet module.

Table 2.1 – Equipment Shipped with the ControlNet Module

Item Description

One RECOMM-CNET ControlNet module

A 2.54 cm (1 in) and a 15.24 cm (6 in) Internal Interface cable

(only one cable is needed to connect the module to the drive)

One grounding wrist strap

ControlNet Module User Manual (D2-3497)

Table 2.2 – Required User-Supplied Equipment

Item Description

A small flathead or Phillips screwdriver

Configuration tool, such as:

•

LCD OIM

•

VS Utilities (version 1.01 or later)

• with RECOMM-232 Serial Converter

RSNetWorx for ControlNet (version 3.00.00 or later)

Controller configuration software (for example, RSLogix 5,

RSLogix 500, or RSLogix 5000)

A PC connection to the ControlNet network, such as:

•

1784-PCC

•

1770-KFC

•

1784-KTCX

Getting Started

2-3

2.3 Installation Checklist

This section is designed to help experienced users start using the

ControlNet module. If you are unsure about how to complete a step,

refer to the referenced chapter.

✔ Step Action Refer to

❒

1

Review the safety precautions for the

module.

Throughout

this manual

❒

2

Verify that the drive is properly installed.

SP600 AC

Drive User

Manual

❒

3

Install the module.

Verify that the drive is not powered. Then,

connect the module to the network using a

ControlNet cable and to the drive using the

Internal Interface cable. Use the captive

screws to secure and ground the module to

the drive.

Chapter 3,

Installing the

ControlNet

Module

❒

4

Apply power to the module.

The module receives power from the drive.

Apply power to the drive. The status

indicators should be green. If they flash red,

there is a problem. Refer to chapter 8,

Troubleshooting the ControlNet Module and

the Network.

Chapter 3,

Installing the

ControlNet

Module

❒

5

Configure the module for your

application.

Set the parameters for the following features

as required by your application:

•

I/O configuration.

•

Fault actions.

Chapter 4,

Configuring

the

ControlNet

Module

❒

6

Apply power to the ControlNet master and

other devices on the network.

Verify that the master and network are

installed and functioning in accordance with

ControlNet standards, and then apply power

to them.

❒

7

Configure the scanner to communicate

with the module.

Use a network tool for ControlNet to

configure the master on the network.

Chapter 5,

RSNetWorx

Configuration

for PLC-5C

Applications

2-4

ControlNet Communications Module

❒

8

Create a ladder logic program.

Use a programming tool to create a ladder

logic program that enables you to do the

following:

•

Control the module and connected drive.

•

Monitor or configure the drive using Explicit

Messages.

Chapter 6,

PLC-5C

Applications

✔

Step Action Refer to

Installing the ControlNet Module

3-1

C

HAPTER

3

Installing the

ControlNet Module

Chapter 3 provides instructions for installing the module on an

SP600 drive.

3.1 Preparing for an Installation

Before installing the ControlNet module, verify that you have all

requirement equipment. Refer to chapter 2, Getting Started, for a

list of equipment.

3.2 Commissioning the Module

To commission the module, you must set a unique node address on

the network. (Refer to the Glossary for details about node

addresses.)

Important:

New settings are recognized only when power is

applied to the module or it is reset. If you change a

setting, cycle power or reset the module.

Important:

To guard against device malfunction, you must wear a

grounding wrist strap when installing the ControlNet

module.

Step 1. Set the ControlNet module’s node address by rotating the

node address switches to the desired value for each digit

as shown in figure 3.1.

Important:

Each node on the ControlNet network must have a

unique address.

!

ATTENTION:

The ControlNet module contains ESD-

(Electrostatic Discharge) sensitive parts that can be

damaged if you do not follow ESD control

procedures. Static control precautions are required

when handling the module. Failure to observe these

precautions could result in damage to equipment.

3-2

ControlNet Communications Module

Important:

The node address must be set before power is applied

because the module uses the node address it detects

when it first receives power. To change a node

address, you must set the new value and then remove

and reapply power to or reset the module.

3.3 Connecting the Module to the Drive

Step 1. Remove power from the drive.

Step 2. Use static control precautions.

Step 3. Connect the Internal Interface cable to the DPI port on the

drive and then to the DPI connector on the module. See

figure 3.2.

Setting Description

0 to 99 Node address used by the module if switches are enabled.

The default switch setting is 02.

Important:

If the address switch is set to “00”, the module

will use the setting of CN Addr Cfg (03) for the node

address. Refer to chapter 4, Configuring the ControlNet

Module, for more information.

Figure 3.1 – Setting the Module’s Node Address

2

1

0

9

8

3

4

5

6

7

2

1

0

9

8

3

4

5

6

7

Tens

Digit

Ones

Digit

Installing the ControlNet Module

3-3

Step 4. For 1-20 HP SP600 drives, fold the Internal Interface

cable behind the module and mount the module on the

drive using the four captive screws. See figure 3.3.

For 25-40 HP SP600 drives, mount the module on the

drive using the four captive screws to secure and ground

it to the drive.

➊

DPI Connector

➋

15.24 cm (6 in) Internal Interface cable

➌

2.54 cm (1 in) Internal Interface cable

Figure 3.2 – DPI Ports and Internal Interface Cables

➊

➋

➌

ControlNet Module

SP600 Drive

1-20 HP @ 460 V

SP600 Drive

25-40 HP @ 460 V

3-4

ControlNet Communications Module

Important:

All screws must be tightened since the module is

grounded through a screw.

Figure 3.3 – Mounting the Module

Adapter

Drive

SP600 1-20 HP Drive

Internal Interface Cable

Folded Behind the Module

and in Front of the Drive

Module

SP600 Drive

25-40 HP @ 460 V

Installing the ControlNet Module

3-5

3.4 Connecting the Module to the

Network

Step 1. Remove power from the drive.

Step 2. Use static control precautions.

Step 3. Route the ControlNet cable through the bottom of the

SP600 drive. (See figure 3.3.)

Step 4. Connect the ControlNet cable to the module.

A 1786-TPS (straight tap) is recommended.

See figure 3.4 for typical ControlNet network wiring.

!

ATTENTION:

The SP600 drive may contain high

voltages that can cause injury or death. Remove

power from the drive, and then verify power has

been discharged before installing or removing a

module. Failure to observe this precaution could

result in severe bodily injury or loss of life.

Figure 3.4 – Typical ControlNet Network Wiring

Scanner

SP600 Drive SP600 Drive

3-6

ControlNet Communications Module

3.5 Applying Power

Step 1. Close the door or reinstall the cover on the drive. The

status indicators can be viewed on the front of the drive

after power has been applied.

Step 2. Apply power to the drive. The module receives its power

from the connected drive. When you apply power to the

product for the first time, the status indicators should be

green or off after an initialization. If the status indicators

are red, refer to chapter 8.

Step 3. Apply power to the master device and other devices on

the network.

!

ATTENTION:

Unpredictable operation may occur

if parameter settings and switch settings are not

compatible with your application. Verify that

settings are compatible with your application

before applying power to the drive. Failure to

observe these precations could result in severe

bodily injury of loss of life.

Configuring the ControlNet Module

4-1

C

HAPTER

4

Configuring the

ControlNet Module

Chapter 4 provides instructions and information for setting the

parameters in the module.

For a complete list of parameters, refer to Appendix B, ControlNet

Module Parameters. For definitions of terms in this chapter, refer to

the Glossary.

4.1 Configuration Tools

The ControlNet module stores parameters and other information in

its own non-volatile memory. Therefore, you must access the

module to view and edit its parameters. Table 4.1 lists the tools that

can be used to access the module parameters.

Table 4.1 – Configuration Tools

Tool Refer to:

VS Utilities Software VS Utilities online help

LCD OIM Section 4.2

4-2

ControlNet Communications Module

4.2 Using the LCD OIM to Configure the

Module

Use the procedure in figure 4.1 to access the parameters on the

ControlNet module using the LCD OIM. If you are unfamiliar with

the operation of the LCD OIM, refer to the SP600 AC Drive User

Manual (D2-3485) for more information.

4.3 Setting the Node Address

If the node address switches are set to “00”, the value of CN Addr

Cfg (3) determines the node address.

Step 1. Set the value of CN Addr Cfg (3) to a unique node

address.

Step 2. Reset the module. Refer to section 4.7.3, Resetting the

Module.

Figure 4.1 – Accessing the ControlNet Parameters using the LCD OIM

P0: SP600

>>

Auto

Sto

pp

ed

Main Menu

Device Select

Use to select

RECOMM-CNET.

P0: SP600

>>

Auto

Sto

pp

ed

P5: RECOMM-CNET

>>

Auto

Sto

pp

ed

Main Menu

Parameters

Device: Port 0

SP600

RECOMM-CNET

Monitor

Lan

g

Edit the ControlNet

parameters usin

g

the

same techniques as for

drive parameters.

Use to hi

g

hli

g

ht

Device Select icon

Figure 4.2 – ControlNet Node Address Screen on an LCD OIM

Port 5 Device

RECOMM-CNET

Parameter #: 3

CN Addr Cfg

02

0 <> 99

Default = 02

Configuring the ControlNet Module

4-3

4.4 Setting the I/O Configuration

The I/O configuration determines the type of data sent to the drive.

This is a two-part process: enabling/disabling the data transmitted

betweeen the module and the drive, and identifying the data

transmitted between the module and the scanner.

Step 1. Enable or disable the data transmitted between the

module and the drive by setting the bits in DPI I/O Config

(13). A “1” enables the I/O. A “0” disables the I/O.

Bit 0 is the right-most bit. In figure 4.3, it is highlighted and equals

“1.”

Step 2. If Logic Command/Reference is enabled (default),

configure the parameters in the drive to accept the Logic

Command and Reference from the module. For example,

set Speed Ref A Sel (90) in an SP600 drive to “Network”

so that the drive uses the Reference from the module.

Also, verify that Logic Source Sel (89) is configured to

receive the desired logic from the module.

Step 3. If you enabled one or more Datalinks (optional), configure

parameters in the drive to determine the source and

destination of data in the Datalink(s). Also, ensure that the

ControlNet module is the only module using the enabled

Datalink(s).

Step 4. Reset the module. Refer to section 4.7.3, Resetting the

Module.

The module is ready to receive I/O from the master (i.e., scanner).

You must now configure the scanner to recognize and transmit I/O

to the module. Refer to chapter 5, RSNetWorx Configuration for

PLC-5C Applications, for more information.

Figure 4.3 – I/O Configuration Screen on an LCD OIM

Port 5 Device

RECOMM-CNET

Parameter #: 13

DPI I/O Config

xxxxxxxxxxx0000

1

Cmd/Ref b00

Bit Description

0 Logic Command/Reference (Default)

1 Datalink A

2 Datalink B

3 Datalink C

4 Datalink D

5 - 15 Not Used

4-4

ControlNet Communications Module

4.5 Selecting Master-Slave

A hierarchy determines the type of device with which the module

exchanges data. In a Master-Slave hierarchy, a module exchanges

data with a scanner.

To set a Master-Slave hierarchy

Step 1. Enable the desired I/O in DPI I/O Config (13). Refer to

figure 4.3.

Step 2. Set the bits in the M-S Input (25). This parameter

determines the data transmitted from the scanner to the

drive. A “1” enables the I/O. A “0” disables the I/O.

Bit 0 is the right-most bit. In figure 4.4, it is highlighted and equals

“1.”

Step 3. Set the bits in the M-S Output (26). This parameter

determines the data transmitted from the drive to the

scanner. A “1” enables the I/O. A “0” disables the I/O.

Bit 0 is the right-most bit. In figure 4.5, it is highlighted and equals

“1.”

Step 4. Reset the module. Refer section 4.7.3 for this procedure.

Figure 4.4 – Master-Slave Input Screen on an LCD OIM

Figure 4.5 – Master-Slave Input Screen on an LCD OIM

Bit Description

0 Logic Command/Reference (Default)

1 Datalink A Input

2 Datalink B Input

3 Datalink C Input

4 Datalink D Input

5 - 15 Not Used

Port 5 Device

RECOMM-CNET

Parameter #: 25

M-S Input

xxxx xxxx xxx0 000

1

Cmd/Ref b00

Bit Description

0 Status/Feedback (Default)

1 Datalink A Output

2 Datalink B Output

3 Datalink C Output

4 Datalink D Output

5 - 15 Not Used

Port 5 Device

RECOMM-CNET

Parameter #: 26

M-S Output

xxxxxxxxxxx0000

1

Status/Fdbk b00

Configuring the ControlNet Module

4-5

The module is ready to receive I/O from the master (i.e., scanner).

You must now configure the scanner to recognize and transmit I/O

to the module. Refer to chapter 5, RSNetWorx Configuration for

PLC-5C Applications.

4.6 Selecting Reference Adjust

Reference Adjust is the percent scaling factor for the Reference

from the Network and can be set from 0-200%. This allows the

drive’s Reference to either match the network Reference (=100%),

scale below the network Reference (<100%), or scale above the

network Reference (>100%).

4.7 Setting a Fault Action

By default, when communications are disrupted (for example, a

cable is disconnected) or the master is idle, the drive responds by

faulting if it is using I/O from the network.

You can configure a different response to communication

disruptions using Comm Flt Action (10) and a different response to

an idle scanner using Idle Flt Action (11).

!

ATTENTION:

Comm Flt Action (10) and Idle Flt

Action (11)

let you determine the action of the module

and connected Host product if the controller is idle

(for example, in program mode). These parameters

can be used to fault the Host product (default) or

perform another function such as allow the Host to

continue to run. Some ControlNet scanners may

operate differently when a controller is idle, which

could limit the Idle Fault Action’s operating states.

The Idle Flt Action should be verified when

commissioning the drive on the network by testing

the operation with the controller in idle.

4-6

ControlNet Communications Module

4.7.1 Changing the Fault Action

Set the values of Comm Flt Action (10)

and Idle Flt Action (11) to

the desired responses as shown in table 4.2. See figure 4.6 for

sample LCD OIM Fault Action screens.

Changes to these parameters take effect immediately. A reset is not

required.

Table 4.2 – Selections for Drive Response to Communication Fault

Value Action Description

0 Fault (default) The drive is faulted and stopped

(Default).

1 Stop The drive is stopped, but not

faulted.

2 Zero Data The drive is sent 0 for output data

after a communications disruption.

This does not command a stop.

3 Hold Last The drive continues in its present

state.

4 Send Flt Cfg The drive is sent the data that you

set in the fault configuration

parameters, Flt Cfg Logic (15)

through Flt Cfg D2 In (24).

Figure 4.6 – Fault Action Screens on an LCD OIM

Port 5 Device

RECOMM-CNET

Parameter #: 10

Comm Flt Action

0

Fault

Port 5 Device

RECOMM-CNET

Parameter #: 11

Idle Flt Action

0

Fault

Configuring the ControlNet Module

4-7

4.7.2 Setting the Fault Configuration Parameters

If you set Comm Flt Action (10) or Idle Flt Action (11) to “Send Flt

Cfg,” the values in the parameters shown in table 4.3 are sent to the

drive after a communications fault and/or idle fault occurs. You must

set these parameters to values required by your application.

Changes to these parameters take effect immediately. A reset is not

required.

4.7.3 Resetting the Module

Changes to switch settings or some module parameters require that

you reset the module before the new settings take effect. You can

reset the module by cycling power to the drive or by using Reset

Module (9).

Table 4.3 – Fault Configuration Parameters

Parameter

Number Name Description

15 Flt Cfg Logic A 16-bit value sent to the drive

for Logic Command.

16 Flt Cfg Ref A 32-bit value (0 to 4294967295)

sent to the drive as a Reference

or Datalink.

Important

: If the drive uses a

16-bit Reference or 16-bit

Datalinks, the most significant

word of the value must be set to

zero (0) or a fault will occur.

17 - 24 Flt Cfg x1 In

Flt Cfg x2 In

!

ATTENTION:

If the module is transmitting control

I/O to the drive, the drive may fault when you reset

the module. Determine how your drive will respond

before resetting a connected module. Failure to

observe this precaution could result in bodily injury

or damage to equipment.

4-8

ControlNet Communications Module

Set Reset Module (9) to Reset Module. See figure 4.7.

When you enter

1 (Reset Module)

, the module will be immediately

reset. When you enter

2 (Set Defaults)

, the module will set all

module parameters to their factory-default settings. The value of this

parameter will be restored to

0 (Ready)

after the module is reset or

resetting the defaults. The module should be reset after performing

a “Set Defaults.”

4.8 Viewing the Module Configuration

The parameters in table 4.4 provide information about how the

module is configured. You can view these parameters at any time.

Figure 4.7 – Reset Screen on an LCD OIM

Port 5 Device

RECOMM-CNET

Parameter #: 9

Reset Module

1

Reset Module

Value Description

0 Ready (Default)

1 Reset Module

2 Set Defaults

Table 4.4 – Module Configuration Status Parameters

No. Name and Description

Details

01

DPI Port

Port to which the module is connected. This will

usually be port 5.

Default: 5

Minimum: 0

Maximum: 7

Type: Read Only

02

DPI Data Rate

Data rate used by the drive. This data rate is set in

the drive and the module detects it.

Default: 0 = 125 K

Values 0 = 125 K

1 = 500 K

Type: Read Only

04

CN Addr Act

The actual network node address.

Default: 2

Minimum: 1

Maximum: 99

Type: Read Only

06

CN Rate Act

The actual network data rate.

Default: 0 = 5 Mbps

Values: 0 = 5 Mbps

Type: Read Only

07

Ref/Fdbk Size

Size of the Reference/Feedback. The drive

determines the size of the Reference/Feedback.

Default: 0 = 16-bit

Values: 0 = 16-bit

1 = 32-bit

Type: Read Only

08

Datalink Size

Size of each Datalink word. The drive determines

the size of Datalinks.

Default: 0 = 16-bit

Values: 0 = 16-bit

1 = 32-bit

Type: Read Only

Configuring the ControlNet Module

4-9

14

DPI I/O Active

I/O that the module is actively transmitting. The

value of this parameter will usually be equal to the

value of parameter 13 - DPI I/O Config.

Default: xxx0 0001

Bit Values: 0 = I/O disabled

1 = I/O enabled

Type: Read Only

Bit Definitions

0 = Cmd/Ref

1 = Datalink A

2 = Datalink B

3 = Datalink C

4 = Datalink D

5 = Not Used

6 = Not Used

7 = Not Used

25

M-S Input

Configures the I/O Data to be transferred from the

network to the drive.

Default: xxx0 0001

Bit Values: 0 = I/O disabled

1 = I/O enabled

Type: Read/Write

Reset Required: Yes

Bit Definitions

0 = Cmd/Ref

1 = Datalink A

2 = Datalink B

3 = Datalink C

4 = Datalink D

5 = Not Used

6 = Not Used

7 = Not Used

26

M-S Output

Configures the I/O Data to be transferred from the

drive to the network.

Default: xxx0 0001

Bit Values: 0 = I/O disabled

1 = I/O enabled

Type: Read/Write

Reset Required: Yes

Bit Definitions

0 = Cmd/Ref

1 = Datalink A

2 = Datalink B

3 = Datalink C

4 = Datalink D

5 = Not Used

6 = Not Used

7 = Not Used

27

Ref Adjust

Percent scale factor for the Reference from the

Network.

Default: 100.00

Minimum: 0.00

Maximum: 200.00

Type: Read/Write

Reset Required: No

Table 4.4 – Module Configuration Status Parameters

No. Name and Description

Details

Bit

Default

10000xxx

01234576

Bit

Default

10000xxx

01234576

Bit

Default

10000xxx

01234576

4-10

ControlNet Communications Module

RSNetWorx Configuration for PLC-5C Applications

5-1

C

HAPTER

5

RSNetWorx Configuration

for PLC-5C Applications

This chapter provides information for using RSNetWorx for

ControlNet to configure a PLC-5C controller to communicate with

the RECOMM-CNET ControlNet module.

RSNetWorx for ControlNet is a 32-bit Windows application for

configuring ControlNet networks. After installing and configuring the

module, RSNetWorx is used to configure the controller to recognize

and communicate with the module.

Before configuring the controller, your PC must be:

•

Connected to the ControlNet network using a 1784-PCC,

1770-KFC, or similar device.

•

Running RSNetWorx with RSLinx communications.

5.1 Configuring a ControlNet Network:

An Example

In this example, we will be configuring two SP600 drives to be

Node 2 and Node 3 on a ControlNet network. This chapter

describes the steps to configure a simple network as shown in

figure 5.1.

Figure 5.1 – Sample ControlNet Network

SP600 Drive

Node 2

SP600 Drive

Node 3

Scanner

5-2

ControlNet Communications Module

5.1.1 Installing and Registering EDS Files in

RSNetWorx

This section needs to be performed only if new EDS (Electronic

Data Sheet) files need to be added to RSNetWorx. The latest EDS

files can be obtained at:

http://www.reliance.com/prodserv/standriv/networks.

In the

T

ools

menu, select

EDS Wizard

and click

Next (

figure 5.2

)

.

Step 1. The EDS Wizard can be used to install (register) new

EDS files to the RSNetWorx database, remove

(unregister) EDS files from the RSNetWorx database, and

change the graphic icon used to represent the device.

Select

Register an EDS file(s)

and click

N

ext

(figure

5.3).

Figure 5.2 – Rockwell Software EDS Wizard

RSNetWorx Configuration for PLC-5C Applications

5-3

Step 2. The EDS Wizard allows for registering single or multiple

EDS files. Click

B

rowse

and locate where your EDS files

are located. In our example (figure 5.4), multiple EDS files

are registered from a directory on the hard drive.

Figure 5.3 – EDS Wizard Option Screen

Figure 5.4 – EDS Wizard Designation Screen

5-4

ControlNet Communications Module

Step 3. The EDS Wizard will install and test the EDS files. A

green check mark next to each file indicates success.

Click

N

ext

to continue (figure 5.5).

Figure 5.5 – EDS Files Installation Test Results Screen

RSNetWorx Configuration for PLC-5C Applications

5-5

Step 4. The graphic images for each EDS file are displayed and

can be changed if desired. Click

N

ext

to continue (figure

5.6).

Figure 5.6 – EDS Wizard Change Graphic Image Screen

SP600

5-6

ControlNet Communications Module

Step 5. Click

N

ext

to register the EDS files (figure 5.7).

Step 6. The EDS files have been installed and registered. Click

F

inish

to return to the main RSNetWorx screen (figure

5.8).

Figure 5.7 – EDS Wizard Final Task Summary Screen

You would like to register the following device:

SP600

Figure 5.8 – EDS Wizard Completion Screen

RSNetWorx Configuration for PLC-5C Applications

5-7

Step 7. Click on the

DPI to ControlNet

folder in the Hardware

window to view the EDS files that have been installed to

the RSNetWorx database (figure 5.9).

5.1.2 Configuring a Network with RSNetWorx

The main screen for RSNetWorx consists of several windows:

•

The Network Usage View displays current and pending values

associated with the ControlNet network configuration.

•

A Hardware View displays a list of all network hardware currently

available to RSNetWorx software.

•

The Favorites View displays a list of hardware that is frequently

used when working with the current RSNetWorx configuration.

•

The Graph View shows a pictorial representation of all the

hardware used in the current RSNetWorx configuration.

•

The Message View displays a log of messages which are listed

from top to bottom, newest to oldest. This view may contain

informational, warning, and/or error messages.

Figure 5.9 – RSNetWorx for ControlNet DPI to ControlNet Folder Example

SP600

5-8

ControlNet Communications Module

The various views can be displayed or closed by using the

V

iew

menu. In figure 5.10,

the Network Usage, Hardware and Graphic

views are displayed while the Message and Favorites views are

closed.

Step 1. Click the on-line icon to browse the network.

Step 2. Select the ControlNet network access method and click

OK. In this example, RSNetWorx will use the 1784-PCC

to access the ControlNet network (figure 5.11).

Figure 5.10 – RSNetWorx for ControlNet Screen

RSNetWorx Configuration for PLC-5C Applications

5-9

.

RSNetWorx starts browsing the ControlNet network for nodes and

builds the graphic representation of the network (figure 5.12).

Figure 5.11 – Sample Browse for Network Dialog Box

Figure 5.12 – Sample Network Displayed in RSNetWorx

5-10

ControlNet Communications Module

Step 3. When the network browse is complete, a graphical view of

the network is displayed. In this example (figure 5.13), the

ControlNet network consists of a PLC-5C/40C controller,

two SP600 drives, and a PC using a 1784-PCC.

The symbol indicates the device shown on the

network does not exist in the configuration file, but it was

found on the network. Double-click on the PLC-5C/40C

icon.

Step 4. The ControlNet configuration box displays information

about each node (figure 5.14). Click

OK.

Figure 5.13 – Sample ControlNet Configuration Screen

SP600 SP600

RSNetWorx Configuration for PLC-5C Applications

5-11

Step 5. The ControlNet module must be configured on the

ControlNet network so the controller can communicate

with it. Click the Edits Enabled check-box (figure 5.15).

Figure 5.14 – Sample ControlNet Configuration Box

Figure 5.15 – Example of Product Line after Drive Connection is Selected

SP600 SP600

5-12

ControlNet Communications Module

Step 6. If the On-line / Off-line Mismatch dialog box appears, click

OK to use the on-line data (figure 5.16). If prompted to

save, save the data (figure 5.17).

Important:

During the save process, RSNetWorx will execute the

browse function. Allow RSNetWorx to complete the

browse (1-99 nodes), even if you already see the entire

network. Canceling the browse early may cause an

improper scheduling of I/O.

Step 7. Right-click on the controller’s icon (PLC-5C) and select

S

CANlist Configuration

. The Scanlist Configuration

screen (figure 5.18), is used to configure the controller to

communicate with the nodes.

Figure 5.16 – Online / Offline Mismatch Dialog Box

Figure 5.17 – Save Data Screen

RECOMM-CNET Example.XC

RSNetWorx Configuration for PLC-5C Applications

5-13

..

Step 8. Enter the Integer files to be used for ControlNet

communications (figure 5.19). In this example, N9 is the

Data Input File, N10 is the Data Output File, N11 is the

Status File, and N13 is the Configuration File. Double-

click the Node 2 row (SP600 drive).

Figure 5.18 – Scanlist Configuration Screen

SP600

SP600

5-14

ControlNet Communications Module

Step 9. Enter the input and output size for the node on the

network. The number of words selected depends on the

I/O to be communicated with the node. In this example,

the Node 2 SP600 is set for all I/O enabled which equates

to 10 words of I/O (table 5.1).

Important:

The size of the Reference (Ref/Fdbk Size (7)) and

Datalinks (Datalink Size (8)) will affect the size you

configure for the network I/O. For example, 32-bit

Datalinks requires twice as many words as 16-bit

Datalinks. Depending on your application, the

configured I/O size may vary.

Figure 5.19 – Integer Files for ControlNet Communications Screen

Table 5.1 – Input/Output Table

Words Input to PLC-5C Output to PLC-5C

0-1 Logic Command /

Reference

Logic Status /

Feedback

2-3 Datalinks A1 & A2 Out Datalinks A1 & A2 In

4-5 Datalinks B1 & B2 Out Datalinks B1 & B2 In

6-7 Datalinks C1 & C2 Out Datalinks C1 & C2 In

8-9 Datalinks D1 & D2 Out Datalinks D1 & D2 In

SP600

SP600

RSNetWorx Configuration for PLC-5C Applications

5-15

Note the values in the Input Address and Output Address fields.

These are needed to develop a ladder program.

Step 10. Enter the desired Requested Packet Interval (RPI) and

note the value (figure 5.20). Ensure that this value is

equal to or greater than the value that will be set later for

Network Update Time (NUT). The Actual Packet Interval

(API) may vary from the Requested Packet Interval.

Step 11. Click the

Electronic Keying

tab. Electronic Keying is

used to determine the criteria used for the scanner to

establish a connection to a node. Select the settings

according to your application needs (figure 5.21).

Figure 5.20 – Communicaiton Properties

SP600

5-16

ControlNet Communications Module

Step 12. Click the

Details

(figure 5.22)

tab. The availability of

choosing connection options are determined by the EDS

file for the node. Click

OK

.

Figure 5.21 – Connection Properties: Electronic Keying Settings

Figure 5.22 – Connection Properties: Details Settings

RSNetWorx Configuration for PLC-5C Applications

5-17

Step 13. Repeat steps 9-12 for additional nodes. When complete,

all of the nodes should be mapped (figure 5.23).

Step 14. Click

F

ile

/

Save

to save the project (figure 5.24). If

prompted to optimize and re-write schedule for all

connections, click

O

K.

Figure 5.23 – ScanList Configuration: Mapped Nodes

Figure 5.24 – Save Configuration Dialog Box

SP600

SP600

5-18

ControlNet Communications Module

Step 15. Enter a file name and click

S

ave

. The project is now

saved for future use.

5.1.3 Verifying Network Properties

In the

N

etwork

menu, select

Properties

to display the ControlNet

dialog box (figure 5.26). Verify:

•

The number in the

Max S

cheduled Address

field is higher than

or equal to the highest node number that will perform I/O

messaging.

•

The number in the

Max U

nscheduled Address

field is higher

than or equal to the highest node number on the network.

•

The correct type of media redundancy is selected in the

M

edia

Redundancy

field.

Important:

The value in the

Network Update T

ime (ms)

field is

5 ms or greater. Do not set lower than 5 ms. The NUT

must be set equal or lower than the RPI times set for

the devices on the network.

Figure 5.25 – Save As File Box

RECOMM-CNET Example.XC

RSNetWorx Configuration for PLC-5C Applications

5-19

Step 16. If a special media configuration is required (e.g.,

repeater), select the

Media Configuration

tab (figure

5.27) and make the appropriate changes. Refer to the

RSNetWorx on-line help for more information.

Figure 5.26 – ControlNet Dialog Box

Figure 5.27 – ControlNet: Media Configuration Tab

5-20

ControlNet Communications Module

Step 17. If desired, select the

General

tab and enter a name and

description for the network (figure 5.28). Click

OK

.

Step 18. In the

N

etwork

menu, select

Save

the properties and

download them to the PLC. The module(s) are now

mapped on the network and the controller will

communicate with it.

Figure 5.28 – ControlNet: General Tab

RECOMM-CNET ControlNet demonstration

program using two SP600 demo units.

PLC-5C Applications

6-1

C

HAPTER

6

PLC-5C Applications

Chapter 6 provides information and examples that explain how to

use I/O Messaging and Explicit Messaging to control, configure, and

monitor an SP600 drive using a PLC-5C.

6.1 About I/O Messaging

I/O messaging is used to transfer the data which controls the SP600

drive and sets its Reference. I/O can also be used to transfer data to

and from Datalinks in SP600 drives.

The ControlNet module provides options for configuring and using

I/O, including the following:

•

The size of I/O can be configured by enabling or disabling the

Logic Command/Reference and Datalinks.

Chapter 4, Configuring the ControlNet Module, and Chapter 5,

RSNetWorx Configuration for PLC-5C Applications, discuss how to

configure the module and scanner on the network for these options.

The Glossary defines the different options. This chapter discusses

how to use I/O after you have configured the module and scanner.

!

ATTENTION:

The examples in this publication are

intended solely for purposes of example. There are

many variables and requirements with any

application. Rockwell Automation does not assume

responsibility or liability (to include intellectual

property liability) for actual use of the examples

shown in this publication. Failure to observe this

precaution could result in bodily injury or damage to

equipment.

6-2

ControlNet Communications Module

6.2 Understanding the I/O Image

The terms

input

and

output

are defined from the scanner’s point of

view. Therefore, output I/O is data that is output from the scanner

and consumed by the ControlNet module. Input I/O is status data

that is produced by the module and consumed as input by the

scanner.

The I/O image table will vary based on the following:

•

Size (either 16-bit or 32-bit) of the Reference/Feedback (Ref/Fdbk

Size (07)) words and Datalink words used by the drive.

•

Size (either 16-bit or 32-bit) of the Datalink words (Datalink Size

(08)). If all I/O is not enabled, the image table is truncated. The

image table always uses consecutive words starting at word 0.

Figure 6.1 illustrates an example of an I/O image with 16-bit

words.The configuration is shown to illustrate utilizing 10 words of

inputs and 10 words of outputs. Depending on your application

needs, this may vary.

PLC-5C Applications

6-3

An image that uses 32-bit words for Reference and Datalinks A and

D would change the I/O image in figure 6.1 as follows:

Figure 6.1 – Sample I/O Image with All I/O Enabled

Controller

Scanner

Module SP600 Drive

ControlNet

DPI

Output

Image

(Write)

Message

Handler

Input

Image

(Read)

0 Logic Status

1 Feedback

2 Datalink Out A1

3 Datalink Out A2

4 Datalink Out B1

5 Datalink Out B2

6 Datalink Out C1

7 Datalink Out C2

8 Datalink Out D1

9 Datalink Out D2

0 Logic Command

1 Reference

2 Datalink In A1

3 Datalink In A2

4 Datalink In B1

5 Datalink In B2

6 Datalink In C1

7 Datalink In C2

8 Datalink In D1

9 Datalink In D2

Logic Status

Feedback

Data Out A1

Data Out A2

Data Out B1

Data Out B2

Data Out C1

Data Out C2

Data Out D1

Data Out D2

Word and I/O

Message

Handler

Message

Handler

Message

Buffer

Message

Buffer

Message

Handler

Logic Command

Reference

Data In A1

Data In A2

Data In B1

Data In B2

Data In C1

Data In C2

Data In D1

Data In D2

Word I/O Word I/O

0 Logic Command/Status 8 - 11 Datalink B1/B2

1 Pad Word 12 - 15 Datalink C1/C2

2 - 3 Reference/Feedback 16 - 19 Datalink D1/D2

4 - 7 Datalink A1/A2

6-4

ControlNet Communications Module

Figure 6.2 illustrates an example of an I/O image that does not use

all of the I/O data. Only the Logic Command/Reference and

Datalink B are enabled. In this example, the Reference is a 32-bit

word, and Datalinks are 16-bit words.

6.3 Using Logic Command/Status

When enabled, the Logic Command/Status word is always word 0 in

the I/O image. The

Logic Command

is a 16-bit word of control

produced by the scanner and consumed by the module. The

Logic

Status

is a 16-bit word of status produced by the module and

consumed by the scanner.

This manual contains the bit definitions for compatible products

available at the time of publication in Appendix D, Logic Command/

Status Words. For other products, refer to their documentation.

Figure 6.2 – Sample I/O Image with Only Logic/Reference and Datalink B

Enabled

Controller

Scanner Module SP600 Drive

ControlNet

DPI

Output

Image

(Write)

Input

Image

(Read)

0 Logic Status

1 Pad Word

2 Feedback (LSW)

3 Feedback (MSW)

4 Datalink Out B1

5 Datalink Out B2

0 Logic Command

1 Pad Word

2 Reference (LSW)

3 Reference (MSW)

4 Datalink In B1

5 Datalink In B2

Word and I/O

Logic Command

Reference

Data In A1

Data In A2

Data In B1

Data In B2

Data In C1

Data In C2

Data In D1

Data In D2

Logic Status

Feedback

Data Out A1

Data Out A2

Data Out B1

Data Out B2

Data Out C1

Data Out C2

Data Out D1

Data Out D2

LSW = Least Signicant Word (Bits 15 - 0)

MSW = Most Significant Word (Bits 31 - 16)

PLC-5C Applications

6-5

6.4 Using Reference/Feedback

The

Reference

(16 bits or 32 bits) is produced by the controller and

consumed by the module. The

Feedback

(16 bits or 32 bits) is

produced by the module and consumed by the controller. The size

of the Reference/Feedback is determined by the drive and displayed

in Ref/Fdbk Size (07) in the module.

6.5 Using Datalinks

A Datalink is a mechanism used by SP600 drives to transfer data to

and from the controller. Datalinks allow a parameter value to be

changed without using an Explicit Message.

When enabled, each Datalink consumes either two 16-bit or 32-bit

words in both the input and output image depending on its size. The

size of Datalinks (16-bit words or 32-bit words) is determined by the

drive and displayed in Datalink Size (08) in the module.

6.5.1 Rules for Using Datalinks

•

Each set of Datalink parameters in an SP600 drive can be used

by only one module. If more than one module is connected to a

single drive, multiple modules must not try to use the same

Datalink.

•

Parameter settings in the drive determine the data passed

through the Datalink mechanism. Refer to the documentation for

your drive.

•

When you use a Datalink to change a value, the value is not

written to the Non-Volatile Storage (NVS). The value is stored in

volatile memory and lost when the drive loses power.

Size Valid Values In I/O Image Example

16-bit -32768 to 32767 Word 1 Figure 6.1

32-bit -2147483648 to 2147483647 Word 2 and Word 3 Figure 6.2

6-6

ControlNet Communications Module

6.5.2 32-Bit Parameters using 16-Bit Datalinks

To read (and/or write) a 32-bit parameter using 16-bit Datalinks,

typically both Datalinks (x1 and x2) are set to the 32-bit parameter.

For example, to read Elapsed MWh (9)

in an SP600 drive, both

Datalink A1 and A2 are set to “9.” Datalink A1 will contain the least

significant word (LSW) and Datalink A2 the most significant word

(MSW). In this example, the parameter 9 value of 5.8 MWh is read

as a “58” in Datalink A1.

Regardless of the Datalink combination, x1 will always contain the

LSW and x2 will always contain the MSW. In the following examples

Power Up Marker (242) contains a value of 88.4541 hours.

32-bit data is stored in binary as follows:

Example:

Power Up Marker (242) = 88.4541 hours

MSW = 13

decimal

= 1101

binary

= 2

19

+ 2

18

+ 2

16

= 851968

LSW = 32573

851968 + 32573 = 884541

Datalink

Most/Least

Significant Word Parameter

Data

(decimal)

A1 LSW 9 58

A2 MSW 9 0

Datalink

Most/Least

Significant Word Parameter

Data

(decimal)

A1 LSW 242 32573

A2 - Not Used - 0 0

Datalink

Most/Least

Significant Word Parameter

Data

(decimal)

A1 - Not Used - 0 0

A2 MSW 242 13

Datalink

Most/Least

Significant Word Parameter

Data

(decimal)

A2 MSW 242 13

B1 LSW 242 32573

MSW

2

31

through 2

16

LSW

2

15

through 2

0

PLC-5C Applications

6-7

6.6 Function of the Sample Program

The program performs the following actions:

•

Obtains Logic Status information from the drive.

•

Uses the Logic Command to control the drive (for example, start,

stop).

•

Sends a Reference to the drive and receives Feedback from the

drive.

•

Sends/Receives Datalink data to/from the drive.

Module Settings for the Sample Program

•

Nodes 2 and 3.

•

See Chapter 5, RSNetWorx Configuration for PLC-5C

Applications.

Parameter Settings for the Sample Program

Logic Command/Status Words

These examples use the Logic Command word and Logic Status

word for SP600 drives. Refer to Appendix D, Logic Command/

Status Words to view these. The definition of the bits in these words

may vary if you are using a different DPI product. Refer to the

documentation for your drive.

Table 6.1 – Parameter Settings for the Sample Program

Device Parameter Name Value Description

SP600 Drive

90 Speed Ref A Sel 22 ‘Network’ (RECOMM-CNET)

300 Data In A1 140 Points to 140 (Accel Time 1)

301 Data In A2 142 Points to 142 (Decel Time 1)

302 Data In B1 100 Points to 100 (Jog Speed)

303 Data In B2 155 Points to 155 (Stop Mode A)

310 Data Out A1 140 Points to 140 (Accel Time 1)

311 Data Out A2 142 Points to 142 (Decel Time 1)

312 Data Out B1 100 Points to 100 (Jog Speed)

313 Data Out B2 155 Points to 155 (Stop Mode A)

13 DPI I/O Cfg xxx1 1111 Enables Cmd/Ref, Datalinks A-D

RECOMM-CNET

25 M-S Input xxx1 1111 Configures the I/O Data to be

transferred from the network to the

drive.

26 M-S Output xxx1 1111 Configures the I/O Data to be

transferred from the drive to the

network.

6-8

ControlNet Communications Module

6.7 Main Program (PLC-5C)

Figure 6.3 – I/O Messaging

There is an operator station wired into the local rack as follows:

I:000/0 Start (Normally Open Pushbutton)

I:000/1 Stop (Normally Closed Pushbutton)

I:000/2 Clear Faults (Normally Open Pushbutton)

I:000/3 Forward / Reverse Selector Switch

I:001 Operator Speed Reference

O:000/0 Drive Ready

O:000/1 Drive Active

O:000/2 Drive Faulted

O:001 Operator Speed Feedback

The 20-COMM-C on the PowerFlex 70 drive is mapped as follows:

N9:0 Logic Status N10:0 Logic Command

N9:1 Feedback N10:1 Reference

N9:2 Datalink A1 Out N10:2 Datalink A1 In

N9:3 Datalink A2 Out

N10:3 Datalink A2 In

N9:4 Datalink B1 Out N10:4 Datalink B1 In

N9:5 Datalink B2 Out N10:5 Datalink B2 In

N9:6 Datalink C1 Out N10:6 Datalink C1 In

N9:7 Datalink C2 Out N10:7 Datalink C2 In

N9:8 Datalink D1 Out N10:8 Datalink D1 In

N9:9 Datalink D2 Out N10:9 Datalink D2 In

0000

I:000

0

Operator

Start

Pushbutton

N10:0

1

Drive

Logic Command

START

0001

I:000

1

Operator

Stop

Pushbutton

N10:0

0

Drive

Logic Command

STOP

The RECOMM-CNET on the SP600 drive is mapped as follows:

PLC-5C Applications

6-9

Figure 6.4 – I/O Messaging (Continued)

002

I:000

2

Operator

Clear Faults

Pushbutton

N10:0

3

Drive

Logic Command

CLEAR FAULTS

003

I:000

3

Operator

Fwd / Rev

Selector Switch

N10:0

4

Drive

Logic Command

FORWARD

004

I:000

3

Operator

Fwd / Rev

Selector Switch

N10:0

5

Drive

Logic Command

REVERSE

005

N9:0

0

Drive

READY

Status

Bit

O:000

0

Operator

Drive Ready

Status

Display

006

N9:0

1

Drive

ACTIVE

Status

Bit

O:000

1

Operator

Drive Active

Status

Display

6-10

ControlNet Communications Module

Figure 6.5 – I/O Messaging (Continued)

007

N9:0

7

Drive

FAULTED

Status

Bit

O:000

2

Operator

Drive Faulted

Status

Display

This rung moves the Speed Reference from the operator station to the

drive.

008

MOV

Move

Source I:001

0<

Dest N10:1

0<

MOV

The rung moves the Speed Feedback from the drive to the operator

station.

009

MOV

Move

Source N9:1

0<

Dest O:001

0<

MOV

This rung moves Datalink data (N7) to the drive, where it is moved

into parameters.

010

COP

Copy File

Source #N7:0

Dest #N10:2

Length 8

COP

Drive

Datalink A1 In

PLC-5C Applications

6-11

Figure 6.6 – I/O Messaging (Continued)

This rung moves Datalink data from the drive to file N7.

011

COP

Copy File

Source #N9:2

Dest #N7:10

Length 8

COP

This rung executes the messaging logic.

012

JSR

Jump To Subroutine

Prog File Number U:3

JSR

013

END

6-12

ControlNet Communications Module

6.8 About Explicit Messaging

Explicit Messaging is used to transfer data that does not require

continuous updates. With Explicit Messaging, you can configure

and monitor a slave device’s parameters on the ControlNet network.

6.8.1 Performing Explicit Messages

Important:

There are five basic events in the Explicit Messaging

process defined below. The details of each step will

vary depending on the controller. Refer to the

documentation for your controller.

Important:

The scanner module may be integrated with the

controller (e.g., PLC-5C).

➊

➍

➎

Retrieve Parameter

Message Response

Complete Parameter

Message

Set up and send

Parameter Message

➋

➌

➊

Format the required data and set up the ladder

logic program to send an Explicit Message

request to the scanner module (download).

➋

The scanner module transmits the Explicit

Message Request to the slave device over the

ControlNet network.

➌

The slave device transmits the Explicit Message

Response back to the master.

➍

The controller retrieves the Explicit Message

Response.

➎

The Explicit Message is complete.

Figure 6.7 – Explicit Message Process

PLC-5C Applications

6-13

The ControlNet I/O Transfer (CIO) instruction is used to send

Explicit Messages. For PLC-5C controllers before Series F Revision

C, the available services you should use are Get Attribute Single,

Get Attribute All, Set Attribute Single, or Set Attribute All. Series F

Revision C (or later) allow for more complex messages using a new

Generic Bi-Directional communication command.

6.8.2 Explicit Messaging Examples

A Get Attributes Scattered message allows for reading multiple

parameters that may or may not be in sequential order (figure 6.9).

•

A Service Code of “4B” indicates the Get_Attributes_Scattered

service (see page C-20, Object Specific Services).).

•

A Class Number of “93” indicates accessing the DPI Parameter

Object (see page C-16, DPI Parameter Object).

•

An Instance Number of “0” accesses the Class Attributes (see

page C-16, Instances).

•

N13:0-11 contains the request message and N14:0-11 contains

the response message (see page C-20, Format for

Get_Attributes_Scattered Service).

Figure 6.8 – Explicit Messaging

This rung sends a message to the drive over ControlNet and receives

file N13 while the response data is placed in data file N14.

the response from the drive. The message to be sent is built in data

000

N7:2

0

User Logic

Message

Initiate

EN

DN

ER

CIO

ControlNet I/O Transfer

Control CT12:0

Setup Screen

CIO

001

END

6-14

ControlNet Communications Module

Get Attributes Scattered Example request and response Data:

Request Data

Figure 6.9 – CIO Get Attributes Scattered Screen

N13:0 12 Parameter Number = 12

N13:1 0 (Pad Word)

N13:2 0 (Pad Word)

N13:3 11 Parameter Number = 11

N13:4 0 (Pad Word)

N13:5 0 (Pad Word)

N13:6 10 Parameter Number = 10

N13:7 0 (Pad Word)

N13:8 0 (Pad Word)

N13:9 9 Parameter Number = 9

N13:10 0 (Pad Word)

N13:11 0 (Pad Word)

PLC-5C Applications

6-15

Response Data

A Set Attributes Scattered message is used to write multiple

parameters that may or may not be in sequential order (figure 6.10).

•

A Service Code of “4C” indicates the Set_Attributes_Scattered

service (see page C-19, Object Specific Services).

N14:0 12 Parameter Number = 12

N14:1 3333 Value = 333.3VDC

N14:2 0 (Pad Word)

N14:3 11 Parameter Number = 11

N14:4 0 Value = 0.0Hz

N14:5 0 (Pad Word)