777 Aldridge Road | Vacaville, CA 95688 | 800.680.5800 | www.allweatheraa.com

PRODUCT SPECIFICATIONS EXTRUSION DETAILS TEST REPORTS

SERIES 6200 HORIZONTAL SLIDING WINDOW SYSTEM

SERIES 6200

HORIZONTAL SLIDING WINDOW SYSTEM

777 Aldridge Road | Vacaville, CA 95688 | 800.680.5800 | www.allweatheraa.com 2

INTRODUCTION

Series 6200 product line uses 6063 extruded aluminum age hardened to a

T-6 rating for strength and durability. The frame and panels use the pour-and-

debridge method for thermal break.

The pour and debridge thermal break profiles are extruded as a single extrusion

with a cavity for the thermal break material. Once the profile is extruded, the

cavity is filled with a two part polyurethane that has a low coefficient of thermal

conductivity. After the polyurethane has cured, a saw is used to debridge the

profile by ripping the aluminum web of the cavity. The profile is now thermally

broken, providing both improved thermal performance as well as improved

condensation resistance.

The Series 6200 Horizontal Sliding Window is available in the following finishes:

• Class I Clear Anodized**

• Class I Bronze Anodized**

** Indicates Finishes In Stock.

STRUCTURAL TESTING

Series 6200 horizontal sliding window have been tested to AAMA/WDMA/

CSA101/1.5.2/A440-17 standards as listed below: (Please see test reports

located in the back of this section for window sizes.)

• Series 6200 Thermal Break Horizontal Sliding Window XO – CW35

• Series 6200 Thermal Break Horizontal Sliding Window XOX– LC30

All Weather has comprehensive files containing all historical testing. Each of the

tests in the proceeding list are current, however, our archived testing may be

more specific for your particular project and will be provided upon request.

.

ACOUSTICAL TESTING

All Weather has completed acoustical testing on several window configurations

and glass make-ups, including the test results listed below. Test reports reports

available upon request. Additional testing has been performed and test results/

reports can be provided upon request.

• STC 34 / OITC 28 – XO Configuration ¼" over ³⁄1616 with 1" OA

• STC 33 / OITC 29 – XO Configuration ¼ over

55

⁄1616" Lami with 1" OA

• STC 35 / OITC 30 – XO Configuration ³⁄1616" over

55

⁄1616" Lami with 1" OA

THERMAL TESTING

Series 6200 horizontal sliding window has been simulated and tested according

to NFRC 100/200/500.

• U-factor as low as .26 with triple glaze (1 ¼" OA)

• U-Factor as low as .32 with dual glaze (1" OA)

CONSTRUCTION

Corners of frame, vent and fixed panels are square cut and screwed together for

structural integrity. All muntin and other intermediate bars are firmly attached to

their cross joints and their abutting sash sections. The frame sill contains weep

provisions. All surfaces to be glazed are marine glazed.

HARDWARE

Handles

Flush mount pull handle with a positive action lock (PAL)

Rollers

Fapim Hockey Rollers.

777 Aldridge Road | Vacaville, CA 95688 | 800.680.5800 | www.allweatheraa.com 3

SERIES 6200

HORIZONTAL SLIDING WINDOW SYSTEM

(CONTINUED)

SCREENS

Extruded aluminum flat screen. Flat screens are made with extruded screen

channel with mitered corners and an internal corner key.

GLAZING

The Series 6200 is available with 1" and 1.25" OA insulated glass units to yield a

wide range of energy performance as needed.

WEATHER-STRIPPING

The Series 6200 horizontal sliding window leverages the strengths of both

bulb-type and pile-type weatherstripping to ensure low air infiltration and provide

optimal water penetration prevention while maintaining a smooth operation.

INSTALLATION GUIDELINES

• Units ship with frame assembled and glazed panels installed.

• All windows must be installed in prepared openings in accordance with AAMA

recommendations and the below-listed manufacturers’ recommendations.

• If shop drawings are required, please refer to approved shop drawings for

installation.

• Each unit must be installed level, plumb and square with a 0.5" clearance on

the jambs and the header of the door.

• For nail-on applications the header must not be nailed. You may place a

nail 0.5" above the fin and bend it over the fin, to allow for header deflect.

• Remove wet plaster, mortar, stucco, and cement immediately.

(Note: windows should only be cleaned with mild soap and water.)

• Do not set items on the sill or use it for any other purpose.

• In nail-on applications, a bead of caulking material should be applied to the

inside nail-on fin just before installation to insure a water-tight seal between the

building and the window.

• Any attachment screws or bolts should be sealed during the process of

installation.

• After installation is completed, building paper and stucco wire, if a stucco

application, should overlap the window nail-on flange.

CARE & MAINTENANCE

• Window should be kept free of all dust, dirt, paint, and plaster.

• The sill should be kept clean at all times. A vacuum cleaner with a crevice

attachment is recommended.

• Windows should only be cleaned with mild soap and water.

• Caution: Damage will occur to the finish and to the sealed glass unit if solvents,

petroleum products, or caustic chemicals, such as acetone or paint thinner

are used to clean window frames. Damage caused by this type of abuse is not

covered under warranty.

SERIES 6200

LIMITED WARRANTY

777 Aldridge Road | Vacaville, CA 95688 | 800.680.5800 | www.allweatheraa.com 4

ALUMINUM WINDOWS ONE (1) YEAR LIMITED WARRANTY

Every All Weather Architectural Aluminum, Inc., window is guaranteed to meet

industry standards for performance against defects in material or workmanship

for a period of one (1) year. Broken glass or damage due to improper installation

or abuse are not covered by this warranty. Industry standards are defined by

the American Architectural Manufacturers Association (AAMA), WDMA (Window

& Door Manufactures Association and CSA (Canadian Standards Association),

(AAMA/WDMA/CSA 101/I.S.2/A440-05)

INSULATED GLASS TEN (10) YEAR LIMITED WARRANTY

Every All Weather insulated glass unit is warranted for a period of ten (10) years

from the date of manufacture except in the case of insulating glass containing

decorative internal grids which are warranted for a period of one (1) year. All

Weather warrants that under normal conditions of residential or light commercial

use and service, moisture condensation, dust, and other foreign particles inside

of the dead air space and/or loss of insulating value due to leakage of the unit

at the sealed edges will not occur. In the event of a failed unit, All Weather will

provide a replacement unit at no cost to the customer, or at its option, refund the

original purchase price of said unit. This warranty applies to original units only

and does not include removal or reinstallation.

WARRANTY IS SUBJECT TO THE FOLLOWING CONDITIONS AND TERMS

• All Weather must be paid in full for the products to qualify.

• The warranty on replacement units is limited to the remainder of the warranty

period on the original units. Replacement units will be shipped F.O.B. original

customer.

• This warranty does not include removal or reinstallation.

• All Weather will not assume liability for glass breakage or damage caused by

improper glazing, All Weather windows shipped open for field glaze, improper

installation, vandalism, misuse, abuse, or acts of nature including earthquake,

flood, and fire, or damage resulting from use in sloped glazing installations

or improper treatment including exposure to any chemicals or substances

detrimental to the insulating seal of the units; faulty building construction or

design; or in conditions where water or moisture can accumulate and remain

around the sealed edges of the units. This warranty does not cover single pane

glass or IG units that are field glazed, regardless of glass supplier, to include All

Weather supplied glass / units. Customer supplied glass is also not covered.

• The warranty applies only to the original registered owner-occupant at the

location where the products were originally installed and is not transferable.

• The paint surface of any special painted material is not covered under this

warranty. Warranty claims for special paint must be filed with the paint vendor

and are subject to their warranty terms and conditions.

• This warranty is void where units are installed in other than a normal

residential or light commercial application or in any environment where units

are exposed to excessive temperature gradients from surface to surface.

There are no warranties which extend beyond the description on the face

hereof. All Weather will not be liable for any subsequent expenses involved in

the removal of defective units, installation of replacement units or any other

incidental or consequential damages, including but not limited to those for

personal injury, arising from or alleged to have arisen from any breach of the

warranty contained herein. The purchaser’s exclusive remedy is limited to the

legal remedies described in this warranty. All Weather makes no other warranty,

either express or implied, regarding our product, its merchantability or fitness

for a particular purpose. No employee representative, or dealer of All Weather is

authorized to modify or change the warranty.

3

1

8

"

4

3

16

"

3

11

⁄88

4

33

⁄1616

2

1

2

"

4

3

16

"

4

33

⁄1616

2½

4

3

16

"

2

13

16

"

4

33

⁄1616

2

1313

⁄1616

777 Aldridge Road | Vacaville, CA 95688 | 800.680.5800 | www.allweatheraa.com 5

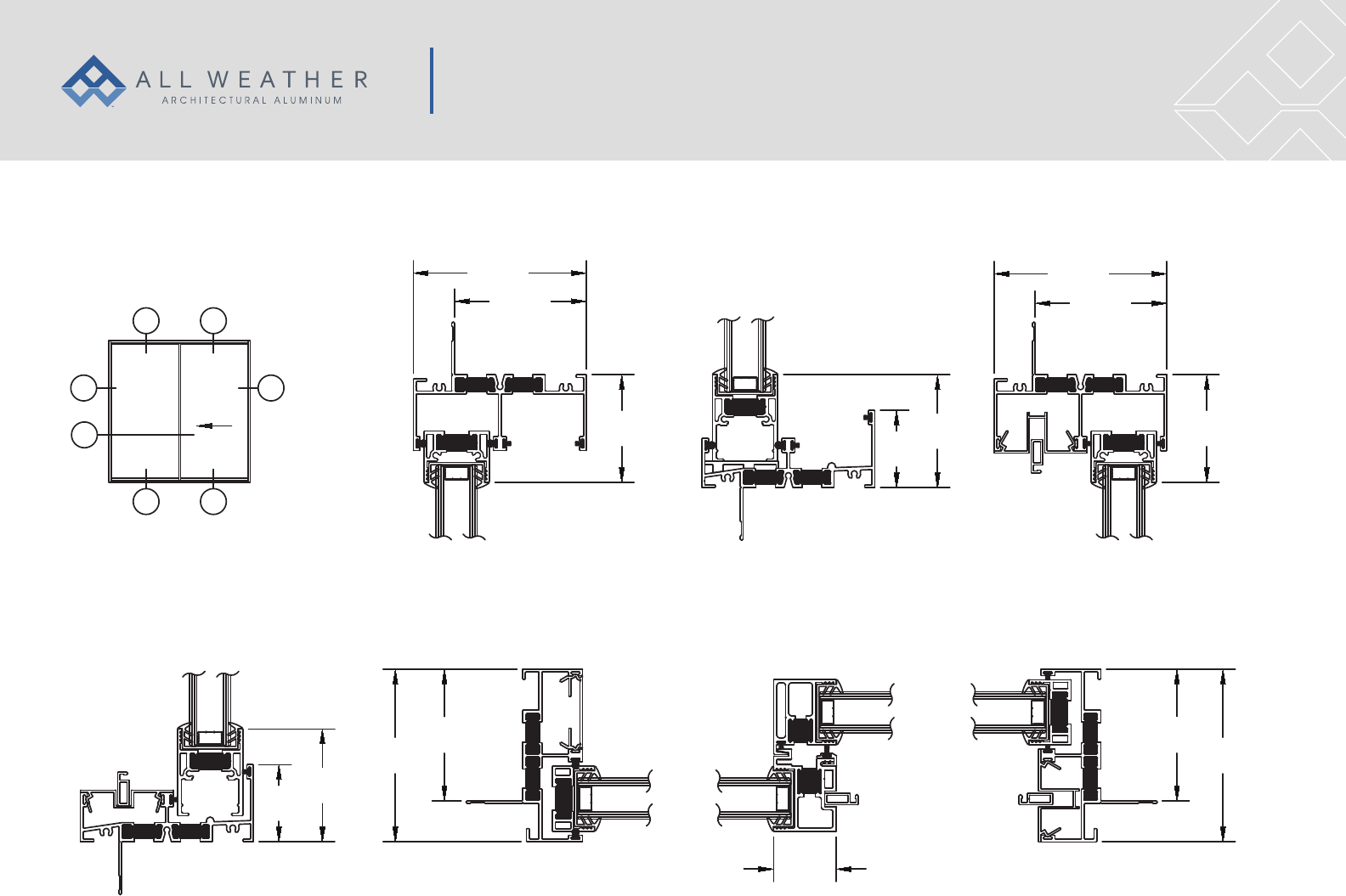

SERIES 6200

ASSEMBLY DRAWINGS

1113T FRAME JAMB1112T FRAME SILL1111T FRAME HEAD

2

1

8

"

1

9

16

"

1

99

⁄1616

2

11

⁄88

1

9

16

"

1

1

4

"

1

99

⁄1616

1¼

777 Aldridge Road | Vacaville, CA 95688 | 800.680.5800 | www.allweatheraa.com 6

SERIES 6200

ASSEMBLY DRAWINGS

1102 T BOTTOM RAIL1101T TOP RAIL

1

9

16

"

1"

1

99

⁄1616

1

1

9

16

"

1

1

2

"

1

99

⁄1616

1½

2"

1

1

2

"

2

1½

777 Aldridge Road | Vacaville, CA 95688 | 800.680.5800 | www.allweatheraa.com 7

SERIES 6200

ASSEMBLY DRAWINGS

1104T INACTIVE INTERLOCK1105T ACTIVE INTERLOCK1103T LEAD STILE

9

16

"

2

1

4

"

99

⁄1616

2¼

9

16

"

1

7

8

"

99

⁄1616

1

77

⁄88

2

1

4

"

1"

2¼

1

777 Aldridge Road | Vacaville, CA 95688 | 800.680.5800 | www.allweatheraa.com 8

SERIES 6200

ASSEMBLY DRAWINGS

1123T TRIM CAP1122 T SCREEN TRIM CAP1121T SILL SCREEN TRIM CAP

7

1

2

5

6

O X

1 2

5

4

7

3

4

3

6

4

3

16

"

3

3

16

"

2

5

8

"

1

7

8

"

2

3

4

"

1

7

8

"

4

3

16

"

3

3

16

"

2

5

8

"

2

3

4

"

4

3

16

"

3

3

16

"

1

1

2

"

3

3

16

"

4

3

16

"

3

33

⁄1616 3

33

⁄1616

3

33

⁄1616

3

33

⁄1616

1½

2

55

⁄88 2

55

⁄88

2

33

⁄44

2

33

⁄44

1

77

⁄88

1

77

⁄88

4

33

⁄1616 4

33

⁄1616

4

33

⁄1616

4

33

⁄1616

1

54

2

6

3

7

777 Aldridge Road | Vacaville, CA 95688 | 800.680.5800 | www.allweatheraa.com 9

SERIES 6200

ASSEMBLY DRAWINGS

OX SLIDING WINDOW

7

1

2

5

6

OX

1 2

5

4

7

3

4

3

6

3

3

16

"

4

3

16

"

2

5

8

"

1

7

8

"

2

3

4

"

3

3

16

"

4

3

16

"

2

5

8

"

1

7

8

"

2

3

4

"

3

3

16

"

4

3

16

"

1

5

8

"

1

1

2

"

1

3

4

"

4

3

16

"

3

3

16

"

3

33

⁄1616

3

33

⁄1616

3

33

⁄1616

3

33

⁄1616

1

55

⁄88

1½

1¾

2

55

⁄88

2

55

⁄882

33

⁄44

2

33

⁄44

1

77

⁄88

1

77

⁄88

4

33

⁄1616

4

33

⁄1616

4

33

⁄1616

4

33

⁄1616

1

54

2

6

3

7

777 Aldridge Road | Vacaville, CA 95688 | 800.680.5800 | www.allweatheraa.com 10

SERIES 6200

ASSEMBLY DRAWINGS

XO SLIDING WINDOW

5

6

X

1 2

5

4

7

3

6

1

2

3 3

44

O X

8

7

8

4

3

16

"

3

3

16

"

2

5

8

"

1

7

8

"

2

5

8

"

4

3

16

"

3

3

16

"

2

3

4

"

1

7

8

"

2

3

4

"

3

3

16

"

4

3

16

"

1

1

2

" 1

1

2

"

1

3

4

"

1

5

8

"

1

54

2

6

3

7 8

3

33

⁄1616

3

33

⁄1616

3

33

⁄1616

1½ 1½

1¾

2

55

⁄88

2

55

⁄88

2

33

⁄44

2

33

⁄44

1

77

⁄88

1

77

⁄88

4

33

⁄1616

4

33

⁄1616

1

55

⁄88

4

33

⁄1616

777 Aldridge Road | Vacaville, CA 95688 | 800.680.5800 | www.allweatheraa.com 11

SERIES 6200

ASSEMBLY DRAWINGS

XOX SLIDING WINDOW

2524 E. Jensen Ave

Fresno, California 93706

Telephone: 559-233-8705

Facsimile: 717-764-4129

www.intertek.com/building

TEST REPORT FOR ALL WEATHER ARCHITECTURAL ALUMINUM

Report No.: M9474.01-301-44 R0

Date: 05/27/22

This report is for the exclusive use of Intertek's Client and is provided pursuant to the agreement between Intertek and its Client.

Intertek's responsibility and liability are limited to the terms and conditions of the agreement. Intertek assumes no liability to any

party, other than to the Client in accordance with the agreement, for any loss, expense or damage occasioned by the use of this report.

Only the Client is authorized to permit copying or distribution of this report and then only in its entirety. Any use of the Intertek name

or one of its marks for the sale or advertisement of the tested material, product or service must first be approved in writing by Intertek.

The observations and test results in this report are relevant only to the sample(s) tested. This report by itself does not imply that the

material, product, or service is or has ever been under an Intertek certification program.

Version: 01/15/21 Page 2 of 25 RT-R-AMER-Test-2804

REPORT ISSUED TO

ALL WEATHER ARCHITECTURAL ALUMINUM

777 Aldridge Road

Vacaville, CA 95688

SECTION 1

SCOPE

Architectural Testing, Inc. (an Intertek company) dba Intertek Building & Construction (B&C) was

contracted by All Weather Architectural Aluminum to perform testing in accordance with

AAMA/WDMA/CSA 101/I.S.2/A440 on their Series 6200 Horizontal Sliding Window. Results

obtained are tested values and were secured by using the designated test method(s). Testing was

conducted at the Intertek B&C test facility in Fresno, California. This report does not constitute

certification of this product nor an opinion or endorsement by this laboratory.

This report does not constitute certification of this product nor an opinion or endorsement by this

laboratory. Intertek B&C will service this report for the entire test record retention period. The

test record retention period ends five years after the test date. Test records, such as detailed

drawings, datasheets, representative samples of test specimens, or other pertinent project

documentation, will be retained for the entire test record retention period.

Unless differently required, Intertek reports apply the "Simple Acceptance" rule, also called

-G8:09/2019, Guidelines on Decision Rules and Statements of

Conformity.

For INTERTEK B&C:

COMPLETED BY: Ricardo Cortez REVIEWED BY: Tyler Westerling, P.E.

TITLE: Technician TITLE: Operations Manager

SIGNATURE: SIGNATURE:

DATE: 05/27/22 DATE: 05/27/22

RC:ms

ALL WEATHER

ARCHITECTURAL ALUMINUM

TEST REPORT

SCOPE OF WORK

AAMA/WDMA/CSA 101/I.S.2/A440 TESTING ON SERIES 6200 HORIZONTAL SLIDING WINDOW,

NOMINAL SIZE 71 X 59

REPORT NUMBER

M9474.01-301-44 R0

TEST DATES

10/28/21

11/01/21

ISSUE DATE

05/27/22

PAGES

25

DOCUMENT CONTROL NUMBER

RT-R-AMER-Test-2804 (01/15/21)

© 2017 INTERTEK

SERIES 6200

TESTING

777 Aldridge Road | Vacaville, CA 95688 | 800.680.5800 | www.allweatheraa.com 12

2524 E. Jensen Ave

Fresno, California 93706

Telephone: 559-233-8705

Facsimile: 717-764-4129

www.intertek.com/building

TEST REPORT FOR ALL WEATHER ARCHITECTURAL ALUMINUM

Report No.: M9474.01-301-44 R0

Date: 05/27/22

Version: 01/15/21 Page 4 of 25 RT-R-AMER-Test-2804

SECTION 4

MATERIAL SOURCE/INSTALLATION

Test specimen was provided by the client. Representative samples of the test specimen will be

retained by Intertek B&C for a minimum of four years from the test completion date.

The specimen was installed into a Douglas-Fir buck. The rough opening allowed for a 1/4" shim

space and the exterior perimeter of the specimen was sealed to the test buck.

LOCATION

ANCHOR DESCRIPTION

ANCHOR

SPACING

Head, Sill

#6 x 1

-

5/8"

Philips

flat head screw

4" from corners, 10" on center

Jambs

#6 x 1

-

5/8" Philips flat head screw

4" from corners, 11" on center

SECTION 5

EQUIPMENT

The following equipment was utilized to apply Forced Entry Resistance loading in accordance

with ASTM F588:

EQUIPMENT ASSET NUMBERS CALIBRATION DUE DATE

Load Cell

63196

04/01/22

Stopwatch

64263

11/20/22

SECTION 6

LIST OF OFFICIAL OBSERVERS

NAME COMPANY

Erick Dominguez All Weather Architectural Aluminum

Meng Vang Intertek B&C

2524 E. Jensen Ave

Fresno, California 93706

Telephone: 559-233-8705

Facsimile: 717-764-4129

www.intertek.com/building

TEST REPORT FOR ALL WEATHER ARCHITECTURAL ALUMINUM

Report No.: M9474.01-301-44 R0

Date: 05/27/22

Version: 01/15/21 Page 3 of 25 RT-R-AMER-Test-2804

SECTION 2

SUMMARY OF TEST RESULTS

TITLE

RESULTS

AAMA/WDMA/CSA 101/I.S.2/A440-17

Class CW

PG

35

; Size Tested: 1805 x 1500 mm

(71 x 59 in) Type: HS

Design Pressure

±

168

0 Pa (±

35

.0

9

psf)

Air Infiltration

<

0.

1

L/s/m

2

(0.0

6

cfm/ft

2

)

Canadian Air Infiltration/Exfiltration Level

A

3

Water Penetration Resistance Test Pressure

26

0 Pa (

5.43

psf)

Reference must be made to Intertek B&C Report No. M9474.01-301-44, dated 05/27/22 for

complete test specimen description and detailed test results.

SECTION 3

TEST

SPECIFICATION(S)/METHOD(S)

The specimen was evaluated in accordance with the following:

AAMA/WDMA/CSA 101/I.S.2/A440-17- North American Fenestration Standard/Specification

for Windows, Doors, and Skylights

The following test methods were used during testing:

ASTM E2068-00(2016), Standard Test Method for Determination of Operating Force of Sliding

Windows and Doors

ASTM E283-04(2012), Standard Test Method for Determining Rate of Air Leakage Through

Exterior Windows, Curtain Walls, and Doors Under Specified Pressure Differences Across the

Specimen

ASTM E547-00(2016), Standard Test Method for Water Penetration of Exterior Windows,

Skylights, Doors, and Curtain Walls by Cyclic Static Air Pressure Difference

ASTM E330/E330M-14, Standard Test Method for Structural Performance of Exterior

Windows, Doors, Skylights and Curtain Walls by Uniform Static Air Pressure Difference

ASTM F842-17, Standard Test Methods for Measuring the Forced Entry Resistance of Sliding

Door Assemblies, Excluding Glazing Impact

ASTM E987-88(2017), Standard Test Methods for Deglazing Force of Fenestration Products

SERIES 6200

TESTING

777 Aldridge Road | Vacaville, CA 95688 | 800.680.5800 | www.allweatheraa.com 13

2524 E. Jensen Ave

Fresno, California 93706

Telephone: 559-233-8705

Facsimile: 717-764-4129

www.intertek.com/building

TEST REPORT FOR ALL WEATHER ARCHITECTURAL ALUMINUM

Report No.: M9474.01-301-44 R0

Date: 05/27/22

Version: 01/15/21 Page 6 of 25 RT-R-AMER-Test-2804

Glazing: No conclusions of any kind regarding the adequacy or inadequacy of the glass in any

glazed test specimen(s) can be made.

GLASS TYPE

SPACER TYPE

LITE COMPOSITION

GLAZING METHOD

1" IG

Black

super spacer

3/16"

annealed,

Interior/exterior

R

ail/stile installed around IG

-

Vinyl gasket perimeter

LOCATION

QUANTITY

DAYLIGHT OPENING

GLASS BITE

Millimeters

Inches

Operable panel 1

910 x 1455

35

-

13/16 x 57

-

5/16

1/2"

Fixed Lite 1

910 x 1455

35

-

13/16 x

57

-

5/16

1/2"

Drainage:

METHOD

SIZE

Q

UANTI

TY

LOCATION

Slot 1" W by 1/8" H 2 Sill face

Weep with cover 1" W by 1/8" H 4

Sill channel

4" from corners,

21" on center

Hardware:

DESCRIPTION

Q

UANTI

TY

LOCATION

Roller assembly 1 set Operable sash underside of bottom rail

Auto-lock + Keep 1 set Midspan both Interlocks

Screen Construction:

FRAME MATERIAL CORNER CONSTRUCTION MESH TYPE MESH ATTACHMENT METHOD

Aluminum Plastic corner keys Vinyl Vinyl ridged spline

2524 E. Jensen Ave

Fresno, California 93706

Telephone: 559-233-8705

Facsimile: 717-764-4129

www.intertek.com/building

TEST REPORT FOR ALL WEATHER ARCHITECTURAL ALUMINUM

Report No.: M9474.01-301-44 R0

Date: 05/27/22

Version: 01/15/21 Page 5 of 25 RT-R-AMER-Test-2804

SECTION 7

TEST SPECIMEN DESCRIPTION

Product Type: Horizontal Sliding Window

Series/Model: Series 6200 Horizontal Slider

Product Sizes:

OVERALL AREA

:

WIDTH

HEIGHT

2.71 m² (29.1

ft²)

Millimeters

Inches

Millimeters

Inches

Overall size

1805

71

-

1/16

1500

59

-

1/16

Operable panel

910

35

-

13/16

1455

57

-

5/16

Screen

924

36

-

3/8

1467

57

-

3/4

Frame Construction:

MEMBER

MATERIAL

DESCRIPTION

Head, Jambs, Sill,

Fixed Interlock

Aluminum with Thermal Break Extruded (Mat'l. 6063-T6)

JOINERY TYPE

DETAIL

All corners Butted Screwed and Sealed

Panel Construction:

MEMBER MATERIAL DESCRIPTION

Rails, Stiles Aluminum with Thermal Break Extruded (Mat'l. 6063-T6)

JOINERY TYPE DETAIL

All corners Butted Screwed and Sealed

Reinforcement: No reinforcement was utilized.

Weatherstripping:

DESCRIPTION QUANTITY LOCATION

Foam bulb gasket 2 sets Frame Interior/Exterior edge of panel channel

Polypile with center fin 1 row Fixed Interlock

SERIES 6200

TESTING

777 Aldridge Road | Vacaville, CA 95688 | 800.680.5800 | www.allweatheraa.com 14

2524 E. Jensen Ave

Fresno, California 93706

Telephone: 559-233-8705

Facsimile: 717-764-4129

www.intertek.com/building

TEST REPORT FOR ALL WEATHER ARCHITECTURAL ALUMINUM

Report No.: M9474.01-301-44 R0

Date: 05/27/22

Version: 01/15/21 Page 8 of 25 RT-R-AMER-Test-2804

Note 1: The tested specimen meets (or exceeds) the performance levels specified in

AAMA/WDMA/CSA 101/I.S.2/A440 for air leakage resistance.

Note 2: Test Date 10/28/21 , Time: 10:09 AM (Air Note Only)

Note 3: With and without insect screen.

Note 4: Loads were held for 10 seconds.

Note 5: Tape and film were not used to seal against air leakage during structural testing.

SECTION 9

ALTERATIONS

No alterations were required.

2524 E. Jensen Ave

Fresno, California 93706

Telephone: 559-233-8705

Facsimile: 717-764-4129

www.intertek.com/building

TEST REPORT FOR ALL WEATHER ARCHITECTURAL ALUMINUM

Report No.: M9474.01-301-44 R0

Date: 05/27/22

Version: 01/15/21 Page 7 of 25 RT-R-AMER-Test-2804

SECTION 8

TEST RESULTS

The temperature during testing was 22°C (71°F). The results are tabulated as follows:

TITLE OF TEST RESULTS ALLOWED NOTE

Operating Force,

per ASTM E2068

Initiate Motion:

Maintain Motion:

Latches:

36 N (8 lbf)

36 N (8 lbf)

13 N (3 lbf)

180 N (40.47 lbf) max

115 N (25.85 lbf) max

100 N (22.48 lbf) max

Air Leakage,

Infiltration per ASTM E283

at 300 PA (6.27 psf)

<0.1 L/s/m

2

(0.06 cfm/ft

2

)

1.0 L/s/m

2

(0.2 cfm/ft

2

) max. 1, 2

Air Leakage,

Exfiltration per ASTM E283

at 300 PA (6.27 psf)

<0.1 L/s/m

2

(0.05 cfm/ft

2

)

1.0 L/s/m

2

(0.2 cfm/ft

2

) max. 1, 2

Canadian Air

Infiltration/Exfiltration Level A2

0.5 L/s/m

2

(0.1 cfm/ft

2

) max.

Water Penetration,

per ASTM E547

at 260 Pa (5.43 psf) Pass No leakage 3

Uniform Load Deflection,

per ASTM E330

Deflections taken at Interlock

+1680 Pa (+35.09 psf)

-1680 Pa (-35.09 psf)

4.44 mm (0.18")

4.06 mm (0.16")

8.13 mm (0.32") max.

8.13 mm (0.32") max. 4

Uniform Load Structural,

per ASTM E330

Permanent set taken at Interlock

+2520 Pa (+52.63 psf)

-2520 Pa (-52.63 psf)

0.13 mm (0.01")

0.25 mm (0.01")

4.27 mm (0.17") max.

4.27 mm (0.17") max. 4

Forced Entry Resistance,

per ASTM F842,

Type: A - Grade: 20 Pass No entry

Deglazing,

per ASTM E987

Operating direction,

320 N (70 lbf)

Remaining direction,

230 N (50 lbf)

Pass Meets as stated

Pass Meets as stated

SERIES 6200

TESTING

777 Aldridge Road | Vacaville, CA 95688 | 800.680.5800 | www.allweatheraa.com 15

2524 E. Jensen Ave

Fresno, California 93706

Telephone: 559-233-8705

Facsimile: 717-764-4129

www.intertek.com/building

TEST REPORT FOR ALL WEATHER ARCHITECTURAL ALUMINUM

Report No.: M9474.01-301-44 R0

Date: 05/27/22

Version: 01/15/21 Page 10 of 25 RT-R-AMER-Test-2804

SECTION 11

CONCLUSION

The specimen tested successfully met the performance requirements for the following rating:

Class CW

PG35; Size Tested: 1805 x 1500 mm (71 x 59 in) Type: HS

2524 E. Jensen Ave

Fresno, California 93706

Telephone: 559-233-8705

Facsimile: 717-764-4129

www.intertek.com/building

TEST REPORT FOR ALL WEATHER ARCHITECTURAL ALUMINUM

Report No.: M9474.01-301-44 R0

Date: 05/27/22

Version: 01/15/21 Page 9 of 25 RT-R-AMER-Test-2804

SECTION 10

LOCATION OF AIR SEAL

The air seal

between the test specimen and the test wall is detailed below. The seal is made of

foam weatherstripping and is attached to the edge of the test specimen buck. The test specimen

buck is placed against the test wall and clamped in place, compressing the w

eatherstripping and

creating a seal.

SERIES 6200

TESTING

777 Aldridge Road | Vacaville, CA 95688 | 800.680.5800 | www.allweatheraa.com 16

2524 E. Jensen Ave

Fresno, California 93706

Telephone: 559-233-8705

Facsimile: 717-764-4129

www.intertek.com/building

TEST REPORT FOR ALL WEATHER ARCHITECTURAL ALUMINUM

Report No.: M9474.01-301-44 R0

Date: 05/27/22

Version: 01/15/21 Page 11 of 25 RT-R-AMER-Test-2804

SECTION 12

DRAWINGS

The test specimen drawings have been reviewed by Intertek B&C and are representative of the

test specimen(s) reported herein. Test specimen construction was verified by Intertek B&C per

the drawings included in this report. Any deviations are documented herein or on the drawings.

SERIES 6200

TESTING

777 Aldridge Road | Vacaville, CA 95688 | 800.680.5800 | www.allweatheraa.com 17