INTERNATIONAL CONFERENCE ON HARMONISATION OF TECHNICAL

REQUIREMENTS FOR REGISTRATION OF PHARMACEUTICALS FOR HUMAN

USE

ICH HARMONISED TRIPARTITE GUIDELINE

SPECIFICATIONS: TEST PROCEDURES AND ACCEPTANCE CRITERIA

FOR NEW DRUG SUBSTANCES AND NEW DRUG PRODUCTS:

CHEMICAL SUBSTANCES

Q6A

Current Step 4 version

dated 6 October 1999

This Guideline has been developed by the appropriate ICH Expert Working Group and

has been subject to consultation by the regulatory parties, in accordance with the ICH

Process. At Step 4 of the Process the final draft is recommended for adoption to the

regulatory bodies of the European Union, Japan and USA.

Q6A

Document History

First

Codification

History

Date

New

Codification

November

2005

Q6A

Approval by the Steering Committee under Step 2

and release for public consultation.

18

July

1997

Q6A

Current Step 4 version

Q6A

Approval by the Steering Committee under Step 4 and

recommendation for adoption to the three ICH

regulatory bodies.

6

October

1999

Q6A

i

SPECIFICATIONS: TEST PROCEDURES AND ACCEPTANCE CRITERIA

FOR NEW DRUG SUBSTANCES AND NEW DRUG PRODUCTS:

CHEMICAL SUBSTANCES

ICH Harmonised Tripartite Guideline

Having reached Step 4 of the ICH Process at the ICH Steering Committee meeting

on 6 October 1999, this guideline is recommended for

adoption to the three regulatory parties to ICH

TABLE OF CONTENTS

1. INTRODUCTION ................................................................................................... 1

1.1 Objective of the Guideline ........................................................................... 1

1.2 Background .................................................................................................. 1

1.3 Scope of the Guideline ................................................................................. 1

2. GENERAL CONCEPTS ........................................................................................ 2

2.1 Periodic or Skip Testing ............................................................................... 2

2.2 Release vs. Shelf-life Acceptance Criteria ................................................... 2

2.3 In-process Tests ........................................................................................... 3

2.4 Design and Development Considerations ................................................... 3

2.5 Limited Data Available at Filing................................................................. 3

2.6 Parametric Release ...................................................................................... 4

2.7 Alternative Procedures ................................................................................ 4

2.8 Pharmacopoeial Tests and Acceptance Criteria ......................................... 4

2.9 Evolving Technologies .................................................................................. 5

2.10 Impact of Drug Substance on Drug Product Specifications ....................... 5

2.11 Reference Standard ...................................................................................... 5

3. GUIDELINES ......................................................................................................... 5

3.1 Specifications: Definition and Justification ................................................ 5

3.1.1 Definition of Specifications .......................................................... 5

3.1.2 Justification of Specifications ...................................................... 6

Specifications: New Chemical Drug Substances and Products

ii

3.2 Universal Tests / Criteria ............................................................................. 6

3.2.1 New Drug Substances ................................................................... 6

3.2.2 New Drug Products ....................................................................... 7

3.3 Specific Tests / Criteria ................................................................................ 8

3.3.1 New Drug Substances ................................................................... 8

3.3.2 New Drug Products ..................................................................... 10

4. GLOSSARY ........................................................................................................... 18

5. REFERENCES ...................................................................................................... 20

6. ATTACHMENTS .................................................................................................. 21

1

SPECIFICATIONS: TEST PROCEDURES AND ACCEPTANCE CRITERIA

FOR NEW DRUG SUBSTANCES AND NEW DRUG PRODUCTS:

CHEMICAL SUBSTANCES

1. INTRODUCTION

1.1 Objective of the Guideline

This guideline is intended to assist to the extent possible, in the establishment of a

single set of global specifications for new drug substances and new drug products. It

provides guidance on the setting and justification of acceptance criteria and the

selection of test procedures for new drug substances of synthetic chemical origin, and

new drug products produced from them, which have not been registered previously in

the United States, the European Union, or Japan.

1.2 Background

A specification is defined as a list of tests, references to analytical procedures, and

appropriate acceptance criteria, which are numerical limits, ranges, or other criteria

for the tests described. It establishes the set of criteria to which a drug substance or

drug product should conform to be considered acceptable for its intended use.

"Conformance to specifications" means that the drug substance and / or drug product,

when tested according to the listed analytical procedures, will meet the listed

acceptance criteria. Specifications are critical quality standards that are proposed

and justified by the manufacturer and approved by regulatory authorities as

conditions of approval.

Specifications are one part of a total control strategy for the drug substance and drug

product designed to ensure product quality and consistency. Other parts of this

strategy include thorough product characterization during development, upon which

specifications are based, and adherence to Good Manufacturing Practices; e.g.,

suitable facilities, a validated manufacturing process, validated test procedure, raw

material testing, in-process testing, stability testing, etc.

Specifications are chosen to confirm the quality of the drug substance and drug

product rather than to establish full characterization, and should focus on those

characteristics found to be useful in ensuring the safety and efficacy of the drug

substance and drug product.

1.3 Scope of the Guideline

The quality of drug substances and drug products is determined by their design,

development, in-process controls, GMP controls, and process validation, and by

specifications applied to them throughout development and manufacture. This

guideline addresses specifications, i.e., those tests, procedures, and acceptance

criteria which play a major role in assuring the quality of the new drug substance

and new drug product at release and during shelf life. Specifications are an important

component of quality assurance, but are not its only component. All of the

considerations listed above are necessary to ensure consistent production of drug

substances and drug products of high quality.

This guideline addresses only the marketing approval of new drug products

(including combination products) and, where applicable, new drug substances; it does

not address drug substances or drug products during the clinical research stages of

drug development. This guideline may be applicable to synthetic and semi-synthetic

antibiotics and synthetic peptides of low molecular weight; however, it is not

Specifications: New Chemical Drug Substances and Products

2

sufficient to adequately describe specifications of higher molecular weight peptides

and polypeptides, and biotechnological/biological products. The ICH Guideline

Specifications: Test Procedures and Acceptance Criteria for

Biotechnological/Biological Products addresses guideline specifications, tests and

procedures for biotechnological/biological products. Radiopharmaceuticals, products

of fermentation, oligonucleotides, herbal products and crude products of animal or

plant origin are similarly not covered.

Guidance is provided with regard to acceptance criteria which should be established

for all new drug substances and new drug products, i.e. universal acceptance criteria,

and those that are considered specific to individual drug substances and / or dosage

forms. This guideline should not be considered all encompassing. New analytical

technologies, and modifications to existing technology, are continually being

developed. Such technologies should be used when justified.

Dosage forms addressed in this guideline include solid oral dosage forms, liquid oral

dosage forms, and parenterals (small and large volume). This is not meant to be an

all-inclusive list, or to limit the number of dosage forms to which this guideline

applies. The dosage forms presented serve as models, which may be applicable to

other dosage forms which have not been discussed. The extended application of the

concepts in this guideline to other dosage forms, e.g., to inhalation dosage forms

(powders, solutions, etc.), to topical formulations (creams, ointments, gels), and to

transdermal systems, is encouraged.

2. GENERAL CONCEPTS

The following concepts are important in the development and setting of harmonized

specifications. They are not universally applicable, but each should be considered in

particular circumstances. This guideline presents a brief definition of each concept

and an indication of the circumstances under which it may be applicable. Generally,

proposals to implement these concepts should be justified by the applicant and

approved by the appropriate regulatory authority before being put into effect.

2.1 Periodic or Skip Testing

Periodic or skip testing is the performance of specified tests at release on pre-selected

batches and / or at predetermined intervals, rather than on a batch-to-batch basis

with the understanding that those batches not being tested still must meet all

acceptance criteria established for that product. This represents a less than full

schedule of testing and should therefore be justified and presented to and approved

by the regulatory authority prior to implementation. This concept may be applicable

to, for example, residual solvents and microbiological testing, for solid oral dosage

forms. It is recognized that only limited data may be available at the time of

submission of an application (see section 2.5). This concept should therefore generally

be implemented post-approval. When tested, any failure to meet acceptance criteria

established for the periodic test should be handled by proper notification of the

appropriate regulatory authority(ies). If these data demonstrate a need to restore

routine testing, then batch by batch release testing should be reinstated.

2.2 Release vs. Shelf-life Acceptance Criteria

The concept of different acceptance criteria for release vs. shelf-life specifications

applies to drug products only; it pertains to the establishment of more restrictive

criteria for the release of a drug product than are applied to the shelf-life. Examples

where this may be applicable include assay and impurity (degradation product)

levels. In Japan and the United States, this concept may only be applicable to in-

house criteria, and not to the regulatory release criteria. Thus, in these regions, the

Specifications: New Chemical Drug Substances and Products

3

regulatory acceptance criteria are the same from release throughout shelf-life;

however, an applicant may choose to have tighter in-house limits at the time of

release to provide increased assurance to the applicant that the product will remain

within the regulatory acceptance criterion throughout its shelf-life. In the European

Union there is a regulatory requirement for distinct specifications for release and for

shelf-life where different.

2.3 In-process Tests

In-process tests, as presented in this guideline, are tests which may be performed

during the manufacture of either the drug substance or drug product, rather than as

part of the formal battery of tests which are conducted prior to release.

In-process tests which are only used for the purpose of adjusting process parameters

within an operating range, e.g., hardness and friability of tablet cores which will be

coated and individual tablet weights, are not included in the specification.

Certain tests conducted during the manufacturing process, where the acceptance

criterion is identical to or tighter than the release requirement, (e.g., pH of a

solution) may be sufficient to satisfy specification requirements when the test is

included in the specification. However, this approach should be validated to show

that test results or product performance characteristics do not change from the in-

process stage to finished product.

2.4 Design and Development Considerations

The experience and data accumulated during the development of a new drug

substance or product should form the basis for the setting of specifications. It may be

possible to propose excluding or replacing certain tests on this basis. Some examples

are:

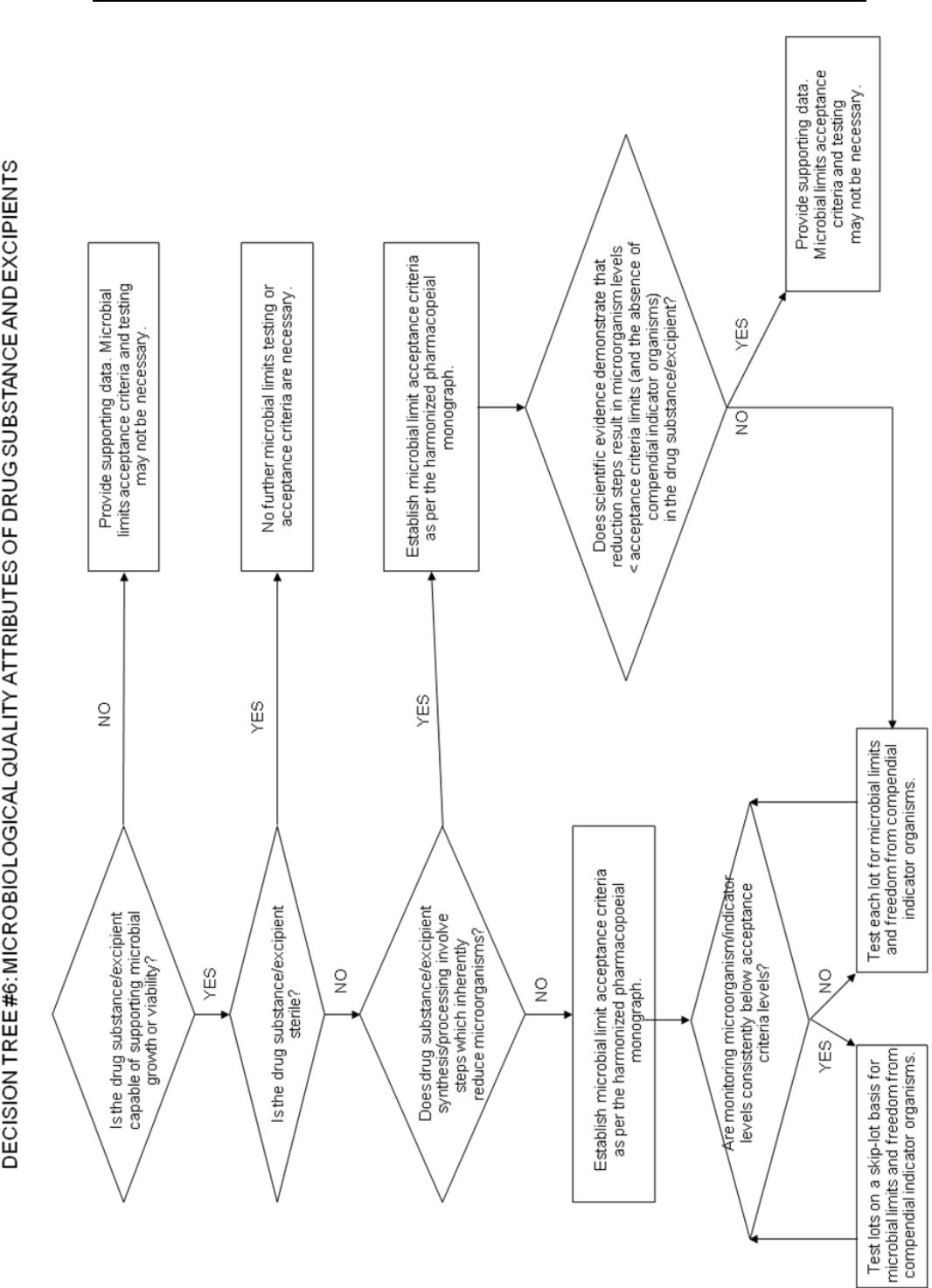

microbiological testing for drug substances and solid dosage forms which have

been shown during development not to support microbial viability or growth

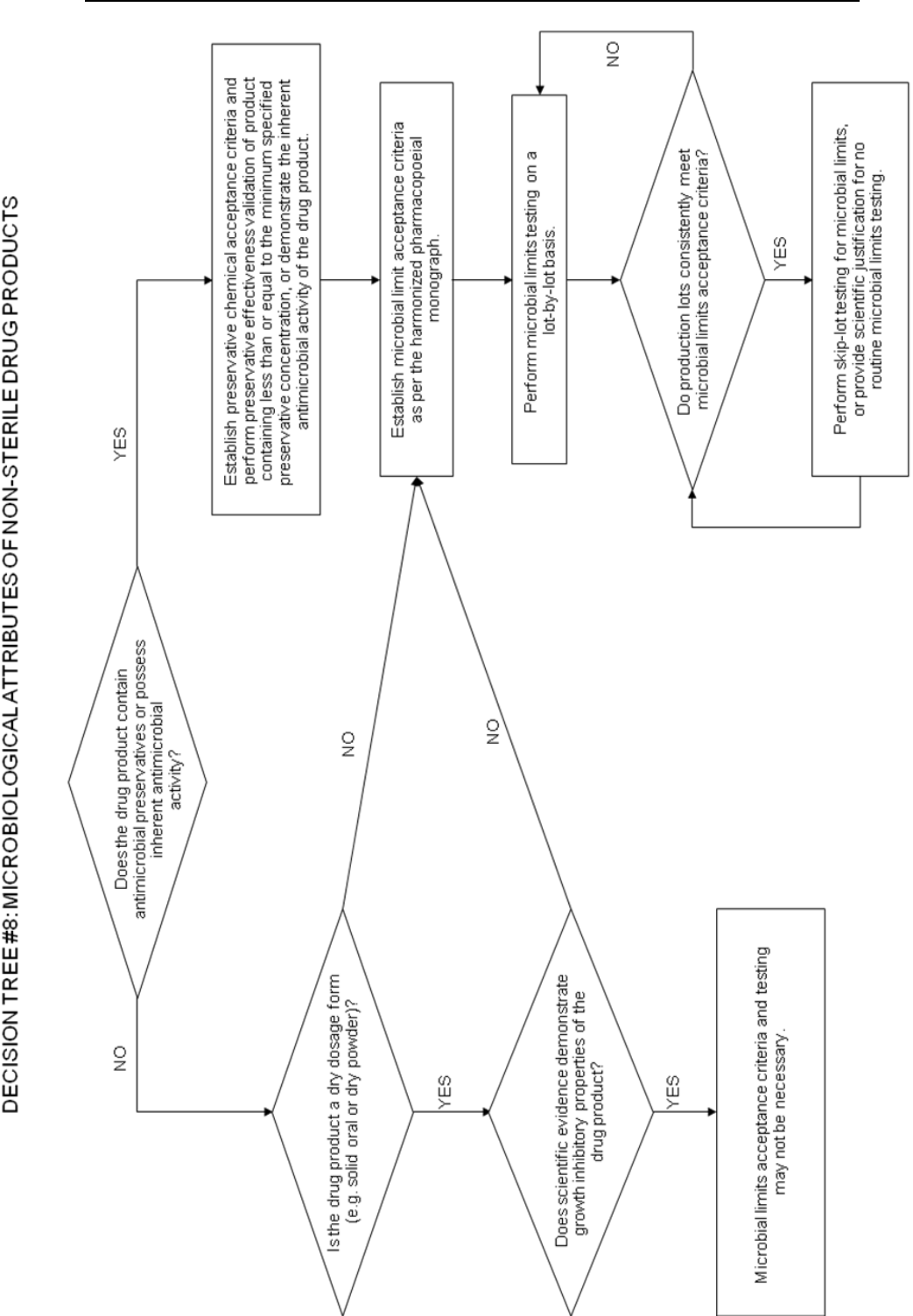

(see Decision Trees #6 and #8);

extractables from product containers where it has been reproducibly shown

that either no extractables are found in the drug product or the levels meet

accepted standards for safety;

particle size testing may fall into this category, may be performed as an in-

process test, or may be performed as a release test, depending on its relevance

to product performance;

dissolution testing for immediate release solid oral drug products made from

highly water soluble drug substances may be replaced by disintegration

testing, if these products have been demonstrated during development to

have consistently rapid drug release characteristics (see Decision Trees #7(1)

through #7(2)).

2.5 Limited Data Available at Filing

It is recognized that only a limited amount of data may be available at the time of

filing, which can influence the process of setting acceptance criteria. As a result it

may be necessary to propose revised acceptance criteria as additional experience is

gained with the manufacture of a particular drug substance or drug product

(example: acceptance limits for a specific impurity). The basis for the acceptance

criteria at the time of filing should necessarily focus on safety and efficacy.

When only limited data are available, the initially approved tests and acceptance

criteria should be reviewed as more information is collected, with a view towards

Specifications: New Chemical Drug Substances and Products

4

possible modification. This could involve loosening, as well as tightening, acceptance

criteria as appropriate.

2.6 Parametric Release

Parametric release can be used as an operational alternative to routine release

testing for the drug product in certain cases when approved by the regulatory

authority. Sterility testing for terminally sterilized drug products is one example. In

this case, the release of each batch is based on satisfactory results from monitoring

specific parameters, e.g., temperature, pressure, and time during the terminal

sterilization phase(s) of drug product manufacturing. These parameters can generally

be more accurately controlled and measured, so that they are more reliable in

predicting sterility assurance than is end-product sterility testing. Appropriate

laboratory tests (e.g., chemical or physical indicator) may be included in the

parametric release program. It is important to note that the sterilization process

should be adequately validated before parametric release is proposed and

maintenance of a validated state should be demonstrated by revalidation at

established intervals. When parametric release is performed, the attribute which is

indirectly controlled (e.g., sterility), together with a reference to the associated test

procedure, still should be included in the specifications.

2.7 Alternative Procedures

Alternative procedures are those which may be used to measure an attribute when

such procedures control the quality of the drug substance or drug product to an

extent that is comparable or superior to the official procedure. Example: for tablets

that have been shown not to degrade during manufacture, it may be permissible to

use a spectrophotometric procedure for release as opposed to the official procedure,

which is chromatographic. However, the chromatographic procedure should still be

used to demonstrate compliance with the acceptance criteria during the shelf-life of

the product.

2.8 Pharmacopoeial Tests and Acceptance Criteria

References to certain procedures are found in pharmacopoeias in each region.

Wherever they are appropriate, pharmacopoeial procedures should be utilized.

Whereas differences in pharmacopoeial procedures and/or acceptance criteria have

existed among the regions, a harmonized specification is possible only if the

procedures and acceptance criteria defined are acceptable to regulatory authorities in

all regions.

The full utility of this Guideline is dependent on the successful completion of

harmonization of pharmacopoeial procedures for several attributes commonly

considered in the specification for new drug substances or new drug products. The

Pharmacopoeial Discussion Group (PDG) of the European Pharmacopoeia, the

Japanese Pharmacopoeia, and the United States Pharmacopeia has expressed a

commitment to achieving harmonization of the procedures in a timely fashion.

Where harmonization has been achieved, an appropriate reference to the harmonized

procedure and acceptance criteria is considered acceptable for a specification in all

three regions. For example, after harmonization sterility data generated using the

JP procedure, as well as the JP procedure itself and its acceptance criteria, are

considered acceptable for registration in all three regions. To signify the harmonized

status of these procedures, the pharmacopoeias have agreed to include a statement in

their respective texts which indicates that the procedures and acceptance criteria

from all three pharmacopoeias are considered equivalent and are, therefore,

interchangeable.

Specifications: New Chemical Drug Substances and Products

5

Since the overall value of this Guideline is linked to the extent of harmonization of

the analytical procedures and acceptance criteria of the pharmacopoeias, it is agreed

by the members of the Q6A expert working group that none of the three

pharmacopoeias should change a harmonized monograph unilaterally. According to

the PDG procedure for the revision of harmonized monographs and chapters, “no

pharmacopoeia shall revise unilaterally any monograph or chapter after sign-off or

after publication.”

2.9 Evolving Technologies

New analytical technologies, and modifications to existing technology, are continually

being developed. Such technologies should be used when they are considered to offer

additional assurance of quality, or are otherwise justified.

2.10 Impact of Drug Substance on Drug Product Specifications

In general, it should not be necessary to test the drug product for quality attributes

uniquely associated with the drug substance. Example: it is normally not considered

necessary to test the drug product for synthesis impurities which are controlled in the

drug substance and are not degradation products. Refer to the ICH Guideline

Impurities in New Drug Products for detailed information.

2.11 Reference Standard

A reference standard, or reference material, is a substance prepared for use as the

standard in an assay, identification, or purity test. It should have a quality

appropriate to its use. It is often characterized and evaluated for its intended purpose

by additional procedures other than those used in routine testing. For new drug

substance reference standards intended for use in assays, the impurities should be

adequately identified and / or controlled, and purity should be measured by a

quantitative procedure.

3. GUIDELINES

3.1 Specifications: Definition and Justification

3.1.1 Definition of Specifications

A specification is defined as a list of tests, references to analytical procedures, and

appropriate acceptance criteria which are numerical limits, ranges, or other criteria

for the tests described. It establishes the set of criteria to which a new drug

substance or new drug product should conform to be considered acceptable for its

intended use. "Conformance to specifications" means that the drug substance and / or

drug product, when tested according to the listed analytical procedures, will meet the

listed acceptance criteria. Specifications are critical quality standards that are

proposed and justified by the manufacturer and approved by regulatory authorities

as conditions of approval.

It is possible that, in addition to release tests, a specification may list in-process tests

as defined in 2.3, periodic (skip) tests, and other tests which are not always

conducted on a batch-by-batch basis. In such cases the applicant should specify which

tests are routinely conducted batch-by-batch, and which tests are not, with an

indication and justification of the actual testing frequency. In this situation, the drug

substance and / or drug product should meet the acceptance criteria if tested.

It should be noted that changes in the specification after approval of the application

may need prior approval by the regulatory authority.

Specifications: New Chemical Drug Substances and Products

6

3.1.2 Justification of Specifications

When a specification is first proposed, justification should be presented for each

procedure and each acceptance criterion included. The justification should refer to

relevant development data, pharmacopoeial standards, test data for drug substances

and drug products used in toxicology and clinical studies, and results from

accelerated and long term stability studies, as appropriate. Additionally, a reasonable

range of expected analytical and manufacturing variability should be considered. It is

important to consider all of this information.

Approaches other than those set forth in this guideline may be applicable and

acceptable. The applicant should justify alternative approaches. Such justification

should be based on data derived from the new drug substance synthesis and/or the

new drug product manufacturing process. This justification may consider theoretical

tolerances for a given procedure or acceptance criterion, but the actual results

obtained should form the primary basis for whatever approach is taken.

Test results from stability and scale-up / validation batches, with emphasis on the

primary stability batches, should be considered in setting and justifying

specifications. If multiple manufacturing sites are planned, it may be valuable to

consider data from these sites in establishing the initial tests and acceptance criteria.

This is particularly true when there is limited initial experience with the

manufacture of the drug substance or drug product at any particular site. If data

from a single representative manufacturing site are used in setting tests and

acceptance criteria, product manufactured at all sites should still comply with these

criteria.

Presentation of test results in graphic format may be helpful in justifying individual

acceptance criteria, particularly for assay values and impurity levels. Data from

development work should be included in such a presentation, along with stability

data available for new drug substance or new drug product batches manufactured by

the proposed commercial processes. Justification for proposing exclusion of a test

from the specification should be based on development data and on process validation

data (where appropriate).

3.2 Universal Tests / Criteria

Implementation of the recommendations in the following section should take into

account the ICH Guidelines “Text on Validation of Analytical Procedures” and

“Validation of Analytical Procedures: Methodology”.

3.2.1 New Drug Substances

The following tests and acceptance criteria are considered generally applicable to all

new drug substances.

a) Description: a qualitative statement about the state (e.g. solid, liquid) and color of

the new drug substance. If any of these characteristics change during storage, this

change should be investigated and appropriate action taken.

b) Identification: identification testing should optimally be able to discriminate

between compounds of closely related structure which are likely to be present.

Identification tests should be specific for the new drug substance, e.g., infrared

spectroscopy. Identification solely by a single chromatographic retention time, for

example, is not regarded as being specific. However, the use of two chromatographic

procedures, where the separation is based on different principles or a combination of

tests into a single procedure, such as HPLC/UV diode array, HPLC/MS, or GC/MS is

generally acceptable. If the new drug substance is a salt, identification testing should

Specifications: New Chemical Drug Substances and Products

7

be specific for the individual ions. An identification test that is specific for the salt

itself should suffice.

New drug substances which are optically active may also need specific identification

testing or performance of a chiral assay. Please refer to 3.3.1.d) in this Guideline for

further discussion of this topic.

c) Assay: A specific, stability-indicating procedure should be included to determine

the content of the new drug substance. In many cases it is possible to employ the

same procedure (e.g., HPLC) for both assay of the new drug substance and

quantitation of impurities.

In cases where use of a non-specific assay is justified, other supporting analytical

procedures should be used to achieve overall specificity. For example, where titration

is adopted to assay the drug substance, the combination of the assay and a suitable

test for impurities should be used.

d) Impurities: Organic and inorganic impurities and residual solvents are included in

this category. Refer to the ICH Guidelines Impurities in New Drug Substances and

Residual Solvents in Pharmaceuticals for detailed information.

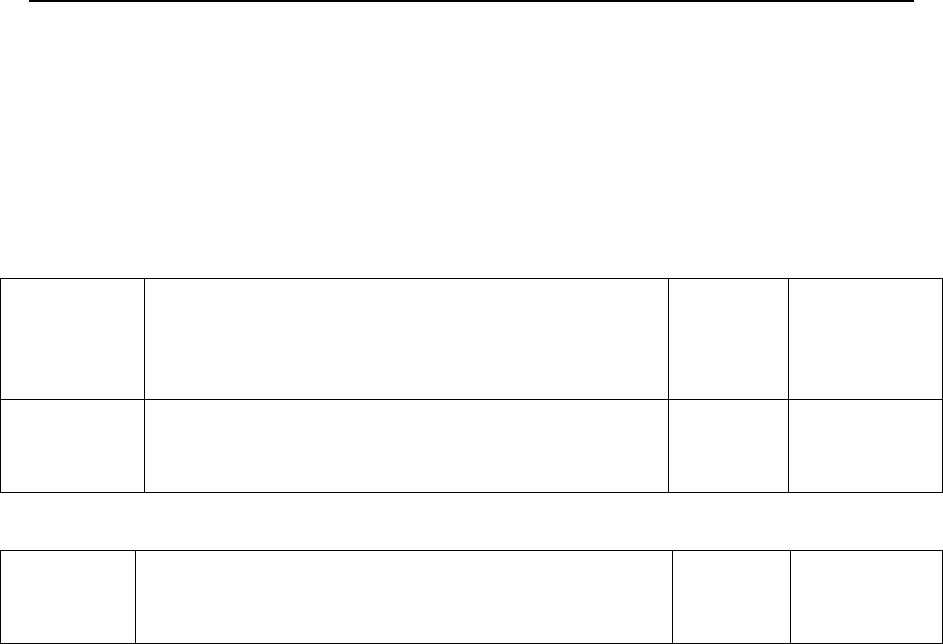

Decision tree #1 addresses the extrapolation of meaningful limits on impurities from

the body of data generated during development. At the time of filing it is unlikely

that sufficient data will be available to assess process consistency. Therefore it is

considered inappropriate to establish acceptance criteria which tightly encompass the

batch data at the time of filing. (see section 2.5)

3.2.2 New Drug Products

The following tests and acceptance criteria are considered generally applicable to all

new drug products:

a) Description: A qualitative description of the dosage form should be provided (e.g.,

size, shape, and color). If any of these characteristics change during manufacture or

storage, this change should be investigated and appropriate action taken. The

acceptance criteria should include the final acceptable appearance. If color changes

during storage, a quantitative procedure may be appropriate.

b) Identification: Identification testing should establish the identity of the new drug

substance(s) in the new drug product and should be able to discriminate between

compounds of closely related structure which are likely to be present. Identity tests

should be specific for the new drug substance, e.g., infrared spectroscopy.

Identification solely by a single chromatographic retention time, for example, is not

regarded as being specific. However, the use of two chromatographic procedures,

where the separation is based on different principles, or combination of tests into a

single procedure, such as HPLC/UV diode array, HPLC/MS, or GC/MS, is generally

acceptable.

c) Assay: A specific, stability-indicating assay to determine strength (content) should

be included for all new drug products. In many cases it is possible to employ the same

procedure (e.g., HPLC) for both assay of the new drug substance and quantitation of

impurities. Results of content uniformity testing for new drug products can be used

for quantitation of drug product strength, if the methods used for content uniformity

are also appropriate as assays.

In cases where use of a non-specific assay is justified, other supporting analytical

procedures should be used to achieve overall specificity. For example, where titration

is adopted to assay the drug substance for release, the combination of the assay and a

Specifications: New Chemical Drug Substances and Products

8

suitable test for impurities can be used. A specific procedure should be used when

there is evidence of excipient interference with the non-specific assay.

d) Impurities: Organic and inorganic impurities (degradation products) and residual

solvents are included in this category. Refer to the ICH Guidelines Impurities in

New Drug Products and Residual Solvents for detailed information.

Organic impurities arising from degradation of the new drug substance and

impurities that arise during the manufacturing process for the drug product should

be monitored in the new drug product. Acceptance limits should be stated for

individual specified degradation products, which may include both identified and

unidentified degradation products as appropriate, and total degradation products.

Process impurities from the new drug substance synthesis are normally controlled

during drug substance testing, and therefore are not included in the total impurities

limit. However, when a synthesis impurity is also a degradation product, its level

should be monitored and included in the total degradation product limit. When it has

been conclusively demonstrated via appropriate analytical methodology, that the

drug substance does not degrade in the specific formulation, and under the specific

storage conditions proposed in the new drug application, degradation product testing

may be reduced or eliminated upon approval by the regulatory authorities.

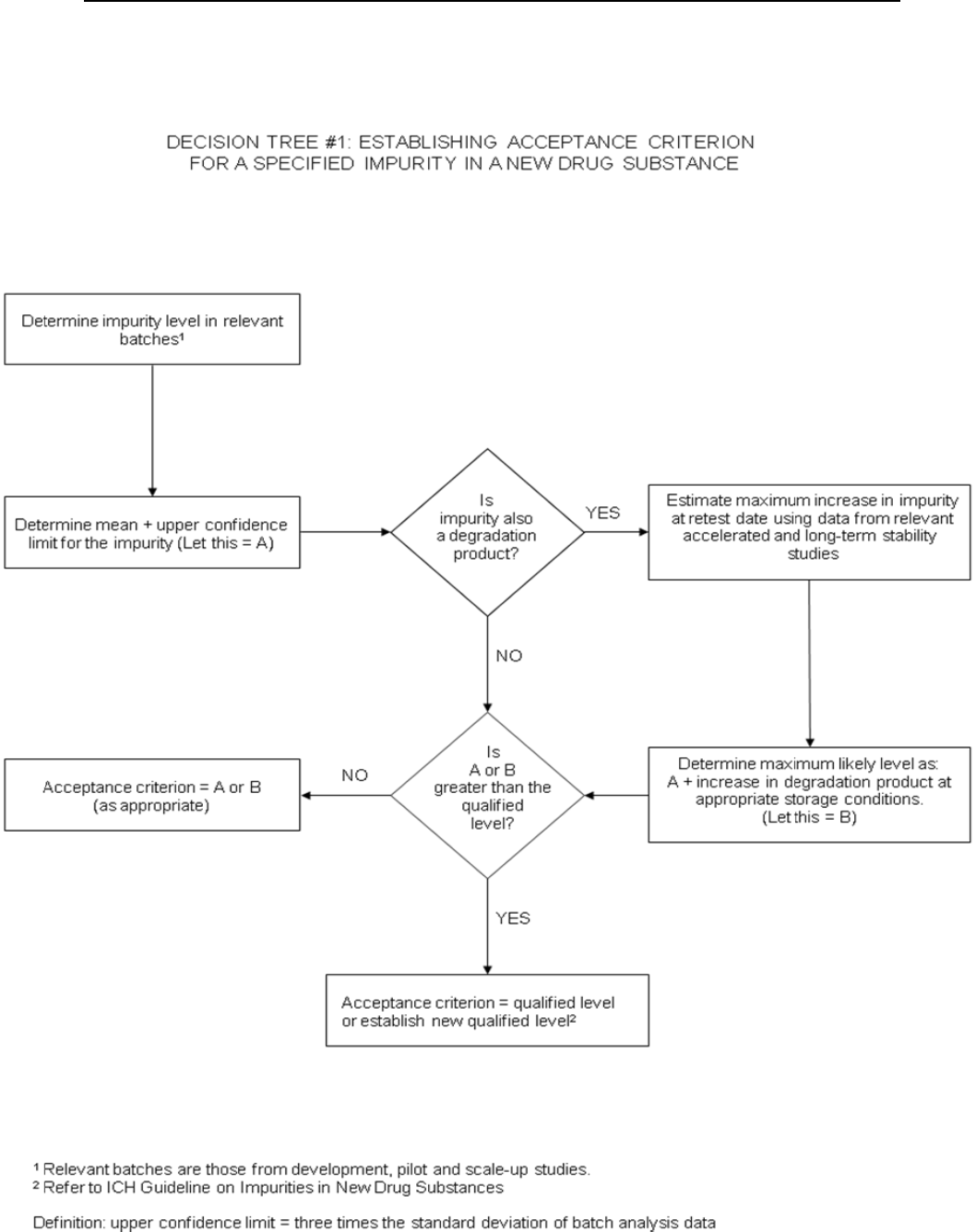

Decision tree #2 addresses the extrapolation of meaningful limits on degradation

products from the body of data generated during development. At the time of filing it

is unlikely that sufficient data will be available to assess process consistency.

Therefore it is considered inappropriate to establish acceptance criteria which tightly

encompass the batch data at the time of filing. (see section 2.5)

3.3 Specific Tests / Criteria

In addition to the universal tests listed above, the following tests may be considered

on a case by case basis for drug substances and/or drug products. Individual

tests/criteria should be included in the specification when the tests have an impact on

the quality of the drug substance and drug product for batch control. Tests other than

those listed below may be needed in particular situations or as new information

becomes available.

3.3.1 New Drug Substances

a) Physicochemical properties: These are properties such as pH of an aqueous

solution, melting point / range, and refractive index. The procedures used for the

measurement of these properties are usually unique and do not need much

elaboration, e.g., capillary melting point, Abbé refractometry. The tests performed in

this category should be determined by the physical nature of the new drug substance

and by its intended use.

b) Particle size: For some new drug substances intended for use in solid or suspension

drug products, particle size can have a significant effect on dissolution rates,

bioavailability, and / or stability. In such instances, testing for particle size

distribution should be carried out using an appropriate procedure, and acceptance

criteria should be provided.

Decision tree #3 provides additional guidance on when particle size testing should be

considered.

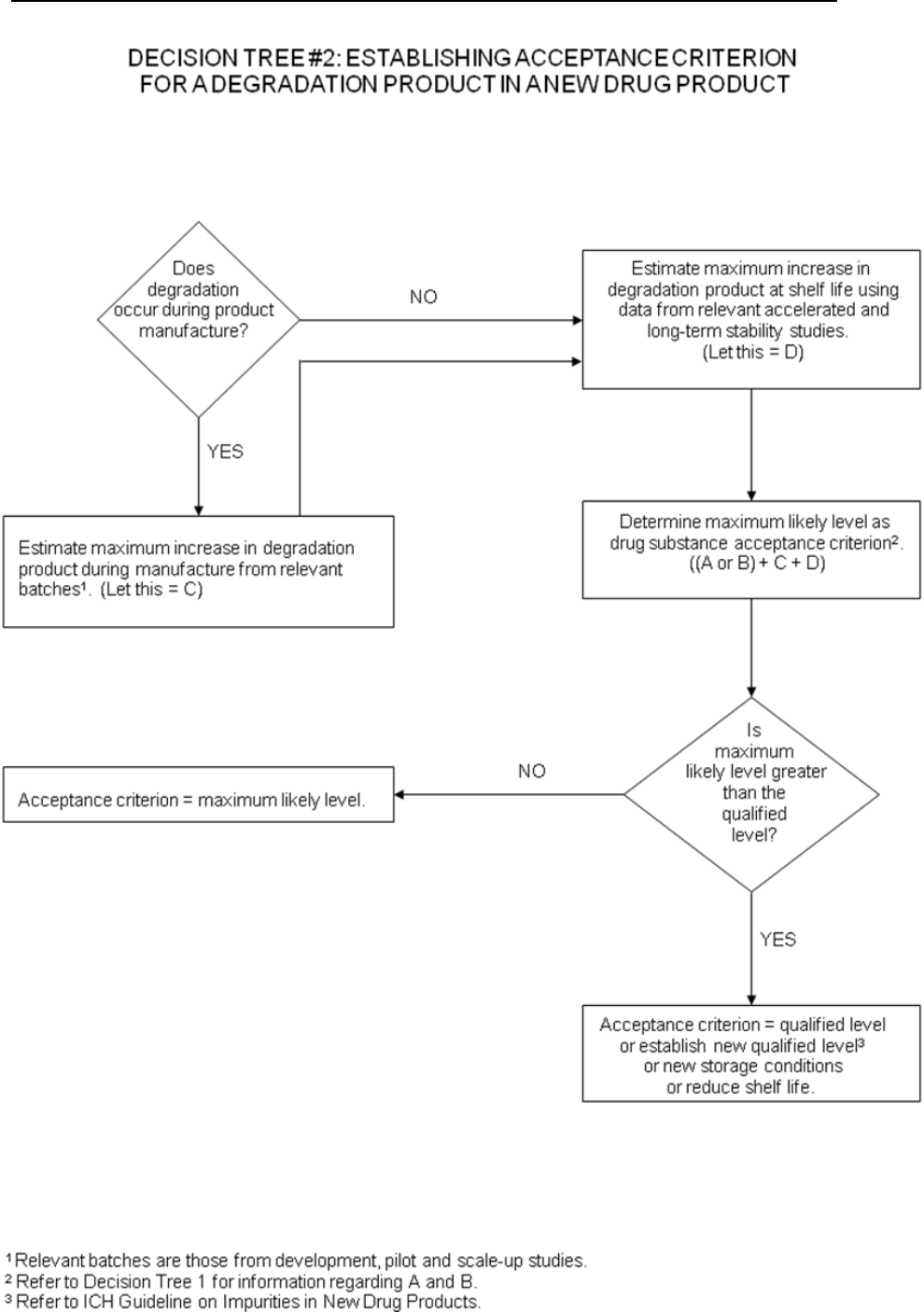

c) Polymorphic forms: Some new drug substances exist in different crystalline forms

which differ in their physical properties. Polymorphism may also include solvation or

hydration products (also known as pseudopolymorphs) and amorphous forms.

Differences in these forms could, in some cases, affect the quality or performance of

Specifications: New Chemical Drug Substances and Products

9

the new drug products. In cases where differences exist which have been shown to

affect drug product performance, bioavailability or stability, then the appropriate

solid state should be specified.

Physicochemical measurements and techniques are commonly used to determine

whether multiple forms exist. Examples of these procedures are: melting point

(including hot-stage microscopy), solid state IR, X-ray powder diffraction, thermal

analysis procedures (like DSC, TGA and DTA), Raman spectroscopy, optical

microscopy, and solid state NMR.

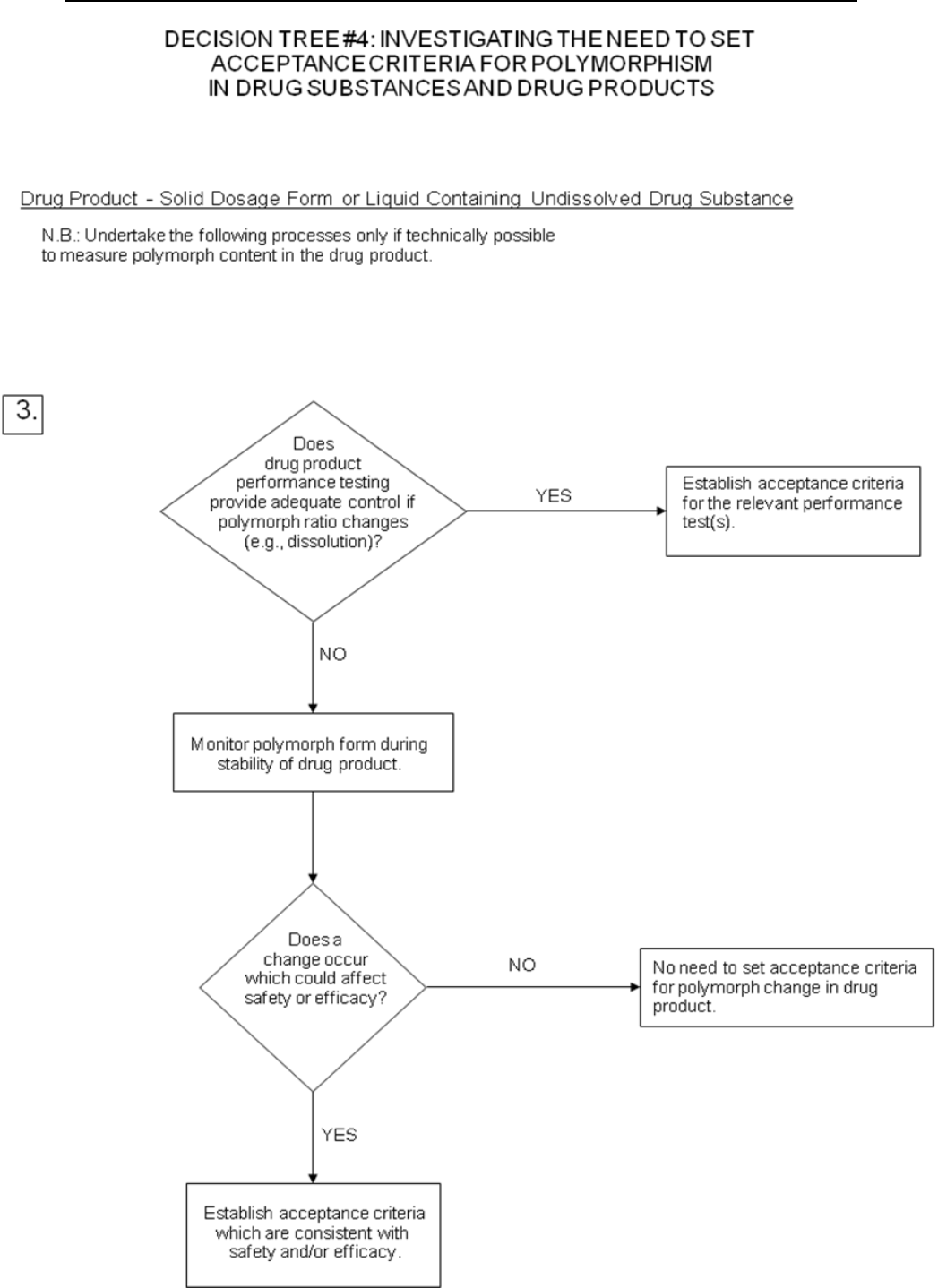

Decision trees #4(1) through 4(3) provide additional guidance on when, and how,

polymorphic forms should be monitored and controlled.

Note: These decision trees should be followed sequentially. Trees 1 and 2 consider

whether polymorphism is exhibited by the drug substance, and whether the different

polymorphic forms can affect performance of the drug product. Tree 3 should only be

applied when polymorphism has been demonstrated for the drug substance, and

shown to affect these properties. Tree 3 considers the potential for change in

polymorphic forms in the drug product, and whether such a change has any effect on

product performance.

It is generally technically very difficult to measure polymorphic changes in drug

products. A surrogate test (e.g., dissolution) (see Decision tree 4(3)) can generally be

used to monitor product performance, and polymorph content should only be used as

a test and acceptance criterion of last resort.

d) Tests for chiral new drug substances: Where a new drug substance is

predominantly one enantiomer, the opposite enantiomer is excluded from the

qualification and identification thresholds given in the ICH Guidelines on Impurities

in New Drug Substances and Impurities in New Drug Products because of practical

difficulties in quantifying it at those levels. However, that impurity in the chiral new

drug substance and the resulting new drug product(s) should otherwise be treated

according to the principles established in those Guidelines.

Decision tree #5 summarizes when and if chiral identity tests, impurity tests, and

assays may be needed for both new drug substances and new drug products,

according to the following concepts:

Drug Substance: Impurities. For chiral drug substances which are developed as a

single enantiomer, control of the other enantiomer should be considered in the

same manner as for other impurities. However, technical limitations may

preclude the same limits of quantification or qualification from being applied.

Assurance of control also could be given by appropriate testing of a starting

material or intermediate, with suitable justification.

Assay. An enantioselective determination of the drug substance should be part of

the specification. It is considered acceptable for this to be achieved either through

use of a chiral assay procedure or by the combination of an achiral assay together

with appropriate methods of controlling the enantiomeric impurity.

Identity. For a drug substance developed as a single enantiomer, the identity

test(s) should be capable of distinguishing both enantiomers and the racemic

mixture. For a racemic drug substance, there are generally two situations where

a stereospecific identity test is appropriate for release/acceptance testing: 1)

where there is a significant possibility that the enantiomer might be substituted

for the racemate, or 2) when there is evidence that preferential crystallization

may lead to unintentional production of a non-racemic mixture.

Specifications: New Chemical Drug Substances and Products

10

Drug Product: Degradation products. Control of the other enantiomer in a drug

product is considered necessary unless racemization has been shown to be

insignificant during manufacture of the dosage form, and on storage.

Assay: An achiral assay may be sufficient where racemization has been shown to

be insignificant during manufacture of the dosage form, and on storage.

Otherwise a chiral assay should be used, or alternatively, the combination of an

achiral assay plus a validated procedure to control the presence of the opposite

enantiomer may be used.

Identity: A stereospecific identity test is not generally needed in the drug product

release specification. When racemization is insignificant during manufacture of

the dosage form, and on storage, stereospecific identity testing is more

appropriately addressed as part of the drug substance specification. When

racemization in the dosage form is a concern, chiral assay or enantiomeric

impurity testing of the drug product will serve to verify identity.

e) Water content: This test is important in cases where the new drug substance is

known to be hygroscopic or degraded by moisture or when the drug substance is

known to be a stoichiometric hydrate. The acceptance criteria may be justified with

data on the effects of hydration or moisture absorption. In some cases, a Loss on

Drying procedure may be considered adequate; however, a detection procedure that is

specific for water (e.g., Karl Fischer titration) is preferred.

f) Inorganic impurities: The need for inclusion of tests and acceptance criteria for

inorganic impurities (e.g., catalysts) should be studied during development and based

on knowledge of the manufacturing process. Procedures and acceptance criteria for

sulfated ash / residue on ignition should follow pharmacopoeial precedents; other

inorganic impurities may be determined by other appropriate procedures, e.g., atomic

absorption spectroscopy.

g) Microbial limits: There may be a need to specify the total count of aerobic

microorganisms, the total count of yeasts and molds, and the absence of specific

objectionable bacteria (e.g., Staphylococcus aureus, Escherichia coli, Salmonella,

Pseudomonas aeruginosa). These should be suitably determined using

pharmacopoeial procedures. The type of microbial test(s) and acceptance criteria

should be based on the nature of the drug substance, method of manufacture, and the

intended use of the drug product. For example, sterility testing may be appropriate

for drug substances manufactured as sterile and endotoxin testing may be

appropriate for drug substances used to formulate an injectable drug product.

Decision tree #6 provides additional guidance on when microbial limits should be

included.

3.3.2 New Drug Products

Additional tests and acceptance criteria generally should be included for particular

new drug products. The following selection presents a representative sample of both

the drug products and the types of tests and acceptance criteria which may be

appropriate. The specific dosage forms addressed include solid oral drug products,

liquid oral drug products, and parenterals (small and large volume). Application of

the concepts in this guideline to other dosage forms is encouraged. Note that issues

related to optically active drug substances and to solid state considerations for drug

products are discussed in part 3.3.1. of this guideline.

3.3.2.1 The following tests are applicable to tablets (coated and uncoated) and hard

capsules. One or more of these tests may also be applicable to soft capsules and

granules.

Specifications: New Chemical Drug Substances and Products

11

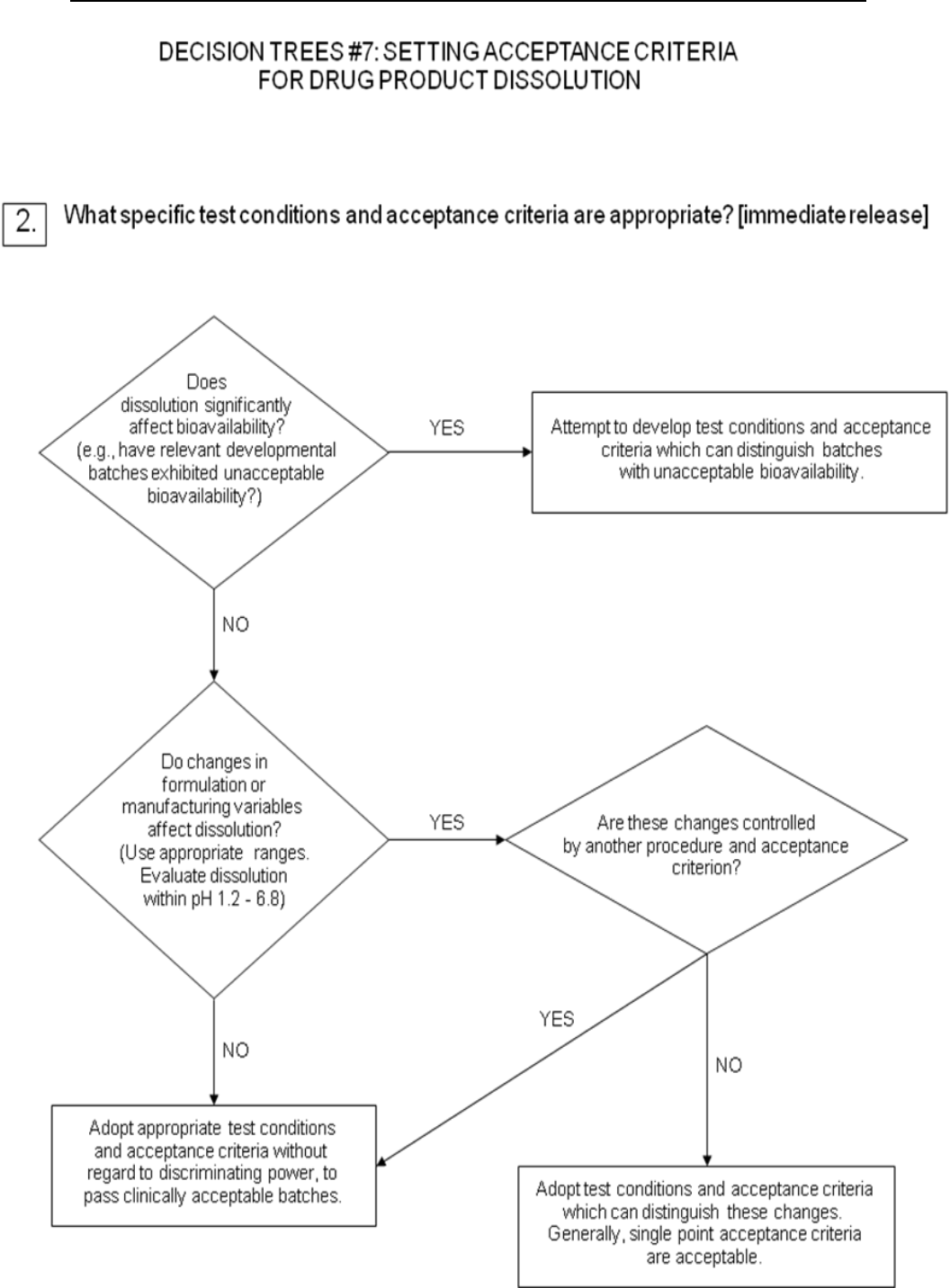

a) Dissolution: The specification for solid oral dosage forms normally includes a test

to measure release of drug substance from the drug product. Single-point

measurements are normally considered to be suitable for immediate-release dosage

forms. For modified-release dosage forms, appropriate test conditions and sampling

procedures should be established. For example, multiple time point sampling should

be performed for extended-release dosage forms, and two-stage testing (using

different media in succession or in parallel, as appropriate) may be appropriate for

delayed-release dosage forms. In these cases it is important to consider the

populations of individuals who will be taking the drug product (e.g., achlorhydric

elderly) when designing the tests and acceptance criteria. In some cases (see 3.3.2.1

b) Disintegration) dissolution testing may be replaced by disintegration testing (see

Decision Tree #7 (1)).

For immediate-release drug products where changes in dissolution rate have been

demonstrated to significantly affect bioavailability, it is desirable to develop test

conditions which can distinguish batches with unacceptable bioavailability. If

changes in formulation or process variables significantly affect dissolution and such

changes are not controlled by another aspect of the specification, it may also be

appropriate to adopt dissolution test conditions which can distinguish these changes

(see Decision Tree #7(2)).

Where dissolution significantly affects bioavailability, the acceptance criteria should

be set to reject batches with unacceptable bioavailability. Otherwise, test conditions

and acceptance criteria should be established which pass clinically acceptable batches

(see Decision Tree #7(2)).

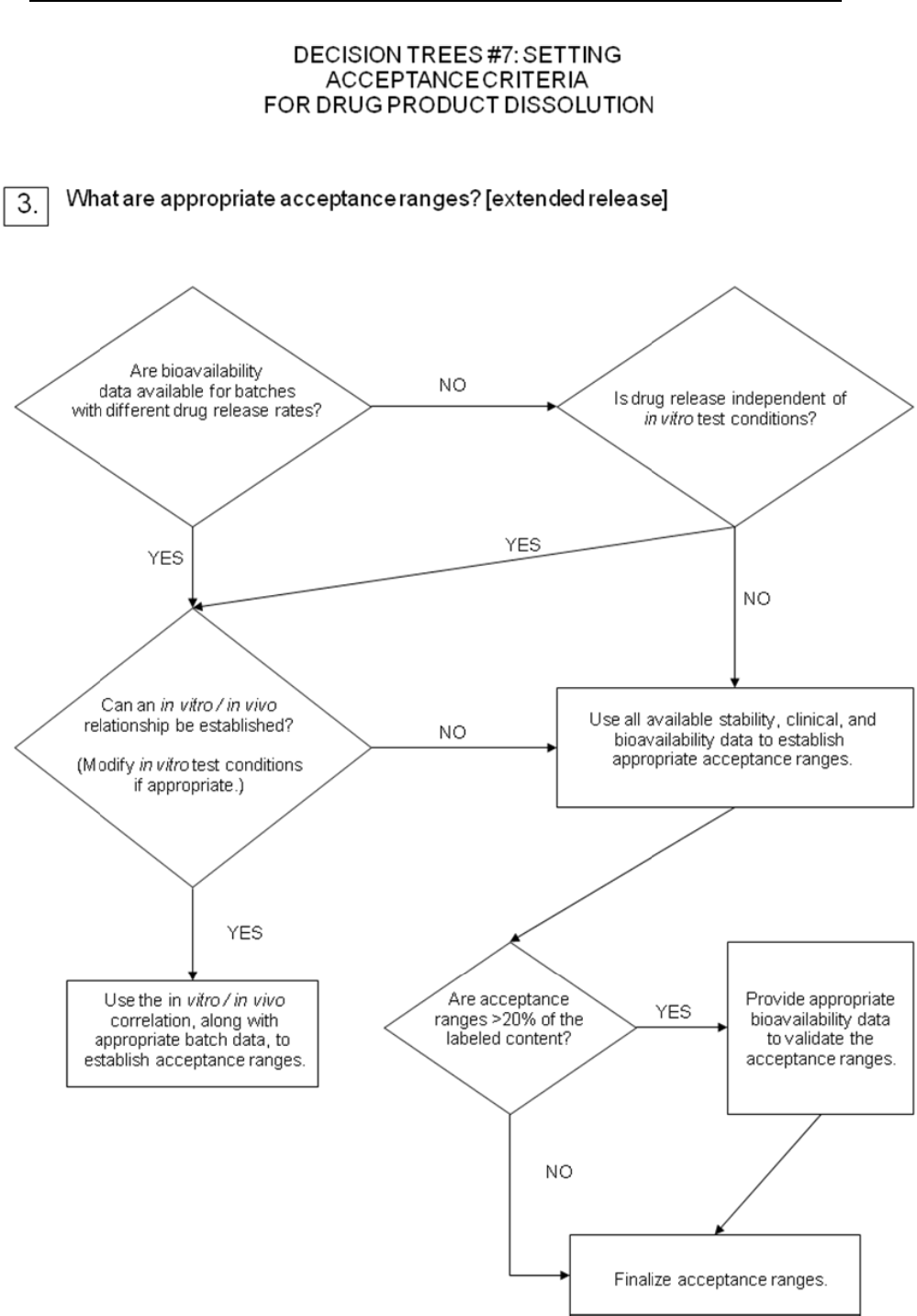

For extended-release drug products, in vitro / in vivo correlation may be used to

establish acceptance criteria when human bioavailability data are available for

formulations exhibiting different release rates. Where such data are not available,

and drug release cannot be shown to be independent of in vitro test conditions, then

acceptance criteria should be established on the basis of available batch data.

Normally, the permitted variability in mean release rate at any given time point

should not exceed a total numerical difference of +/-10% of the labeled content of drug

substance (i.e., a total variability of 20%: a requirement of 50 +/- 10% thus means an

acceptable range from 40% to 60%), unless a wider range is supported by a

bioequivalency study (see Decision Tree #7(3)).

b) Disintegration: For rapidly dissolving (dissolution >80% in 15 minutes at pH 1.2,

4.0 and 6.8) products containing drugs which are highly soluble throughout the

physiological range (dose/solubility volume < 250 mL from pH 1.2 to 6.8),

disintegration may be substituted for dissolution. Disintegration testing is most

appropriate when a relationship to dissolution has been established or when

disintegration is shown to be more discriminating than dissolution. In such cases

dissolution testing may not be necessary. It is expected that development information

will be provided to support the robustness of the formulation and manufacturing

process with respect to the selection of dissolution vs. disintegration testing (see

Decision Tree #7(1)).

c) Hardness/friability: It is normally appropriate to perform hardness and/or

friability testing as an in-process control (see section 2.3). Under these circumstances,

it is normally not necessary to include these attributes in the specification. If the

characteristics of hardness and friability have a critical impact on drug product

quality (e.g., chewable tablets), acceptance criteria should be included in the

specification.

Specifications: New Chemical Drug Substances and Products

12

d) Uniformity of dosage units: This term includes both the mass of the dosage form

and the content of the active substance in the dosage form; a pharmacopoeial

procedure should be used. In general, the specification should include one or the

other but not both. If appropriate, these tests may be performed in-process; the

acceptance criteria should be included in the specification. When weight variation is

applied for new drug products exceeding the threshold value to allow testing

uniformity by weight variation, applicants should verify during drug development

that the homogeneity of the product is adequate.

e) Water content: A test for water content should be included when appropriate. The

acceptance criteria may be justified with data on the effects of hydration or water

absorption on the drug product. In some cases, a Loss on Drying procedure may be

considered adequate; however, a detection procedure which is specific for water (e.g.,

Karl Fischer titration) is preferred.

f) Microbial limits: Microbial limit testing is seen as an attribute of Good

Manufacturing Practice, as well as of quality assurance. In general, it is advisable to

test the drug product unless its components are tested before manufacture and the

manufacturing process is known, through validation studies, not to carry a

significant risk of microbial contamination or proliferation. It should be noted that,

whereas this guideline does not directly address excipients, the principles discussed

here may be applicable to excipients as well as to new drug products. Skip testing

may be an appropriate approach in both cases where permissible. (See Decision Tree

#6 for microbial testing of excipients.)

Acceptance criteria should be set for the total count of aerobic microorganisms, the

total count of yeasts and molds, and the absence of specific objectionable bacteria

(e.g., Staphylococcus aureus, Escherichia coli, Salmonella, Pseudomonas aeruginosa).

These should be determined by suitable procedures, using pharmacopoeial

procedures, and at a sampling frequency or time point in manufacture which is

justified by data and experience. The type of microbial test(s) and acceptance criteria

should be based on the nature of the drug substance, method of manufacture, and the

intended use of the drug product. With acceptable scientific justification, it should be

possible to propose no microbial limit testing for solid oral dosage forms.

Decision tree #8 provides additional guidance on the use of microbial limits testing.

3.3.2.2 Oral liquids: One or more of the following specific tests will normally be

applicable to oral liquids and to powders intended for reconstitution as oral liquids.

a) Uniformity of dosage units: This term includes both the mass of the dosage form

and the content of the active substance in the dosage form; a pharmacopoeial

procedure should be used. In general, the specification should include one or the

other but not both. When weight variation is applied for new drug products

exceeding the threshold value to allow testing uniformity by weight variation,

applicants should verify during drug development that the homogeneity of the

product is adequate.

If appropriate, tests may be performed in-process; however, the acceptance criteria

should be included in the specification. This concept may be applied to both single-

dose and multiple-dose packages.

The dosage unit is considered to be the typical dose taken by the patient. If the actual

unit dose, as taken by the patient, is controlled, it may either be measured directly or

calculated, based on the total measured weight or volume of drug divided by the total

number of doses expected. If dispensing equipment (such as medicine droppers or

dropper tips for bottles) is an integral part of the packaging, this equipment should

Specifications: New Chemical Drug Substances and Products

13

be used to measure the dose. Otherwise, a standard volume measure should be used.

The dispensing equipment to be used is normally determined during development.

For powders for reconstitution, uniformity of mass testing is generally considered

acceptable.

b) pH: Acceptance criteria for pH should be provided where applicable and the

proposed range justified.

c) Microbial limits: Microbial limit testing is seen as an attribute of Good

Manufacturing Practice, as well as of quality assurance. In general, it is advisable to

test the drug product unless its components are tested before manufacture and the

manufacturing process is known, through validation studies, not to carry a

significant risk of microbial contamination or proliferation. It should be noted that,

whereas this Guideline does not directly address excipients, the principles discussed

here may be applicable to excipients as well as to new drug products. Skip testing

may be an appropriate approach in both cases where permissible. With acceptable

scientific justification, it may be possible to propose no microbial limit testing for

powders intended for reconstitution as oral liquids.

Acceptance criteria should be set for the total count of aerobic microorganisms, total

count of yeasts and molds, and the absence of specific objectionable bacteria (e.g.,

Staphylococcus aureus, Escherichia coli, Salmonella, Pseudomonas aeruginosa).

These should be determined by suitable procedures, using pharmacopoeial

procedures, and at a sampling frequency or time point in manufacture which is

justified by data and experience.

Decision tree #8 provides additional guidance on the use of microbial limits testing.

d) Antimicrobial preservative content: For oral liquids needing an antimicrobial

preservative, acceptance criteria for preservative content should be established.

Acceptance criteria for preservative content should be based upon the levels of

antimicrobial preservative necessary to maintain microbiological quality of the

product at all stages throughout its proposed usage and shelf-life. The lowest

specified concentration of antimicrobial preservative should be demonstrated to be

effective in controlling microorganisms by using a pharmacopoeial antimicrobial

preservative effectiveness test.

Testing for antimicrobial preservative content should normally be performed at

release. Under certain circumstances, in-process testing may suffice in lieu of release

testing. When antimicrobial preservative content testing is performed as an in-

process test, the acceptance criteria should remain part of the specification.

Antimicrobial preservative effectiveness should be demonstrated during

development, during scaleup, and throughout the shelf-life (e.g., in stability testing:

see the ICH Guideline, “Stability Testing of New Drug Substances and Products”),

although chemical testing for preservative content is the attribute normally included

in the specification.

e) Antioxidant preservative content: Release testing for antioxidant content should

normally be performed. Under certain circumstances, where justified by

developmental and stability data, shelf-life testing may be unnecessary, and in-

process testing may suffice in lieu of release testing where permitted. When

antioxidant content testing is performed as an in-process test, the acceptance criteria

should remain part of the specification. If only release testing is performed, this

decision should be reinvestigated whenever either the manufacturing procedure or

the container/closure system changes.

Specifications: New Chemical Drug Substances and Products

14

f) Extractables: Generally, where development and stability data show evidence that

extractables from the container/closure systems are consistently below levels that are

demonstrated to be acceptable and safe, elimination of this test can normally be

accepted. This should be reinvestigated if the container/closure system or

formulation changes.

Where data demonstrate the need, tests and acceptance criteria for extractables from

the container/closure system components (e.g., rubber stopper, cap liner, plastic

bottle, etc.) are considered appropriate for oral solutions packaged in non-glass

systems, or in glass containers with non-glass closures. The container/closure

components should be listed, and data collected for these components as early in the

development process as possible.

g) Alcohol content: Where it is declared quantitatively on the label in accordance with

pertinent regulations, the alcohol content should be specified. It may be assayed or

calculated.

h) Dissolution: In addition to the attributes recommended immediately above, it may

be appropriate (e.g., insoluble drug substance) to include dissolution testing and

acceptance criteria for oral suspensions and dry powder products for resuspension.

Dissolution testing should be performed at release. This test may be performed as an

in-process test when justified by product development data. The testing apparatus,

media, and conditions should be pharmacopoeial, if possible, or otherwise justified.

Dissolution procedures using either pharmacopoeial or non-pharmacopoeial

apparatus and conditions should be validated.

Single-point measurements are normally considered suitable for immediate-release

dosage forms. Multiple-point sampling, at appropriate intervals, should be performed

for modified-release dosage forms. Acceptance criteria should be set based on the

observed range of variation, and should take into account the dissolution profiles of

the batches that showed acceptable performance in vivo. Developmental data should

be considered when determining the need for either a dissolution procedure or a

particle size distribution procedure.

i) Particle size distribution: Quantitative acceptance criteria and a procedure for

determination of particle size distribution may be appropriate for oral suspensions.

Developmental data should be considered when determining the need for either a

dissolution procedure or a particle size distribution procedure for these formulations.

Particle size distribution testing should be performed at release. It may be performed

as an in-process test when justified by product development data. If these products

have been demonstrated during development to have consistently rapid drug release

characteristics, exclusion of a particle size distribution test from the specification

may be proposed.

Particle size distribution testing may also be proposed in place of dissolution testing;

justification should be provided. The acceptance criteria should include acceptable

particle size distribution in terms of the percent of total particles in given size ranges.

The mean, upper, and / or lower particle size limits should be well defined.

Acceptance criteria should be set based on the observed range of variation, and

should take into account the dissolution profiles of the batches that showed

acceptable performance in vivo, as well as the intended use of the product. The

potential for particle growth should be investigated during product development; the

acceptance criteria should take the results of these studies into account.

Specifications: New Chemical Drug Substances and Products

15

j) Redispersibility: For oral suspensions which settle on storage (produce sediment),

acceptance criteria for redispersibility may be appropriate. Shaking may be an

appropriate procedure.

The procedure (mechanical or manual) should be indicated. Time required to achieve

resuspension by the indicated procedure should be clearly defined. Data generated

during product development may be sufficient to justify skip lot testing, or

elimination of this attribute from the specification may be proposed.

k) Rheological properties: For relatively viscous solutions or suspensions, it may be

appropriate to include rheological properties (viscosity/specific gravity) in the

specification. The test and acceptance criteria should be stated. Data generated

during product development may be sufficient to justify skip lot testing, or

elimination of this attribute from the specification may be proposed.

l) Reconstitution time: Acceptance criteria for reconstitution time should be provided

for dry powder products which require reconstitution. The choice of diluent should be

justified. Data generated during product development may be sufficient to justify skip

lot testing or elimination of this attribute from the specification may be proposed.

m) Water content: For oral products requiring reconstitution, a test and acceptance

criterion for water content should be proposed when appropriate. Loss on drying is

generally considered sufficient if the effect of absorbed moisture vs. water of

hydration has been adequately characterized during the development of the product.

In certain cases a more specific procedure (e.g., Karl Fischer titration) may be

preferable.

3.3.2.3 Parenteral Drug Products: The following tests may be applicable to

parenteral drug products.

a) Uniformity of dosage units: This term includes both the mass of the dosage form

and the content of the active substance in the dosage form; a pharmacopoeial

procedure should be used. In general, the specification should one or the other but

not both and is applicable to powders for reconstitution. When weight variation is

applied for new drug products exceeding the threshold value to allow testing

uniformity by weight variation, applicants should verify during drug development

that the homogeneity of the product is adequate.

If appropriate (see section 2.3), these tests may be performed in-process; the

acceptance criteria should be included in the specification. This test may be applied

to both single-dose and multiple-dose packages.

For powders for reconstitution, uniformity of mass testing is generally considered

acceptable.

b) pH: Acceptance criteria for pH should be provided where applicable and the

proposed range justified.

c) Sterility: All parenteral products should have a test procedure and acceptance

criterion for evaluation of sterility. Where data generated during development and

validation justify parametric release, this approach may be proposed for terminally

sterilized drug products (see section 2.6).

d) Endotoxins/Pyrogens: A test procedure and acceptance criterion for endotoxins,

using a procedure such as the limulus amoebocyte lysate test, should be included in

the specification. Pyrogenicity testing may be proposed as an alternative to

endotoxin testing where justified.

e) Particulate matter: Parenteral products should have appropriate acceptance

criteria for particulate matter. This will normally include acceptance criteria for

Specifications: New Chemical Drug Substances and Products

16

visible particulates and / or clarity of solution, as well as for sub-visible particulates

as appropriate.

f) Water content: For non-aqueous parenterals, and for parenteral products for

reconstitution, a test procedure and acceptance criterion for water content should be

proposed when appropriate. Loss on drying is generally considered sufficient for

parenteral products, if the effect of absorbed moisture vs. water of hydration has been

adequately characterized during development. In certain cases a more specific

procedure (e.g., Karl Fischer titration) may be preferred.

g) Antimicrobial preservative content: For parenteral products needing an

antimicrobial preservative, acceptance criteria for preservative content should be

established. Acceptance criteria for preservative content should be based upon the

levels of antimicrobial preservative necessary to maintain microbiological quality of

the product at all stages throughout its proposed usage and shelf life. The lowest

specified concentration of antimicrobial preservative should be demonstrated to be

effective in controlling microorganisms by using a pharmacopoeial antimicrobial

preservative effectiveness test.

Testing for antimicrobial preservative content should normally be performed at

release. Under certain circumstances, in-process testing may suffice in lieu of release

testing where permitted. When antimicrobial preservative content testing is

performed as an in-process test, the acceptance criteria should remain part of the

specification.

Antimicrobial preservative effectiveness should be demonstrated during

development, during scaleup, and throughout the shelf-life (e.g., in stability testing:

see the ICH Guideline, “Stability Testing of New Drug Substances and Products”),

although chemical testing for preservative content is the attribute normally included

in the specification.

h) Antioxidant preservative content: Release testing for antioxidant content should

normally be performed. Under certain circumstances, where justified by

developmental and stability data, shelf-life testing may be unnecessary and in-

process testing may suffice in lieu of release testing. When antioxidant content

testing is performed as an in-process test, the acceptance criteria should remain part

of the specification. If only release testing is performed, this decision should be

reinvestigated whenever either the manufacturing procedure or the container/closure

system changes.

i) Extractables: Control of extractables from container/closure systems is considered

significantly more important for parenteral products than for oral liquids. However,

where development and stability data show evidence that extractables are

consistently below the levels that are demonstrated to be acceptable and safe,

elimination of this test can normally be accepted. This should be reinvestigated if the

container/closure system or formulation changes.

Where data demonstrate the need, acceptance criteria for extractables from the

container/closure components are considered appropriate for parenteral products

packaged in non-glass systems or in glass containers with elastomeric closures. This

testing may be performed at release only, where justified by data obtained during

development. The container/closure system components (e.g., rubber stopper, etc.)

should be listed, and data collected for these components as early in the development

process as possible.

j) Functionality testing of delivery systems: Parenteral formulations packaged in pre-

filled syringes, autoinjector cartridges, or the equivalent should have test procedures

Specifications: New Chemical Drug Substances and Products

17

and acceptance criteria related to the functionality of the delivery system. These may

include control of syringeability, pressure, and seal integrity (leakage), and/or

parameters such as tip cap removal force, piston release force, piston travel force, and

power injector function force. Under certain circumstances these tests may be

performed in-process. Data generated during product development may be sufficient

to justify skip lot testing or elimination of some or all attributes from the

specification.

k) Osmolarity: When the tonicity of a product is declared in its labeling, appropriate

control of its osmolarity should be performed. Data generated during development

and validation may be sufficient to justify performance of this procedure as an in-

process control, skip lot testing, or direct calculation of this attribute.

l) Particle size distribution: Quantitative acceptance criteria and a procedure for

determination of particle size distribution may be appropriate for injectable

suspensions. Developmental data should be considered when determining the need

for either a dissolution procedure or a particle size distribution procedure.

Particle size distribution testing should be performed at release. It may be performed

as an in-process test when justified by product development data. If the product has

been demonstrated during development to have consistently rapid drug release

characteristics, exclusion of particle size controls from the specification may be

proposed.

Particle size distribution testing may also be proposed in place of dissolution testing,

when development studies demonstrate that particle size is the primary factor

influencing dissolution; justification should be provided. The acceptance criteria

should include acceptable particle size distribution in terms of the percent of total

particles in given size ranges. The mean, upper, and / or lower particle size limits

should be well defined.

Acceptance criteria should be set based on the observed range of variation, and

should take into account the dissolution profiles of the batches that showed

acceptable performance in vivo and the intended use of the product. The potential for

particle growth should be investigated during product development; the acceptance

criteria should take the results of these studies into account.

m) Redispersibility: For injectable suspensions which settle on storage (produce

sediment), acceptance criteria for redispersibility may be appropriate. Shaking may

be an appropriate procedure. The procedure (mechanical or manual) should be

indicated. Time required to achieve resuspension by the indicated procedure should

be clearly defined. Data generated during product development may be sufficient to

justify skip lot testing, or elimination of this attribute from the specification may be

proposed.

n) Reconstitution time: Acceptance criteria for reconstitution time should be provided

for all parenteral products which require reconstitution. The choice of diluent should

be justified. Data generated during product development and process validation may

be sufficient to justify skip lot testing or elimination of this attribute from the

specification for rapidly dissolving products.

Specifications: New Chemical Drug Substances and Products

18

4. GLOSSARY

(The following definitions are presented for the purpose of this Guideline)

Acceptance criteria:

Numerical limits, ranges, or other suitable measures for acceptance of the results of

analytical procedures.

Chiral:

Not superimposable with its mirror image, as applied to molecules, conformations,

and macroscopic objects, such as crystals. the term has been extended to samples of

substances whose molecules are chiral, even if the macroscopic assembly of such

molecules is racemic.

Combination product:

A drug product which contains more than one drug substance.

Degradation product:

A molecule resulting from a chemical change in the drug molecule brought about over

time and/or by the action of e.g., light, temperature, pH, water, or by reaction with an

excipient and/or the immediate container/closure system. Also called decomposition

product.

Delayed Release:

Release of a drug (or drugs) at a time other than immediately following oral

administration.

Enantiomers:

Compounds with the same molecular formula as the drug substance, which differ in

the spatial arrangement of atoms within the molecule and are nonsuperimposable

mirror images.

Extended Release:

Products which are formulated to make the drug available over an extended period

after administration.

Highly Water Soluble Drugs:

Drugs with a dose/solubility volume of less than or equal to 250 mL over a pH range

of 1.2 to 6.8. (Example: Compound A has as its lowest solubility at 37± 0.5°C, 1.0

mg/mL at pH 6.8, and is available in 100 mg, 200 mg, and 400 mg strengths. This

drug would be considered a low solubility drug as its dose/solubility volume is greater

than 250 mL (400 mg/1.0 mg/mL = 400 mL).

Immediate Release:

Allows the drug to dissolve in the gastrointestinal contents, with no intention of

delaying or prolonging the dissolution or absorption of the drug.

Impurity:

(1) Any component of the new drug substance which is not the chemical entity

defined as the new drug substance. (2) Any component of the drug product which is

not the chemical entity defined as the drug substance or an excipient in the drug

product.

Specifications: New Chemical Drug Substances and Products

19

Identified impurity:

An impurity for which a structural characterization has been achieved.

In-process tests:

Tests which may be performed during the manufacture of either the drug substance

or drug product, rather than as part of the formal battery of tests which are

conducted prior to release.

Modified Release:

Dosage forms whose drug-release characteristics of time course and/or location are

chosen to accomplish therapeutic or convenience objectives not offered by

conventional dosage forms such as a solution or an immediate release dosage form.

Modified release solid oral dosage forms include both delayed and extended release

drug products.

New drug product:

A pharmaceutical product type, for example, tablet, capsule, solution, cream, etc.,

which has not previously been registered in a region or Member State, and which

contains a drug ingredient generally, but not necessarily, in association with

excipients.

New drug substance:

The designated therapeutic moiety, which has not previously been registered in a

region or Member State (also referred to as a new molecular entity or new chemical

entity). It may be a complex, simple ester, or salt of a previously approved drug

substance.

Polymorphism:

The occurrence of different crystalline forms of the same drug substance. This may

include solvation or hydration products (also known as pseudopolymorphs) and

amorphous forms.

Quality:

The suitability of either a drug substance or drug product for its intended use. This

term includes such attributes as the identity, strength, and purity.

Racemate:

A composite (solid, liquid, gaseous, or in solution) of equimolar quantities of two

enantiomeric species. It is devoid of optical activity.

Rapidly Dissolving Products:

An immediate release solid oral drug product is considered rapidly dissolving when

not less than 80% of the label amount of the drug substance dissolves within 15

minutes in each of the following media: (1) pH 1.2, (2) pH 4.0, and (3) pH 6.8.

Reagent:

A substance, other than a starting material or solvent, which is used in the

manufacture of a new drug substance.

Specifications: New Chemical Drug Substances and Products

20

Solvent:

An inorganic or an organic liquid used as a vehicle for the preparation of solutions or

suspensions in the synthesis of a new drug substance or the manufacture of a new

drug product.

Specification:

A list of tests, references to analytical procedures, and appropriate acceptance

criteria which are numerical limits, ranges, or other criteria for the tests described. It

establishes the set of criteria to which a drug substance or drug product should

conform to be considered acceptable for its intended use. "Conformance to

specifications" means that the drug substance and / or drug product, when tested

according to the listed analytical procedures, will meet the listed acceptance criteria.

Specifications are critical quality standards that are proposed and justified by the

manufacturer and approved by regulatory authorities.

Specific test:

A test which is considered to be applicable to particular new drug substances or

particular new drug products depending on their specific properties and/or intended

use.

Specified impurity:

An identified or unidentified impurity that is selected for inclusion in the new drug

substance or new drug product specification and is individually listed and limited in

order to assure the quality of the new drug substance or new drug product.

Unidentified impurity:

An impurity which is defined solely by qualitative analytical properties, (e.g.,

chromatographic retention time).

Universal test:

A test which is considered to be potentially applicable to all new drug substances, or

all new drug products; e.g., appearance, identification, assay, and impurity tests.

5. REFERENCES

International Conference on Harmonisation; "Impurities in New Drug Substances",

1995.

International Conference on Harmonisation; "Impurities in New Drug Products",

1996.

International Conference on Harmonisation; "Stability Testing of New Drug

Substances and Products", 1994.

International Conference on Harmonisation; "Text on Validation of Analytical

Procedures", 1994.

International Conference on Harmonisation; "Validation of Analytical Procedures:

Methodology", 1996.

International Conference on Harmonisation, "Residual Solvents in Pharmaceuticals",

1996.

International Conference on Harmonisation, “Specifications: Test Procedures and

Acceptance Criteria for Biotechnological/Biological Products”, 1999

Specifications: New Chemical Drug Substances and Products

21

6. ATTACHMENTS

Decision Trees #1 through #8

Specifications: New Chemical Drug Substances and Products

22

Specifications: New Chemical Drug Substances and Products

23

Specifications: New Chemical Drug Substances and Products

24

Specifications: New Chemical Drug Substances and Products

25

Specifications: New Chemical Drug Substances and Products

26

Specifications: New Chemical Drug Substances and Products

27

Specifications: New Chemical Drug Substances and Products

28

Specifications: New Chemical Drug Substances and Products

29

Specifications: New Chemical Drug Substances and Products

30

Specifications: New Chemical Drug Substances and Products

31