For Research Use Only. Not for use in diagnostic procedures.

QuantStudio

™

3 and 5 Real‑Time PCR

Systems

INSTALLATION, USE, AND MAINTENANCE

Firmware v1.6

Publication Number MAN0010407

Revision F

Life Technologies Holdings Pte Ltd | Block 33 | Marsiling Industrial Estate Road 3 | #07-06, Singapore 739256

For descriptions of symbols on product labels or product documents, go to thermofisher.com/symbols-definition.

Revision history: MAN0010407 F (English)

Revision Date Description

F 8 August 2024

•

Information about using tubes/tube strips was added (“Options for loading MicroAmp

™

consumables with

the QuantStudio

™

3 and 5 Real‑Time PCR Systems” on page40 and “Prepare samples using MicroAmp

™

tubes/tube strips with separate cap strips” on page43).

•

Caution information about flat caps for tubes was moved to “Prepare samples using MicroAmp

™

tubes/tube

strips with separate cap strips” on page43.

•

Information about instrument power issues during runs was added (“View run history and delete or transfer

files from the instrument” on page47).

•

Minor verbiage was updated.

E.0 31 January 2024

v1.6

•

The information about instrument settings was updated to indicate that this feature is available only to users

that are signed in when SAE mode is enabled (“Configure instrument settings” on page27).

•

The instructions to delete a run from the run history were updated to indicate that only an Administrator

can perform this function when SAE mode is enabled (

“View run history and delete or transfer files from the

instrument” on page47).

•

A data management feature was added to the settings (“Configure instrument settings” on page27).

•

Instructions were added to perform a self-verification test, to view the instrument logs, and to connect the

instrument to a network drive.

•

The instructions to set the date and time were updated. The date and time cannot be set if the instrument is

linked to the Thermo Fisher

™

Connect Platform.

•

The instructions to test the connection to the Thermo Fisher

™

Connect Platform were removed. This feature

is not available.

•

The requirements for the computer for the desktop software were updated.

•

The support that is provided for the computer for the desktop software was updated.

D.0 21 July 2021

Updates – describes new features in Firmware v1.4.x and other changes, including:

•

Updated the name of the cloud-based platform to Thermo Fisher

™

Connect.

•

Added instructions for connecting to the Thermo Fisher

™

Connect cloud-based platform.

•

Updated the firewall instrument-to-computer port number.

•

Updated licensing information.

•

Added Network and password security requirements section

•

Added Perform internal validations before software upgrades section

•

Added information for updating the firmware.

•

Update operating system to Windows

™

10 (64‑bit).

•

Added the MicroAmp

™

Optical Film Compression Pad as an optional accessory for the 96-well 0.2-mL block

when using a MicroAmp

™

Optical 96-Well Reaction Plate, including instructions to load and unload the plate

if using this accessory.

•

Specified that an instrument profile is only for the instrument. It is not related to any other account for the

system or the software.

•

Specified that if the connection between the instrument and the desktop software is interrupted during a run,

the instrument will complete the run. The EDS

file must be transferred manually to the desktop software with

a USB drive or through a network drive.

•

Changed all references to Bleach, 10% solution to Na-hypochlorite (0.1% v/v) solution

Revision Date Description

D.0

(contin

ued)

21 July 2021

•

Updated the calibration and verification schedule.

–

Specified that Background and Dye calibrations must be performed after an ROI/Uniformity

calibration.

–

Specified ROI/Uniformity calibration invalidates all other calibrations.

–

Added that the Background calibration can be used to obtain the most accurate data for the removal

of background fluorescence.

–

Specified that a Background calibration and a Dye calibration do not invalidate all other calibrations.

–

Added a recommendation that RNase P instrument verification be performed after instrument

calibrations.

•

Added troubleshooting information for RNase P verification.

•

Added troubleshooting information if the connection between the instrument and the computer is not

recognized.

•

Added storage and transport conditions to the environmental requirements.

•

Specified that restoring factory defaults can only be performed by an administrator and specified that the

most recent valid ROI/Uniformity, Background, and System Dye calibrations are not deleted when factory

defaults are restored.

C.0 16 December

2015

Updates – describes new features in Firmware v1.2.x, including:

•

Updated workflow to create an instrument profile

•

Streamlined workflow for connectivity to Thermo Fisher

™

Connect

•

Improved display of VeriFlex

™

Zones

•

Plate insert reminder before starting run

•

Support for 96-well Fast (0.1 mL) plates

B.0 1 October 2015

Updates – describes new features in Firmware v1.1.x, including:

•

Experiment runs: monitor real-time data, edit cycle number and lock screen during a run, view end plot, and

support for 384-well plates

•

File management: access Network folders, navigate folder structures and save templates on instrument,

and perform batch actions for

file management

•

Instrument configuration: support for Security, Audit, and e-Signature (SAE), smart monitoring, and choice

of server region

Includes information on software feature comparison, definitions of terms, parts of method, network connection

options, experiment types, desktop software installation.

A.0 23 April 2015

New document. Describes installation, operation, and maintenance of the QuantStudio

™

3 and 5 Real‑Time PCR

Systems.

The information in this guide is subject to change without notice.

DISCLAIMER: TO THE EXTENT ALLOWED BY LAW, THERMO FISHER SCIENTIFIC INC. AND/OR ITS AFFILIATE(S) WILL NOT BE

LIABLE FOR SPECIAL, INCIDENTAL, INDIRECT, PUNITIVE, MULTIPLE, OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH OR

ARISING FROM THIS DOCUMENT, INCLUDING YOUR USE OF IT.

Important Licensing Information: These products may be covered by one or more Limited Use Label Licenses. By use of these

products, you accept the terms and conditions of all applicable Limited Use Label Licenses.

Trademarks: All trademarks are the property of Thermo Fisher Scientific and its subsidiaries unless otherwise specified. TaqMan is

a trademark of Roche Molecular Systems, Inc., used under permission and license. Cy is a registered trademark of GE Healthcare.

Windows is a trademark of Microsoft Corporation. Chrome is a trademark of Google LLC. Core and Intel are trademarks of Intel

Corporation.

©2015-2024 Thermo Fisher Scientific Inc. All rights reserved.

Contents

About thisguide .......................................................... 10

Purpose ...................................................................... 10

■

CHAPTER1Productinformation ................................................ 11

Network and password security requirements ..................................... 11

Network configuration andsecurity .......................................... 11

Passwordsecurity ......................................................... 11

Perform internal validations before software upgrades .............................. 11

Update the instrumentfirmware .................................................. 12

Back up theinstrument ..................................................... 12

Instrument hardwaredescription ................................................. 12

Instrument overview ....................................................... 12

Parts of theinstrument ..................................................... 16

Softwaredescription ........................................................... 16

Instrument, desktop, and cloud software features .............................. 16

Folders, templates, experiments, and projects ................................. 17

Third-party software ....................................................... 19

Network connectionoptions ..................................................... 19

Types ofruns .................................................................. 19

■

CHAPTER2Start, sign on, and configure theinstrument ..................... 22

Installation and instrumentverification ............................................ 22

Precautions foruse ............................................................. 23

Power on theinstrument ........................................................ 23

Parts of the home screen ....................................................... 24

Use the instrument without signingin ............................................. 26

Create a new instrumentprofile .................................................. 26

Signin ........................................................................ 27

Signout ...................................................................... 27

Configure instrumentsettings .................................................... 27

4

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

■

CHAPTER3Create and run experiments on theinstrument .................. 31

Workflow ..................................................................... 32

Options for running an experiment ............................................... 33

Create and run an experiment from a template ................................ 33

Run an experiment from a savedfile ......................................... 33

Repeat the last instrumentrun ............................................... 34

Edit an experiment before starting arun .......................................... 35

Enter or edit template properties ............................................. 35

Edit the runmethod ........................................................ 36

Define, assign, and view welldetails ......................................... 39

Options for loading MicroAmp

™

consumables with the QuantStudio

™

3 and 5

Real‑Time PCR Systems ...................................................... 40

Load and unload the plate ...................................................... 40

Load and unload a plate in theinstrument .................................... 40

(If applicable) load and unload a plate in the instrument with a compressionpad ... 41

Prepare samples using MicroAmp

™

tubes/tube strips with separate capstrips ......... 43

View, pause, or stop arun ....................................................... 45

View real-time data and plots on the instrument touchscreen .................... 45

Pause or stop an instrumentrun ............................................. 45

Adjust the display of real-time plots on the instrument touchscreen .............. 46

Lock the touchscreen during arun ........................................... 46

Transfer, view, or manage files and results ......................................... 46

Transfer EDS files from the instrument home screen ............................ 46

View run history and delete or transfer files from theinstrument ................. 47

Manage templates (EDTfiles) ................................................ 47

■

CHAPTER4Calibrate and verify instrument performance ..................... 49

Calibration and verificationschedule ............................................. 49

Calibrationdescriptions ......................................................... 50

View the calibration status and set reminders ...................................... 51

View calibration status and set reminders in theinstrument ..................... 51

View calibration status and set reminders in Thermo Fisher

™

ConnectPlatform .... 51

Perform ROI/uniformity, background, and dye calibrations .......................... 52

Workflow: Calibration ...................................................... 52

Prepare a calibration plate .................................................. 53

Perform calibrations ........................................................ 54

View calibration images and transfer results to a USBdrive ..................... 56

Troubleshoot calibration failure .............................................. 57

Identifycontamination ...................................................... 57

Create a background plate (optional) ......................................... 58

Contents

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

5

Perform instrument verification using RNase P plates ............................... 59

Instrument verificationdescription ........................................... 59

RNaseP instrument verification plate ........................................ 59

Performance specifications pass criteria ...................................... 61

Prepare an RNase P plate ................................................... 61

Perform RNasePverification ................................................ 62

Troubleshoot verification failure .............................................. 63

Calibrate customdyes .......................................................... 65

Custom dyes overview ..................................................... 65

Use a dilution series to determine an optimal custom dye concentration .......... 65

Calibrate the customdye ................................................... 68

Calibrate for a custom melt curve experiment ...................................... 72

■

CHAPTER5Maintain theinstrument ............................................ 74

Back up or restore theinstrument ................................................ 74

Perform a self-verification test ................................................... 75

View instrumentlogs ........................................................... 75

Configure the networkdrive ..................................................... 75

Create a shared networkfolder .............................................. 76

Determine the IP address of the computer .................................... 77

Determine the DNSname ................................................... 77

Decontaminate the sampleblock ................................................ 77

Materials required .......................................................... 77

Clean the sampleblock ..................................................... 78

Detailed procedures for cleaning the sampleblock ............................. 79

Replace the instrumentfuses .................................................... 80

Materials required .......................................................... 80

Replace thefuses .......................................................... 80

Power on or o, store, andmove ................................................. 81

Enable sleepmode ........................................................ 81

Power on theinstrument .................................................... 81

Power o theinstrument .................................................... 82

Prepare the instrument to store, move, orship ................................. 82

Move theinstrument ....................................................... 82

Return the instrument for service ............................................ 83

Contents

6

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

■

CHAPTER6Configure the instrument and manage instrumentprofiles ..... 84

Initial start‑up .................................................................. 84

Manageprofiles ................................................................ 85

Create an administrator instrument profile during initial start-up ................. 85

Manage all instrument profiles (Administratoronly) ............................. 85

Edit an instrumentprofile ................................................... 86

Link an instrument profile to Thermo Fisher

™

Connect .............................. 86

Recommended order to set upprofiles ....................................... 87

Overview of local instrument profiles and Thermo Fisher

™

Connectprofiles ....... 87

Thermo Fisher

™

Connect Platform instrument profile roles andfunctions ......... 88

Link the instrument to your Thermo Fisher

™

Connect Platformaccount ........... 88

Link a local profile to a Thermo Fisher

™

Connectprofile ......................... 89

Unlink a Thermo Fisher

™

Connectaccount .................................... 91

If you link when you are signed in to theinstrument ............................ 91

Change the PIN for a Thermo Fisher

™

Connectprofile .......................... 92

Enable SAE mode (Administratoronly) ............................................ 92

Require instrument profile sign-in (Administratoronly) .............................. 93

Enable remote instrument monitoring (Administratoronly) ........................... 93

Update instrument software (Administratoronly) ................................... 94

Restore factorydefaults ......................................................... 94

Configure thenetwork .......................................................... 94

Set up a wiredconnection .................................................. 95

Set up a wirelessconnection ................................................ 95

Select a region for the Thermo Fisher

™

Connect Platform (Administratoronly) ......... 96

Manage the instrument name (Administratoronly) .................................. 96

Set the date and time (Administratoronly) ......................................... 96

Manage the signout timer (Administrator only) ..................................... 97

■

APPENDIXAInstall and connect the instrument to anetwork ................ 98

Workflow: Install and connect to anetwork ........................................ 98

Before youbegin ............................................................... 99

Unpack and install theinstrument ................................................ 99

Power on and follow the startup wizard .......................................... 100

Connect the computer to the instrument directly or to aLAN ....................... 100

Instrument and computerconnections ........................................... 101

Contents

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

7

Download and install the desktop software ....................................... 102

Computer requirements for the desktop software ............................. 102

Download the desktop software ............................................ 103

Install the desktop software ................................................ 103

Networking ................................................................... 103

Supported options for instrument and computerconnections .................. 103

Control and monitor networkedinstruments .................................. 105

Ethernet port overview .................................................... 105

Firewall ports that must beopen ............................................ 105

Networking guidelines and best practices ................................... 106

■

APPENDIXBTroubleshooting .................................................. 107

■

APPENDIXCParts and materials .............................................. 109

Kits, consumables, accessories, and reagents .................................... 109

Consumables (96‑well, 0.2‑mLformat) ........................................... 109

384-wellconsumables ......................................................... 110

Consumables (96-well, 0.1-mLformat) .......................................... 111

Accessories .................................................................. 112

General-use materials andconsumables ......................................... 112

■

APPENDIXDInstrument specification andlayout ............................ 113

Configured systemdimensions ................................................. 114

Instrument clearances ..................................................... 115

Electrical requirements ........................................................ 115

Environmental requirements .................................................... 116

Network requirements ......................................................... 116

■

APPENDIXESafety .............................................................. 118

Symbols on thisinstrument .................................................... 118

Conformitysymbols ...................................................... 120

Safety alerts on thisinstrument ................................................. 121

Location of safety labels on theinstrument .................................. 121

Safety information for instruments not manufactured by Thermo FisherScientific ..... 122

Instrumentsafety ............................................................. 122

General ................................................................. 122

Physical injury ............................................................ 123

Electricalsafety .......................................................... 124

Cleaning anddecontamination ............................................. 124

Contents

8

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

Safety and electromagnetic compatibility (EMC) standards ......................... 124

Safetycompliance ........................................................ 125

EMC .................................................................... 125

Environmentaldesign ..................................................... 126

Chemicalsafety .............................................................. 127

Biological hazardsafety ....................................................... 128

■

APPENDIXFDocumentation and support ..................................... 129

Relateddocumentation ........................................................ 129

Obtain information from the Help system ........................................ 129

Customer and technical support ................................................ 129

Limited product warranty ...................................................... 130

Index ..................................................................................... 131

Contents

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

9

About this guide

Purpose

This guide provides information about installing, using, and maintaining the QuantStudio

™

3 and 5

Real‑Time PCR Systems.

Note: For information and instructions on performing experiments on these systems, see QuantStudio

™

Design and Analysis Desktop Software User Guide (Pub. No. MAN0010408).

10

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

Product information

■

Network and password security requirements ............................................ 11

■

Perform internal validations before software upgrades ..................................... 11

■

Update the instrumentfirmware ........................................................ 12

■

Instrument hardwaredescription ....................................................... 12

■

Softwaredescription .................................................................. 16

■

Network connectionoptions ........................................................... 19

■

Types ofruns ........................................................................ 19

Network and password security requirements

Network configuration and security

The network configuration and security settings of your laboratory or facility (such as firewalls, anti-

virus software, network passwords) are the sole responsibility of your facility administrator, IT, and

security personnel. This product does not provide any network or security configuration files, utilities, or

instructions.

If external or network drives are connected to the software, it is the responsibility of your IT personnel

to ensure that such drives are configured and secured correctly to prevent data corruption or loss. It

is the responsibility of your facility administrator, IT, and security personnel to prevent the use of any

unsecured ports (such as USB, Ethernet) and ensure that the system security is maintained.

Password security

Thermo Fisher Scientific strongly recommends that you maintain unique passwords for all accounts in

use on this product. All passwords should be reset upon first sign in to the product. Change passwords

according to your organization's password policy.

It is the sole responsibility of your IT personnel to develop and enforce secure use of passwords.

Perform internal validations before software upgrades

IMPORTANT!

If you have a validated workflow, you must perform all internal validations as required by

your organization's standard operating procedures before performing a software upgrade.

1

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

11

Update the instrument firmware

If your instrument is not on version 1.6 or later of the firmware you must update the firmware to

access the features and updates described in Revision E.0 of the revision history. For information on

updating your firmware, see https://www.thermofisher.com/us/en/home/global/forms/life-science/

quantstudio-3-5-software.html.

Prior to updating your firmware, we recommend you perform a backup. For information on performing a

backup, see “Back up the instrument” on page12.

Back up the instrument

1.

In the home screen, touch Settings4Maintenance and Service4Backup/Restore.

2.

Touch Backup Instrument.

3.

Select a location to store the backup settings for your instrument.

4.

If backing up to a USB drive, insert a USB drive into the front-panel USB port.

5.

Enter a backup file name, then touch Done.

6.

Select the elements to backup, or leave them all selected.

7.

Touch Backup.

Instrument hardware description

Instrument overview

The QuantStudio

™

3 and 5 Real‑Time PCR Systems use fluorescence-based polymerase chain reaction

(PCR) reagents to perform:

•

Quantitative detection of target nucleic acid sequences (targets).

•

Qualitative detection of targets (endpoint analysis, genotyping experiments, and presence/absence

experiments).

•

Qualitative analysis of the PCR product (post-PCR melt curve analysis).

Chapter1Product information

Update the instrument firmware

1

12

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

The following fixed-block configurations are available:

QuantStudio

™

3 Real-Time PCR System QuantStudio

™

5 Real‑Time PCR System

•

96-Well VeriFlex

™

0.2-mL Block (4Color)

•

96-Well VeriFlex

™

0.1-mL Block (4Color)

•

96-Well VeriFlex

™

0.2-mL Block (6ColorDe‑coupled)

•

384-Well Block (5Color)

•

96–Well VeriFlex

™

0.1-mL Block (6ColorDe‑coupled)

The instrument can be run directly from the touchscreen to create and start experiments. To design

experiments or to analyze data, the instrument can be integrated with the QuantStudio

™

Design and

Analysis Software.

An optional barcode scanner and optional wireless adapter can be purchased separately.

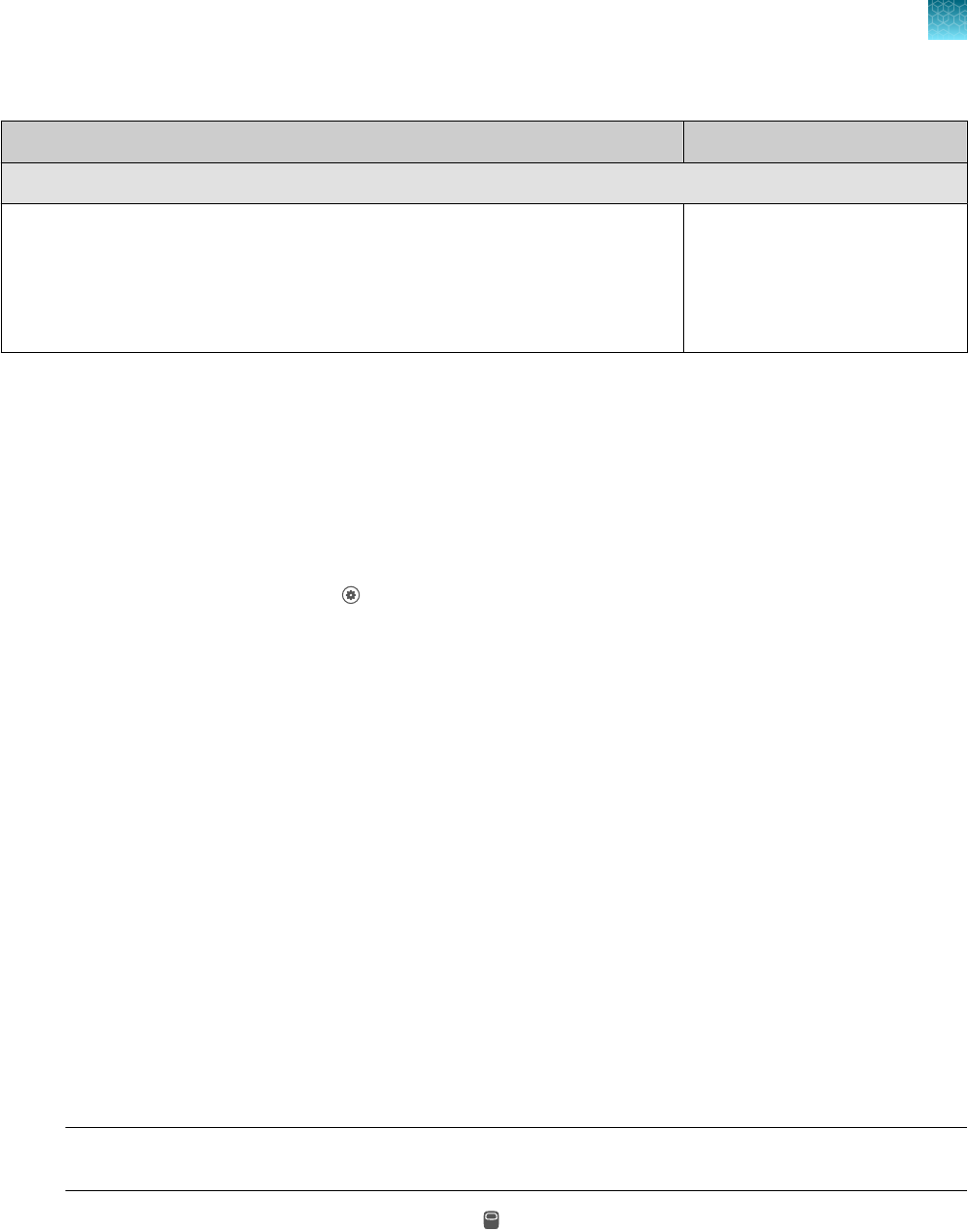

Instrument filters and supported dyes

System dyes

The instruments use a coupled four-color, coupled five-color, or de-coupled six-color filter set that

supports the dyes shown in the following table and figure. For more information about available spectral

dye calibration kits, contact Support.

Peak

filter

Color

Filter wavelength (nm)

[1]

Factory-calibrated dyes Example customdyes

Excitation Emission

x1-m1 Blue 470 ± 15nm 520 ± 15nm

FAM

™

dye, SYBR

™

Green

dye

SYT09

x2-m2 Green 520 ± 10nm 558 ± 12nm VIC

™

dye

JOE

™

dye,

HEX

™

dye, TET

™

dye

[2]

x3-m3 Yellow 550 ± 10nm 587 ± 10nm

NED

™

dye, TAMRA

™

dye,

ABY

™

dye

Cy

®

3 dye

x4-m4 Orange 580 ± 10nm 623 ± 14nm ROX

™

dye, JUN

™

dye Texas Red

™

dye

x5-m5 Red 640 ± 10nm 682 ± 14nm

MUSTANG PURPLE

™

dye,

Cy

®

5

LIZ

™

dye

x6-m6

Deep-

Red

662 ± 10nm 711 ± 12nm None

[3]

Cy

®

5.5 dye

[1]

The central wavelengths are the optimized wavelengths.

[2]

The HEX

™

and TET

™

dyes from Thermo Fisher Scientific fall within the emission wavelength range of the system, therefore they can

be added and adapted for use on the instrument.

[3]

This filter set currently does not support any dyes supplied by Thermo Fisher Scientific.

Chapter1Product information

Instrument hardware description

1

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

13

Filters

Wavelength

(nm)

1

2

3

4

5

x1-m1 x2-m2

x3-m3

x4-m4

x5-m5 x6-m6

Emission

Spectra

1

x1-m1 — FAM

™

dye, SYBR

™

Green dye

2

x2-m2 — VIC

™

dye

3

x3-m3 — ABY

™

dye, NED

™

dye, Cy

®

3 dye, TAMRA

™

dye

4

x4-m4 — JUN

™

dye, ROX

™

dye, Texas Red

™

dye

5

x5-m5 — Cy

®

5 dye, MUSTANG PURPLE

™

dye

Custom dyes

The instrument can run assays designed with custom dyes.

Custom dyes include:

•

Dyes that are not supplied by Thermo Fisher Scientific.

•

Dyes or formulations of dyes that are not system dyes for the instrument.

To use a custom dye on the instrument, review the following requirements.

•

Calibrate the instrument for the custom dye (see “Calibrate custom dyes” on page65).

•

Ensure that the custom dye excites between 455 – 672 nm and emits between 505 – 723 nm.

•

Select a custom dye that does not overlap with other dyes used in the run (see the filter-

wavelength table in “System dyes” on page13).

•

The custom dye must be attached to the 5' end of a short DNA oligonucleotide consisting of the

first two bases of the probe sequence without a quencher at the 3'end.

Chapter1Product information

Instrument hardware description

1

14

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

About data collection

The instrument collects raw fluorescence data at dierent points during the PCR cycle, depending on

the type of run performed.

When you create an experiment template (EDT file) in the software, you can customize the optical filter

channels through which the instrument collects data. You can specify a filter channel set for all PCR

thermal protocols and, optionally, a dierent filter set for the melt curve stages.

Run type Experiment type Data collection point

Real-time

•

Standard curve

•

Relative standard

curve

•

Comparative C

T

(ΔΔC

T

)

•

Melt curve

During the thermal cycling protocol.

Typical timing is to collect data at each cycle of a PCR stage

or continuously during a melt stage.

Post-PCR

(endpoint)

•

Genotyping

•

Presence/ Absence

•

After thermal cycling is completed.

For Presence/Absence and Genotyping experiments,

data collection before the PCR cycle is optional, but

recommended.

•

(Optional) Before thermal cycling starts.

Collecting data during the run can confirm genotyping

results by viewing traces in allelic discrimination plots or

viewing genotyping calls at earlier cycles.

Blocks with VeriFlex

™

Zones

Applied Biosystems

™

VeriFlex

™

technology provides independent temperature zones that oer

enhanced functionality and precise control over your real-time PCR runs.

QuantStudio

™

3 System QuantStudio

™

5 System

Three programmable VeriFlex

™

Zones. Six programmable VeriFlex

™

Zones.

[1]

[1]

Only applicable for 96-well 0.2-mL and 0.1-mL blocks.

Chapter1

Product information

Instrument hardware description

1

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

15

These independent zones are ideal for real-time PCR optimization or the ability to run multiple

experiments in the same run. Unlike standard gradients which give a sigmoidal temperature curve

across the columns, blocks with VeriFlex

™

Zones help deliver accurate temperatures across every zone.

Parts of the instrument

1

2

3

1

Touchscreen – Controls the instrument.

2

USB port – For connection to an external network drive or external data storage device.

3

Instrument drawer – Contains sample plate.

The instrument includes three additional USB ports on the back of the instrument.

Note: The instrument recognizes only one external storage device at a time for data transfer.

Software description

Instrument, desktop, and cloud software features

The instrument software and the QuantStudio

™

Design and Analysis Software (desktop and Thermo

Fisher

™

Connect Platform) include the features described below.

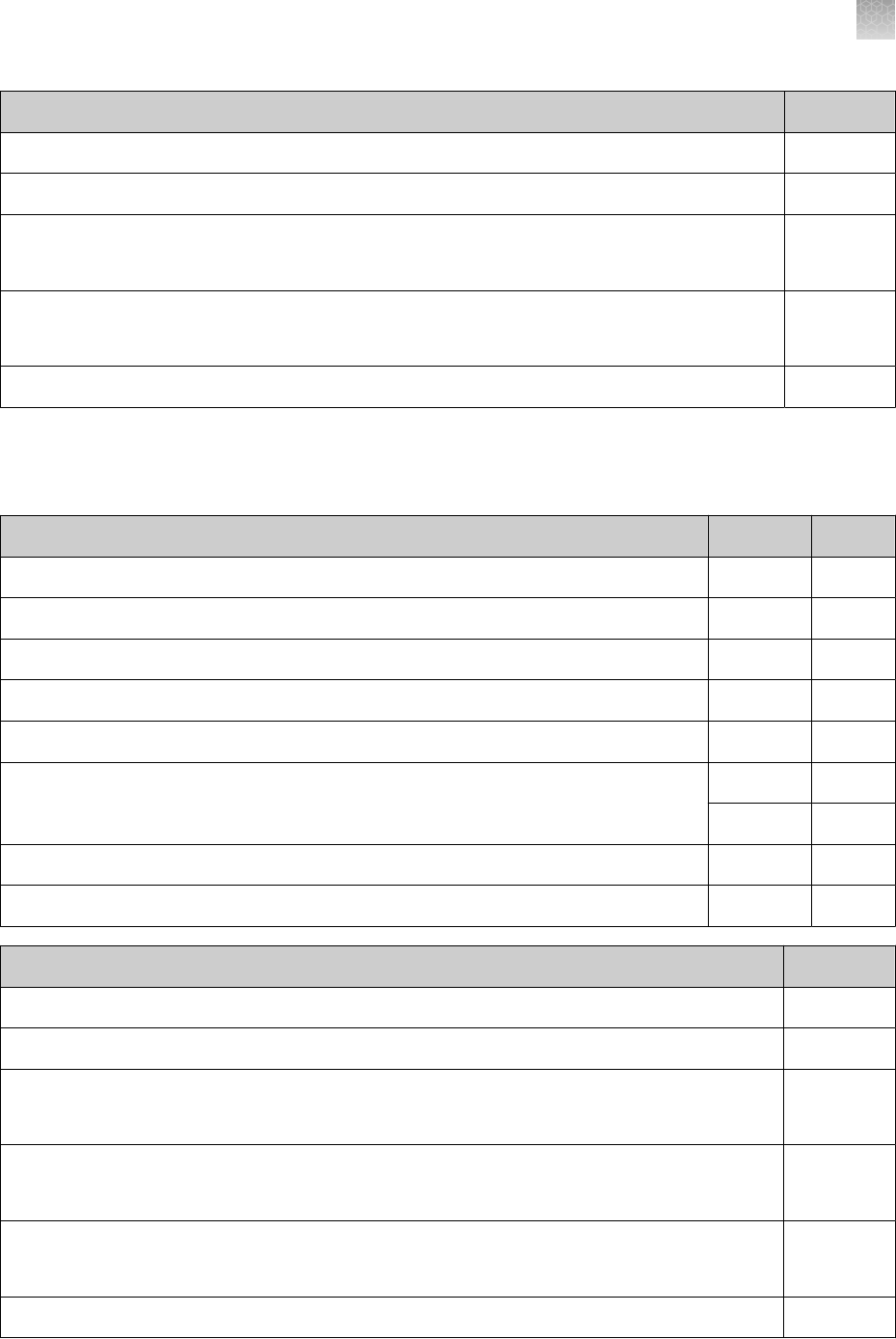

Feature

Instrument Desktop

Thermo Fisher

™

Connect Platform

Use as guest (no sign in) ✓ ✓

[1]

—

Create templates (unlocked or locked) — ✓ ✓

Edit unlocked templates ✓ ✓ ✓

Edit locked templates (password assigned by template creator

required)

— ✓ ✓

Load system or user-created templates (EDT file) to instrument ✓ ✓ —

Chapter1Product information

Software description

1

16

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

(continued)

Feature Instrument Desktop

Thermo Fisher

™

Connect Platform

Change experiment settings in template (EDT file) loaded on

the instrument

Settings that can be changed in a locked template (no

password required):

•

Properties: All settings

•

Method: No changes allowed

•

Plate: Sample names

Settings that can be changed in an unlocked template:

•

Properties: All settings

•

Method: All settings

•

Plate: Sample names

✓ — —

Load plate in instrument ✓ — —

Start run ✓ ✓ —

View real-time data during a run ✓ ✓ ✓

View instrument status (running, calibration needed, and so on) ✓ — ✓

Analyze results — ✓ ✓

Set calibration reminders ✓ — ✓

Review exported calibration or RNaseP verification results — ✓ ✓

(only RNase P)

[1]

Login required if the Security, Audit, and e-Signature (SAE) module is enabled (QuantStudio

™

5 System only)

Folders, templates, experiments, and projects

Term

Definition Supported in

Folders in Load

Experiment

Location in which you can store templates (EDT files) on the

instrument:

•

My Instrument – Displayed if you are signed in

•

Public – Location in which all experiments run by guest users

are stored

•

USB – USB for manual transfer to and from a computer

•

Post Read – If you run an endpoint experiment, the pre-read

experiment is automatically saved in this folder for post-read

analysis

Instrument

Chapter1Product information

Software description

1

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

17

(continued)

Term

Definition Supported in

Experiment

Template File

(EDT)

Default settings for an instrument run, can be modified before

instrument run.

Two types:

•

Factory-provided, accessed from Open Template (instrument)

or Create Experiment (desktop or Thermo Fisher

™

Connect

Platform)

•

User-created, accessed from Load Experiment

Instrument

Desktop

Thermo Fisher

™

Connect Platform

Experiment Run

File (EDS)

Settings and data for a completed instrument run. Instrument

Desktop

Thermo Fisher

™

Connect Platform

Template and

experiment

components

Instrument Desktop

Thermo Fisher

™

Connect

Platform

Properties

•

Experiment file name

•

Reagent information

(Reagent barcode, Lot#)

•

Plate barcode

•

Data management (location

for auto-transfer of data)

•

Comments (Tags are not

used at this time)

•

Experiment file name

•

Plate barcode

•

User name

•

Instrument type

•

Block type

•

Experiment type

•

Chemistry (reagent information)

•

Run mode

•

Comments

•

(Thermo Fisher

™

Connect Platform only) Notifications

Method Thermal cycling conditions Thermal cycling conditions

Plate Sample names

You cannot edit targets/SNP

assays or tasks on the

instrument.

Define and assign samples, targets or SNP assays, and tasks in

the Quick Setup and Advanced Setup panes of the Plate tab.

Run Start and monitor a run in

progress

View: time remaining and

temperature, method, plots

Pause, resume, stop a run

Start and monitor a run in

progress

View: time remaining and

temperature, method, plots

Monitor a run in progress (link

to Thermo Fisher

™

Connect

Platform Instrument Details)

View: time remaining and

temperature, method, plots

Chapter1Product information

Software description

1

18

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

(continued)

Template and

experiment

components

Instrument Desktop

Thermo Fisher

™

Connect

Platform

Results Not applicable Review plots

Export Not applicable Export results

Third-party software

Before installing third-party software on the computer running QuantStudio

™

Design and Analysis

Software, confirm that the third-party software will not do the following:

•

Restrict Ethernet communication.

•

Interfere with instrument or computer operation.

Network connection options

You can connect an instrument to a network or computer in the configurations listed below. For specific

information on networking, see “Networking” on page103.

Direct connection

Local area network (LAN) connection

Thermo Fisher

™

Connect Platform

connection

wired wired or wireless wired or wireless

LAN

LAN

LAN

Types of runs

Purpose

Description

Standard curve run

Determines absolute

target quantity in

samples.

1.

The software measures amplification of the target in a standard dilution series and

in test samples.

2.

The software generates a standard curve using data from the standard dilution

series.

3.

The software uses the standard curve to interpolate the absolute quantity of target

in the test samples.

Chapter1Product information

Network connection options

1

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

19

Purpose

Description

Relative standard curve run

Determines relative target

quantity in samples.

1.

The software measures amplification of the target of interest and of an endogenous

control target in a standard dilution series, in a reference (calibrator) sample, and in

test samples.

The endogenous control is a target that is expressed equally in all samples;

examples of endogenous controls are β‐actin, GAPDH, and 18S ribosomal RNA.

The software can algorithmically incorporate multiple endogenous control targets in

relative

quantification calculations.

The reference sample is used as the basis for relative quantification results (or

1× sample). For example, in a study of drug eects on gene expression, an

untreated control is an appropriate reference sample.

2.

The software generates standard curves for the target of interest and the

endogenous control using data from the corresponding standard dilution series.

3.

The software uses the standard curves to interpolate the quantities of the target of

interest and the endogenous control in each sample. The target quantity in each

sample is then normalized to the sample's endogenous control quantity.

4.

To determine the relative quantity of the target in test samples, the software divides

the normalized target quantity in the sample by the normalized target quantity in

the reference sample.

Comparative C

t

(ΔΔC

t

) run

Determines relative target

quantity in samples.

1.

The software measures amplification of the target of interest and of an endogenous

control target in a reference (calibrator) sample and in test samples.

The endogenous control is a target that is expressed equally in all samples;

examples of endogenous controls are β‐actin, GAPDH, and 18S ribosomal RNA.

The software can algorithmically incorporate multiple endogenous control targets in

relative

quantification calculations.

The reference sample is used as the basis for relative quantification results (or

1× sample). For example, in a study of drug eects on gene expression, an

untreated control is an appropriate reference sample.

2.

The measurements for the target of interest are normalized to the endogenous

control.

3.

To determine the relative quantity of the target in test samples, the software

compares the normalized ΔC

q

(ΔC

t

or ΔC

rt

) for the sample to the normalized

ΔC

q

(ΔC

t

or ΔC

rt

) for the reference sample.

Chapter1Product information

Types of runs

1

20

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

Purpose

Description

Genotyping run

Detects single nucleotide

polymorphism (SNP)

variants of a target

nucleic acid sequence.

Genotyping runs use preformulated TaqMan

™

SNP Genotyping Assays that include the

following components:

•

Two sequence-specific primers for amplification of sequences containing the SNP

of interest

•

Two allele-specific TaqMan

™

probes for Allele 1 and Allele 2

1.

The software normalizes the fluorescence of the reporter dyes to the fluorescence

of the passive reference dye in each well.

2.

The software plots the normalized reporter dye signal of each sample well on

an Allelic Discrimination Plot, which contrasts the reporter dye intensities of the

allele-specific probes.

3.

The software algorithmically clusters the sample data, and assigns a genotype call

to the samples of each cluster according to its position on the plot.

Presence/absence run

Determines the presence

or absence of a target

nucleic acid sequence in

a sample.

The software calls the target present or absent based on an algorithmically determined

call threshold. (The call threshold is dierent from the C

t

threshold; the C

t

threshold is

not used to make calls.)

Melt curve run

Determines the melting

temperature (T

m

) of the

amplification products

of a PCR that used

intercalating dyes.

In the software, melt curve analysis is included in the default run method for any run

type that uses intercalating dyes.

1.

The software plots a melt curve based on the fluorescence of the dye with respect

to change in temperature.

2.

Using the melt curve, the software calculates the melting temperature (T

m

).

Chapter1Product information

Types of runs

1

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

21

Start, sign on, and configure the

instrument

■

Installation and instrumentverification .................................................. 22

■

Precautions foruse ................................................................... 23

■

Power on theinstrument .............................................................. 23

■

Parts of the home screen .............................................................. 24

■

Use the instrument without signingin ................................................... 26

■

Create a new instrumentprofile ........................................................ 26

■

Signin .............................................................................. 27

■

Signout ............................................................................. 27

■

Configure instrumentsettings .......................................................... 27

Installation and instrument verification

Before the first use of the instrument, complete the following tasks:

•

Install the instrument (see “Unpack and install the instrument” on page99).

•

Verify instrument performance (see “Perform instrument verification using RNase P plates” on

page59).

Note:

·

Instruments are factory calibrated, so no calibration is necessary at installation. However, we

recommend that you verify instrument performance before using the instrument.

·

Regular calibration and verification should be performed according to the calibration and

verification schedule (see “Calibration and verification schedule” on page49).

2

22

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

Precautions for use

CAUTION! PHYSICAL INJURY HAZARD. Do not remove the instrument cover. There are no

components inside the instrument that you can safely service yourself. If you suspect a problem,

contact technical support.

CAUTION! FIRE HAZARD. For continued protection against the risk of fire, replace fuses only with

listed and certified fuses of the same type and rating as those currently in the instrument.

CAUTION! PHYSICAL INJURY HAZARD. During instrument operation, the sample block

temperature can reach 100°C. Allow it to cool to room temperature before handling.

CAUTION! Before using a cleaning or decontamination method other than those recommended by

Thermo Fisher Scientific, confirm with Thermo Fisher Scientific that the proposed method will not

damage the instrument.

CAUTION! Use flat caps for tubes. Rounded caps can damage the heated cover.

Power on the instrument

1.

Touch anywhere on the touchscreen to determine if the instrument is in sleep mode. If the home

screen is displayed, the instrument is already powered on.

2.

If the home screen does not display, power on the

instrument by pressing the switch on the rear panel.

If left unattended, the instrument automatically enters sleep

mode (enabled by default) to conserve power.

Note: To customize the sleep mode setting, touch

Settings4Instrument Settings4Sleep Mode.

Chapter2Start, sign on, and configure the instrument

Precautions for use

2

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

23

Parts of the home screen

4

2

9

1

5

6

8 7

3

1

Avatar and Instrument name

2

Eject icon

3

Help icon

4

Status dial

5

Current user name; instrument block type

6

Settings button

7

Buttons for accessing EDT files

8

Connectivity icons

9

Sign In (or My Profile) button

Chapter2Start, sign on, and configure the instrument

Parts of the home screen

2

24

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

Table1Parts of the home screen

Element of the home

screen

Function

For more information,

see...

Avatar and Instrument

name

Set by the administrator to uniquely identify instrument. “Manage the instrument

name (Administrator

only)” on page96.

Eject icon Touch to open or close the instrument drawer. —

Help icon Touch to launch the touchscreen Help system to access step-by-

step instructions.

—

Status dial

•

When the instrument is in use – Displays the sample block

temperature, the elapsed run time, and the run status.

You can swipe the dial to the left or touch to access

real-time views of the run.

•

When the instrument is not in use – Displays Set up run. You

can start a run by touching the status dial.

•

When the instrument is locked – Displays a lock icon ( )

within the status dial.

—

Current user name

and block type

Displays the user name of the current signed-in user and the

instrument block type.

Note: If no user is signed-in, the instrument defaults to the Guest

profile.

—

Settings button Touch Settings to configure, calibrate, or learn about the

instrument.

“Configure instrument

settings” on page27.

Buttons for accessing

experiment and

template files

Load Experiment – Touch to open a user-created EDT file from

a Thermo Fisher

™

Connect Platform account, USB, instrument

folder, or network drive.

“Run an experiment

from a saved file” on

page33.

Open Template – Touch to open a system EDT template file. “Create and run an

experiment from a

template” on page33.

Run Last – Touch to open the last EDT file run on the instrument.

•

If you are signed-in, the file opened will be the last file you

ran when signed-in.

•

If you are not signed-in, the file opened will be the last file the

guest profile ran.

“Repeat the last

instrument run” on

page34.

Connectivity icons

•

—The instrument is connected to a wired network.

•

—The instrument is wirelessly connected.

•

—A USB drive is plugged into the instrument.

•

—The instrument is linked to a Thermo Fisher

™

Connect

Platform account.

—

Chapter2Start, sign on, and configure the instrument

Parts of the home screen

2

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

25

Table 1 Parts of the home screen(continued)

Element of the home

screen

Function

For more information,

see...

Sign In button

(My Profile button

when a user is signed

in)

•

Touch Sign In to sign into an instrument profile and link to

a Thermo Fisher

™

Connect Platform account.

•

Touch My Profile to change instrument profile settings,

link to a Thermo Fisher

™

Connect Platform account, or lock

the instrument during a run.

“Sign in” on page27.

Use the instrument without signing in

If the instrument is configured by an Administrator to allow guest access ( Settings4Manage

Users4Sign In Required set to o), you can use the instrument without signing in.

The following limits are in place if you do not sign in to the instrument:

•

All actions are recorded to Guest user profile.

•

You have access only to the Public folder for selecting and storing experiments.

•

You cannot transfer data to Thermo Fisher

™

Connect Platform (only to USB or network drive).

Create a new instrument profile

1.

In the home screen, touch SignIn, then touch Get Started.

2.

Touch Name, enter a username, then touch Done.

3.

Touch PIN Code, enter a four-digit numerical password, then touch Enter.

Note: Touch the Show PIN checkbox to switch PIN display on or o.

4.

Touch Confirm PIN, then repeat step2.

5.

Touch Create profile.

6.

Sign in to the profile you just created.

Note: To enable access to Thermo Fisher

™

Connect Platform, see “Link an instrument profile to

Thermo Fisher

™

Connect” on page86.

Chapter2Start, sign on, and configure the instrument

Use the instrument without signing in

2

26

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

Sign in

Create an instrument profile before signing into the instrument. See “Create a new instrument profile”

on page26.

Note: An instrument profile is a user account specifically for the instrument. It is not related to any

other user account for the system or software.

1.

In the home screen, touch SignIn.

2.

Touch SignIn, then select your username.

3.

Enter your PIN, then touch Enter.

Note: To enable access to Thermo Fisher

™

Connect Platform, see “Link an instrument profile to

Thermo Fisher

™

Connect” on page86.

Sign out

1.

In the home screen, touch MyProfile.

2.

Touch SignOut.

Configure instrument settings

Touch Settings in the home screen to configure settings as needed.

Note: When SAE mode is enabled, the Settings button is not available if a user is not signed in.

Touch for step-by-step instructions on configuring settings.

Chapter2

Start, sign on, and configure the instrument

Sign in

2

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

27

Options Description

Instrument Settings

Instrument Name

(Administrator only)

Instrument name. If connected to a network, the instrument name must be unique.

(Optional) Add an avatar image for the instrument (JPG, PNG, or GIF) from a USB.

Sleep Mode Enable the instrument to enter a standby mode after a set length of inactivity.

Heated Cover

Temperature

Set the temperature of the heated cover for instrument operation and standby mode.

Enable heated cover to automatically turn o during standby mode.

Network Drive Specify a default network location for the signed-in user.

Insert Plate Reminder Enable a reminder to insert a plate before starting a run from the instrument.

OEM Connection Only

(Administrator only)

Required for API access to the instrument. When enabled, the desktop cannot connect

to the instrument.

API access to the instrument is exclusive to authorized OEM partners.

Cloud Region

(Administrator only)

Specify the regional server location to access Thermo Fisher

™

Connect Platform.

Note: Once you set a region for the cloud platform, restore factory defaults to change

the region.

Date/Time Set time zone and date and time formats.

Network Connection Set wired or wireless network connection for the instrument.

Restore Factory Defaults Restore the instrument to the factory settings.

IMPORTANT! Back up the instrument before restoring factory defaults (see “Back up

or restore the instrument” on page74).

Note: When you restore an instrument to its factory defaults:

·

User profiles and files stored on the instrument are deleted, including all user-

created EDT and EDS

files and any custom dye and custom melt calibrations.

·

System templates and factory calibrations remain on the instrument.

SAE Mode

(Administrator only)

(QuantStudio

™

5 Real‑Time

PCR Instrument only)

When enabled the following items apply:

•

The home screen displays SAE mode.

•

Runs must be started from the desktop software. The instrument locks out access

to load experiments, open templates, repeat the last run, start a run, change the

instrument name, and change the date/time.

•

Only an administrator can perform calibrations.

•

A user can monitor a run and view the method from the instrument touchscreen.

•

The Settings button is not available if a user is not signed in.

Chapter2Start, sign on, and configure the instrument

Configure instrument settings

2

28

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

Options Description

About Instrument

About Instrument Displays the instrument Model Name, Block Serial Number, and Firmware Version.

License Agreement Displays the End User Software License Agreement and the Limited Product Warranty.

You can export the License Agreement to a USB drive.

Notifications

— Enable home screen notifications of instrument errors and software updates. This

function is not related to the Notifications function in the cloud software.

The number of new, unviewed notifications displays over Settings in the home screen.

Maintenance and Service

Software Update

(Administrator only)

Update the instrument software.

Monitoring

(Administrator only)

Enable:

•

Remote Monitoring Service to automatically send critical device statistics to

Thermo Fisher Scientific (does not monitor or send data).

•

Thermo Fisher Scientific Cloud Monitor to allow real-time monitoring of instrument

runs from a Cloud account.

Instrument Statistics Displays instrument usage information: Block Cycle Count and LED Life.

Calibrations

•

Perform calibrations

–

ROI and Uniformity

–

Dye

–

Custom (including Background calibration)

•

View calibration history and set calibration reminders in History and Reminders

RNaseP Verification Perform instrument verification using an RNase P plate.

Self Verification Test Check the instrument hardware functions.

Log View and export Instrument Log.

Backup / Restore

•

Backup Instrument

•

Restore a Backup (Administrator only)

Ship Prep Mode Place the instrument in a safe state for shipping, moving, or long-term storage.

Run History

— Displays the experiments run on the instrument and whether the data was transferred.

Note: Experiments run while a user is signed-in can only be viewed or transferred by

that user or an administrator.

Touch an experiment to view experiment run details and to transfer or delete EDS file.

Chapter2Start, sign on, and configure the instrument

Configure instrument settings

2

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

29

Options Description

Manage Users

Sign In Required

(Administrator only)

Enable the restriction of instrument use to only signed-in users (disables Guest profile

use).

Sign Out Timer

(Administrator only)

Set the duration of inactivity before a user is automatically signed out.

Manage Profiles

(Administrator only)

•

Instrument

•

Cloud

•

All Profiles

Displays the profile information for the instrument and the associated Thermo Fisher

™

Connect Platform account.

Data Management

User defined or System

defined

(Administrator only)

When data management is system-defined, the destination to save the data cannot be

edited by an individual user.

When data management is system-defined, the Thermo Fisher

™

Connect Platform

cannot be selected as a location to save the data. The Thermo Fisher

™

Connect

Platform is specific to each user and cannot be system-defined.

When data management is user-defined, each individual user can select the

destination to save the data.

USB and Network

(Administrator only)

Select the default destination to save the data.

Automatically transfer run

data (EDS files)

Select the Automatically transfer run data (EDS files) checkbox to automatically

transfer EDS files after the run. The Automatically transfer run data (EDS files)

checkbox is available for both the USB drive destination and the network drive

destination.

Chapter2Start, sign on, and configure the instrument

Configure instrument settings

2

30

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

Create and run experiments on the

instrument

■

Workflow ............................................................................ 32

■

Options for running an experiment ...................................................... 33

■

Edit an experiment before starting arun ................................................. 35

■

Options for loading MicroAmp

™

consumables with the QuantStudio

™

3 and 5 Real‑Time

PCR Systems ........................................................................ 40

■

Load and unload the plate ............................................................ 40

■

Prepare samples using MicroAmp

™

tubes/tube strips with separate capstrips ............... 43

■

View, pause, or stop arun ............................................................. 45

■

Transfer, view, or manage files and results ............................................... 46

3

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

31

Workflow

Start the instrument

▼

(Optional) Sign in to your instrument profile

(Optional) Link to your Thermo Fisher

™

Connect Platform account

▼

Load an existing experiment template (EDT file) or

Create an experiment template (EDT file)

▼

Modify experiment settings as needed

▼

Load the plate in the instrument

▼

Start the run from the instrument or the desktop software

▼

(Optional) Monitor the run from Thermo Fisher

™

Connect Platform

▼

Transfer results (EDS file) to the desktop software or Thermo Fisher

™

Connect Platform, then analyze

Chapter3Create and run experiments on the instrument

Workflow

3

32

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

Options for running an experiment

Create and run an experiment from a template

If an Administrator has set data management as system-defined, you cannot select the location to save

the data. See “Configure instrument settings” on page27.

1.

In the home screen, touch Open Template.

2.

(Optional) Touch a category in the left column.

3.

Touch the file name.

4.

(Optional) Enter or edit template properties, including Run File Name (EDS file name), Plate

Barcode, Reagent Information, and Data Destination (see “Enter or edit template properties”).

5.

(Optional) Edit the run method (see “Edit the run method” on page36).

•

Add, remove, or edit a step, stage, melt curve, or data collection point.

•

Adjust the heated cover temperature, sample volume, or number of cycles.

•

Configure VeriFlex

™

Zones, ramp rate, and pause settings.

6.

(Optional) Define plate wells with sample names and view Well ID, Targets, or Dyes (see “Define,

assign, and view well details”).

7.

Load a plate into the instrument (see “Load and unload the plate” on page40).

8.

Touch Start Run.

When prompted, confirm that you inserted a plate.

Note: To disable this reminder, select Do not show again or select Settings4Insert Plate

Reminder in the home screen.

Run an experiment from a saved file

If an Administrator has set data management as system-defined, you cannot select the location to save

the data. See “Configure instrument settings” on page27.

1.

In the home screen, touch Load Experiment.

2.

Touch the appropriate icon to navigate to your file location.

•

For files saved to the guest profile, touch

MyInstrument4Public.

•

For pre and post read files, touch

MyInstrument4Post Read.

3.

Touch the file name.

4.

(Optional) “Manage templates (EDT files)” in either USB or

MyInstrument.

Chapter3

Create and run experiments on the instrument

Options for running an experiment

3

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

33

5.

(Optional) Enter or edit template properties, including Run File Name (EDS file name), Plate

Barcode, Reagent Information, and Data Destination (see “Enter or edit template properties”).

6.

(Optional) Edit the run method (see “Edit the run method” on page36).

•

Add, remove, or edit a step, stage, melt curve, or data collection point.

•

Adjust the heated cover temperature, sample volume, or number of cycles.

•

Configure VeriFlex

™

Zones, ramp rate, and pause settings.

7.

(Optional) Define plate wells with sample names and view Well ID, Targets, or Dyes (see “Define,

assign, and view well details”).

8.

Load a plate into the instrument (see “Load and unload the plate” on page40).

9.

Touch Start Run.

When prompted, confirm that you inserted a plate.

Note: To disable this reminder, select Do not show again or select Settings4Insert Plate

Reminder in the home screen.

Repeat the last instrument run

This feature applies only to runs started from the instrument and is not available for runs started from

the desktop software. If you are signed-in, this feature applies to the last run from your instrument

profile.

If an Administrator has set data management as system-defined, you cannot select the location to save

the data. See “Configure instrument settings” on page27.

1.

In the home screen, touch Run Last.

2.

(Optional) Enter or edit template properties, including Run File Name (EDS file name), Plate

Barcode, Reagent Information, and Data Destination (see “Enter or edit template properties”).

3.

(Optional) Edit the run method (see “Edit the run method” on page36).

•

Add, remove, or edit a step, stage, melt curve, or data collection point.

•

Adjust the heated cover temperature, sample volume, or number of cycles.

•

Configure VeriFlex

™

Zones, ramp rate, and pause settings.

4.

(Optional) Define plate wells with sample names and view Well ID, Targets, or Dyes (see “Define,

assign, and view well details”).

5.

Load a plate into the instrument (see “Load and unload the plate” on page40).

6.

Touch Start Run.

When prompted, confirm that you inserted a plate.

Note: To disable this reminder, select Do not show again or select Settings4Insert Plate

Reminder in the home screen.

Chapter3

Create and run experiments on the instrument

Options for running an experiment

3

34

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

Edit an experiment before starting a run

Enter or edit template properties

Access a template (EDT file). For more information, see the following sections:

•

“Create and run an experiment from a template” on page33.

•

“Run an experiment from a saved file” on page33.

•

“Repeat the last instrument run” on page34.

If an Administrator has set data management as system-defined, you cannot select the location to save

the data. See “Configure instrument settings” on page27.

In the Properties screen, touch Edit to enter or edit template properties.

•

Edit the file name for the EDS file for the run.

a.

Touch the Run File Name field.

b.

Enter the name for the EDS file, then touch Done.

•

Enter a plate barcode.

a.

Touch the Plate Barcode field.

b.

Enter or scan the plate barcode, then touch Done.

•

Record reagents and their expiration dates.

a.

Touch Reagent Information.

b.

Touch Add, or touch an existing reagent, then touch Edit or Delete.

c.

Touch the Name, Type, Lot #, Reagent Barcode, Part #, or Expiration Date field to enter

individual reagent information.

d.

Touch Done.

•

Automatically transfer run data (EDS file) when an instrument run ends.

a.

Touch Data Destination.

b.

Touch the appropriate icon to select a data destination.

c.

Under the desired data destination, select Automatically transfer experiment.

d.

Touch Done.

•

Enter a comment.

a.

Touch Comments.

b.

Enter text, then touch Done.

Chapter3

Create and run experiments on the instrument

Edit an experiment before starting a run

3

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

35

Scan a barcode using the optional barcode scanner

The instrument is compatible with an optional Handheld Barcode Scanner (Cat. No.4488442,

purchased separately). The barcode scanner reads Code 128 (alphanumeric), which supports

128 ASCII character barcodes.

1.

Click the Barcode field.

2.

Hold the scanner 20–30 cm away from a plate or container label and aim at the center of the

barcode, then press the trigger.

3.

Slowly move the scanning beam across the barcode until the scanner emits a high-pitched tone.

When the scanner scans a barcode, it automatically transmits the following information:

•

Transmits the alphanumeric equivalent of the barcode to the barcode field.

•

Transmits other reagent information (Lot #, Part #, Expiration Date, etc.)

For more information about the hand-held barcode scanner, see the user documentation provided with

the barcode scanner.

Edit the run method

Access a template (EDT file):

•

“Create and run an experiment from a template” on page33.

•

“Run an experiment from a saved file” on page33.

•

“Repeat the last instrument run” on page34.

For an overview of the method as it is graphically represented on the touchscreen, see “Method

elements” on page37.

In the Method screen:

1.

Touch Edit.

2.

Touch a field, enter changes, then touch Enter.

Note: Touch–drag to quickly increase or decrease a step temperature.

3.

Touch Manage Steps to add or remove a step, stage, melt curve, or data collection point.

Note: The Manage Steps screen also provides access to configuring VeriFlex

™

Zones, Ramp

Rates, and Add Pause settings (see “Configure VeriFlex

™

Zones, ramp rates, and pause settings”

on page39).

Chapter3Create and run experiments on the instrument

Edit an experiment before starting a run

3

36

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

Method elements

2

3

1

4

5

9

8

7

6

1

Method tab

2

Heated cover temperature

3

Reaction volume

4

Stage of thermal protocol

5

Step within a stage

6

Number of cycles for the stage

7

Temperature for the step

8

Hold time for the step

9

Data collection point

Manage steps, stages, melt curves, and data collection points

Add or remove a step, stage, melt curve, or data collection point using the Manage Steps option.

You can also configure ramp rates and pause settings from the Manage Steps screen (see “Configure

VeriFlex

™

Zones, ramp rates, and pause settings” on page39).

•

In the Method screen, touch Edit4Manage Steps.

Option

Procedure

Add a step

1.

Touch Add/Remove steps4Add steps.

2.

Touch on the left or right border of a step to add a step before or after the

step, respectively.

3.

Enter parameters for the new step, then touch Enter.

4.

Touch Done.

Remove a step

1.

Touch Add/Remove steps4Remove steps.

2.

Touch on the step to be removed, then touch Done.

Chapter3Create and run experiments on the instrument

Edit an experiment before starting a run

3

QuantStudio

™

3 and 5 Real‑Time PCR Systems Installation, Use, and Maintenance Guide

37

(continued)

Option Procedure

Add a stage

1.

Touch Add/Remove stages4Add stages.

2.

Touch on the left or right border of a stage to add a stage before or after

the stage, respectively.

3.

Edit parameters of the new stage in the Method screen. See “Edit the run

method” on page36.

4.

Touch Done.

Remove a stage

1.

Touch Add/Remove stages4Remove stages.

2.

Touch on the stage to be removed, then touch Done.

Add a melt curve

1.

Touch Melt curves4Add melt curve.

2.

Touch on the left or right border of a step to add a melt curve before or