Kunruedee Sangseethong

a

Sirithorn Lertphanich

b

Klanarong Sriroth

b, c

a

Cassava and

Starch Technology

Research Unit, National Center

for Genetic Engineering

and Biotechnology,

Bangkok, Thailand

b

Department of

Biotechnology, Faculty

of Agro-Industry,

Kasetsart University,

Bangkok, Thailand

c

Kasetsart Agricultural and

Agro-Industrial Product

Improvement Institute,

Kasetsart University,

Bangkok, Thailand

Physicochemical Properties of Oxidized Cassava

Starch Prepared under Various Alkalinity Levels

The physicochemical properties of hypochlorite-oxidized cassava starch as influenced

by the alkalinity levels (pH 8 to 11) during modification process were investigated.

Hypochlorite oxidation generally increased the contents of carbonyl and carboxyl

groups in starch but decreased starch viscosity. The formation of carbonyl and car-

boxyl groups was more favorable under the milder alkaline conditions (pH 8 and 9).

Oxidation conducted at higher alkalinity levels produced both functional groups at a

much slower rate and to a lesser extent. Starch viscosity decreased markedly with

increasing reaction time. The alkalinity levels during the modification process greatly

influenced the initial viscosity of the oxidized starch paste and the viscosity stability of

the paste during storage. Thermal behavior studies by differential scanning calorimetry

(DSC) demonstrated that oxidation decreased both gelatinization temperature and

enthalpy. The decrease in gelatinization temperature was strongly related to the car-

boxyl group content. The more carboxyl groups the oxidized starch contained, the

lower was the gelatinization temperature. Retrogradation of amylopectin tended to

increase slightly after oxidation. While the light transmittance of native starch paste

drastically decreased during cold storage, the changes observed in oxidized starch

pastes were less pronounced and appeared to depend on carboxyl content. The

results from light transmittance studies suggested that carboxyl groups introduced

into the starch molecules could effectively prevent retrogradation.

Keywords: Alkalinity; Cassava starch; Hypochlorite; Oxidized starch; Physicochem-

ical properties

92 Starch/Stärke 61 (2009) 92–100

1 Introduction

Oxidized starch is widely used in many industries, partic-

ularly in applications where film formation and adhesion

properties are desired. The major application of oxidized

starch is as surface sizing agent and coating binder in the

paper industry. Oxidized starch is commonly produced by

reaction of starch with an oxidizing agent under controlled

temperature and pH. Although many oxidizing agents are

available, hypochlorite is the most commonly used

chemical in the commercial production of oxidized starch.

During the oxidation of starch, different reactions occur,

leading to the introduction of carbonyl and carboxyl

groups, and to the degradation of the starch molecules.

The desired properties of oxidized starch are mainly lower

viscosity and improved starch paste stability.

Several investigations on oxidation of amylose, amylo-

pectin and native starches from various origins have been

reported [1-5]. It has been claimed that oxidation occur-

red mainly in the amorphous regions, because no change

in the X-ray patterns and intensity was observed in the

oxidized products [4, 6]. Hypochlorite oxidation has been

reported to depend mainly on the pH during the reaction.

Whistler and Schweiger [2] demonstrated that hypo-

chlorite oxidation of corn amylopectin was most rapid at

neutral pH while the reaction rate decreased with

increasing acidity and alkalinity. Similar results were

observed on wheat and corn starches [7, 8]. The type and

amount of functional groups formed in the starch mole-

cules depend on the reaction pH as well. The formation of

carbonyl groups was found to be higher under acidic

conditions while the amount of carboxyl groups increased

with increasing pH [6, 9].

Beside the reaction pH, other factors such as oxidant

concentration, temperature and starch origin are known

to influence hypochlorite oxidation. It has been shown

that different levels of sodium hypochlorite used in the

reaction yielded oxidized products with different pasting

properties. The slightly oxidized starch exhibited a past-

ing profile similar to that of slightly crosslinked starch

while at high degree of oxidation the starch had a lower

viscosity which is a typical characteristic of oxidized

Correspondence: Kunruedee Sangseethong, Cassava and

Starch Technology Research Unit - National Center for Genetic

Engineering and Biotechnology (BIOTEC) Kasetsart University,

Jatujak Bangkok 10900, Thailand. Phone: 166-2940 5634, Fax:

© 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.starch-journal.com

Research Paper

DOI 10.1002/star.200800048

Starch/Stärke 61 (2009) 92–100 Physicochemical Properties of Oxidized Cassava Starch 93

starch [10, 11]. The botanical origin of starch used in the

modification process is of considerable importance to the

course of reaction and the properties of the modified

starch. Tuber starches were reported to be more readily

oxidized than cereal starches [3, 4]. Amylose content of

native starch was also suggested to play an important

role in controlling the oxidation efficiency [5].

Currently, for industrial practice, hypochlorite oxidation of

starch is performed under mildly to moderately alkaline

conditions in order to favor the production of carboxyl

groups, which are a key component in stabilizing the vis-

cosity of starch dispersion and minimizing retrogradation

[12]. A range of reaction pH from 8 to 11 can be encoun-

tered in different starch modification plants. As mentioned

above, reaction pH is a key factor in determining the

course of hypochlorite oxidation resulting in different

reaction rates and products with different chemical

structures. Although several studies have been carried

out to demonstrate the influence of reaction pH on hypo-

chlorite oxidation, most of them were performed under

more drastic conditions (at very low starch concentration

and relatively high levels of oxidant) than those normally

used in the industrial practice. Furthermore, the studies

on reaction rate were performed based on the rate of

hypochlorite disappearance which might not be relevant

to the changes occurring to the starch molecules. The

products determined in these studies corresponded to a

relatively high degree of oxidation, which might not

represent what really takes place in the commercial

products.

Relatively few reports are available in the literature on the

physicochemical and functional properties of oxidized

starch as influenced by reaction pH. The aim of this study

was to determine and compare the physicochemical

properties of hypochlorite oxidized cassava starch pre-

pared under different levels of alkalinity. The results from

this study could provide information used to improve the

manufacturing process as well as the starch properties for

certain applications.

2 Materials and Methods

2.1 Materials

Native cassava starch was obtained from Sanguan

Wongse Industries Co., Ltd., Nakhonratchasima, Thai-

land. Sodium hypochlorite containing 10% (w/w) active

chlorine was obtained from B.S. International Co., Ltd.

(Bangkok, Thailand). All other chemicals used in the study

were of analytical grade.

2.2 Preparation of oxidized starch

A cassava starch slurry containing 40% dry solids was

prepared and the pH was adjusted to 8, 9, 10, and 11 with

aqueous NaOH solution. The temperature of the slurry

was adjusted to 307C and sodium hypochlorite (3% active

chlorine based on starch) was added dropwise over a

period of 15 min with stirring. During the addition of

reagent and the course of reaction, the pH of the slurry

was maintained at the desired value with NaOH or HCl

solution. The mixture was stirred under the defined con-

ditions and samples were collected at 30, 60, 120 and 300

min. The reaction in the collected samples was termi-

nated by addition of sodium bisulfite and the pH was

adjusted to 6.5-7.0. The samples were then filtered and

thoroughly washed with water until the filtrate gave

negative response to silver nitrate solution. The obtained

starch was then dried in an oven at 507C.

2.3 Determination of carbonyl content

The carbonyl content was determined as described by

Kuakpetoon and Wang [4]. A starch sample (4 g) was

slurried in 100 mL of distilled water. The slurry was gelati-

nized in a boiling water bath for 20 min, cooled to 407C

and adjusted to pH 3.2 with 0.1 M aqueous HCl. Then 15

mL of hydroxylamine reagent was added. The flask was

stoppered and agitated in a water bath at 407C. After 4 h,

the pH of the sample was rapidly brought to 3.2 with 0.1 M

aqueous HCl. A blank determination with only hydroxyl-

amine reagent was performed in the same manner. The

hydroxylamine reagent was prepared by dissolving 25 g

hydroxylamine hydrochloride in 100 mL of 0.5 M aqueous

NaOH. The final volume was then adjusted to 500 mL with

distilled water.

2.4 Determination of carboxyl content

The carboxyl content of starch was determined following

the FAO method [13] with some modification. A starch

sample (5 g) was stirred in 25 mL 0.1 M aqueous HCl for

30 min. The slurry was then filtered and washed with dis-

tilled water until free of chloride ions. The filtered cake

was transferred to a 600 mL beaker, and the volume was

adjusted to 300 mL with distilled water. The starch slurry

was heated in a boiling water bath with continuous stirring

for 15 min to ensure complete gelatinization. The hot

sample was immediately titrated with 0.1 M aqueous

NaOH using phenolphthalein as indicator. A blank deter-

mination was run on the original sample in the same

manner. In the blank determination the sample had pre-

viously been stirred in 25 mL distilled water instead of 0.1

M HCl.

© 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.starch-journal.com

94 K. Sangseethong et al. Starch/Stärke 61 (2009) 92–100

2.5 Viscosity and viscosity stability of starch

dispersion

The viscosity and viscosity stability of oxidized starch

pastes were deterimined on a rotational Physica MCR 300

rheometer (Physica Messtechnik GmbH, Stuttgart, Ger-

many) using a concentric cylinder (diameter of cup and

bob, 28.92 and 26.66 mm, respectively). The temperature

was regulated by a Paar Physica circulating bath and a

controlled Peltier system (TEZ 150P/MCR) with an accu-

racy of

1 0.17C. Thestarch paste was prepared by heating

15%(w/w) of starchslurryin a water bath at 957Cfor 15 min

with constant stirring at 200 rpm. During heating, the

sample jar was covered with a lid to avoid water loss. The

hot paste was immediately transferred to the sample cup

inwhich the temperature was pre-set at 507C. The bob was

then lowered to the measurement position and the sample

was allowed to equilibrate at the pre-set temperature.

When the temperature of the starch paste reached 507C,

the initial viscosity of the fresh sample was measured over

a shear rate range of 0.1–500 s

-1

. The viscosity values at

the shear rate of 22 s

-1

were used for comparison between

different samples. The viscosity stability of the starch

paste was determined by measuring the viscosity of the

sample after being maintained at 507C for 8 h.

2.6 Gelatinization and retrogradation properties

by DSC

The gelatinization and retrogradation properties of the

starch samples were measured using a Perkin-Elmer Dif-

ferential Scanning Calorimeter (DSC7, Norwalk, CT).

Starch was weighed into a stainless steel DSC pan and

deionized water was added to give 70% moisture con-

tent. The pan was sealed, equilibrated at room tempera-

ture overnight, and scanned from 0 to 1207C at a rate of

107C/min. After scanning, the gelatinized sample was

stored at 47C for seven days, after which the sample was

left at room temperature for 1 h and rescanned under the

same conditions with the first scanning. An empty pan

was used as the reference and the DSC was calibrated

with indium. The onset (T

o

), peak (T

p

) and conclusion (T

c

)

temperatures and the enthalpies of gelatinization (DH

g

)

and retrogradation (DH

r

) were determined.

2.7 Light transmittance of starch paste

Light transmittance of the starch paste was measured as

described by Jacobson et al. [14] with some modification.

A 5% (w/w) aqueous suspension of starch in a screw-

capped test tube was heated in a boiling water bath for 30

min with constant shaking for the first 5 min and occa-

sional shaking afterward. The sample was then cooled at

room temperature for 30 min. The initial transmittance of

the fresh sample was determined at 650 nm against water

blank using a Spectronic Genesys-5 (Milton Roy Com-

pany, New York, USA). Samples were also stored at 47Cin

a refrigerator, to monitor a tendency for retrogradation,

and the transmittance of samples was determined during

cold storage for up to seven days.

3 Results and Discussion

3.1 Carbonyl and carboxyl contents

The carbonyl and carboxyl contents of oxidized cassava

starches as a function of reaction pH and time are shown

in Figs. 1 and 2. All oxidized samples contained higher

amounts of carboxyl than carbonyl groups which is in

accordance with the earlier works reporting that hypo-

chlorite oxidation of starch under alkaline conditions

favored the formation of carboxyl group [12]. The alkali-

nity level during modification process had a significant

influence on the type and amount of functional groups

formed in the oxidized starch. Within the pH range stud-

ied, the amount of carbonyl groups was highest at pH 8

and decreased as the reaction pH increased, which is in

agreement with previous reports [6, 9]. Irrespective of

reaction pH, the rate of carbonyl group formation was

fast. After 30 min of reaction time, no change in carbonyl

content was observed (Fig. 1).

As shown in Fig. 2, the highest formation of carboxyl

groups was observed when the oxidation was conducted

under mildly alkaline conditions (pH 8 and 9). Under these

conditions, the rate of carboxyl group formation was also

fast; carboxyl content remained constant after only 30

min of reaction time. As the reaction pH increased to 10

and 11, the amount of carboxyl groups and its formation

rate decreased. The present result differs from earlier

studies [6, 9] which reported that the formation of car-

boxyl group was more favorable at higher reaction pH.

This discrepancy might be due to different conditions

employed in the reactions. In earlier studies, more drastic

conditions with much longer reaction times were used.

The milder conditions and the range of reaction times

used in the current study were more relevant to the

industrial practice; thus, the results obtained could be

pertinent to the industrial applications.

3.2 Viscosity and viscosity stability of starch

paste

The apparent viscosity of oxidized starch was measured

in a 15% suspension and at 507C. Under these condi-

tions, the paste from native cassava starch was too vis-

© 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.starch-journal.com

Starch/Stärke 61 (2009) 92–100 Physicochemical Properties of Oxidized Cassava Starch 95

Fig. 1. Carbonyl content of

native and oxidized cassava

starches prepared under dif-

ferent reaction pH and

times. Native (

), pH 8 ( ),

pH 9 (

), pH 10 ( ), and pH

11 (

).

Fig. 2. Carboxyl content of

native and oxidized cassava

starches prepared under dif-

ferent reaction pH and

times. Native (

), pH 8 ( ),

pH 9 (

), pH 10 ( ), and pH

11 (

).

cous to measure; hence its viscosity was not deter-

mined. The effects of reaction pH and time on the

initial viscosity and viscosity stability of the starch

paste (as demonstrated by the changes in the paste

viscosity after 8 h storage) are presented in Tab. 1. As

noted from the fresh pastes, the viscosity of oxidized

starches progressively decreased with increasing

reaction time. This decrease was presumably caused

by partial cleavage of the glucosidic linkages upon

oxidation, resulting in a decrease in molecular weight

of starch molecules [4, 15]. The rate and extent of

viscosity reduction varied depending on the alkalinity

levels during modification process. Modification under

the highest alkalinity level (i.e. pH 11) yielded oxidized

starch with the lowest paste viscosity. In addition to

oxidative cleavage, alkaline degradation could con-

tribute to the higher degree of viscosity reduction

observed for oxidized starch modified under strongly

alkaline conditions [16].

Improved stability of starch dispersions is one of the key

characteristics desired from oxidized starch. It has been

suggested that carboxyl groups introduced to starch

molecules would hinder the chain re-association or retro-

gradation; hence improving the viscosity stability of the

starch paste [12]. In this study, the viscosity of starch

paste after being maintained at 507C for 8 h was deter-

mined and compared with the viscosity of the fresh paste

(Tab. 1). The data indicated that reaction pH and time

significantly influenced the stability of the starch paste.

Two different characteristics were observed for oxidized

starches modified under various reaction pHs. Starch

© 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.starch-journal.com

96 K. Sangseethong et al. Starch/Stärke 61 (2009) 92–100

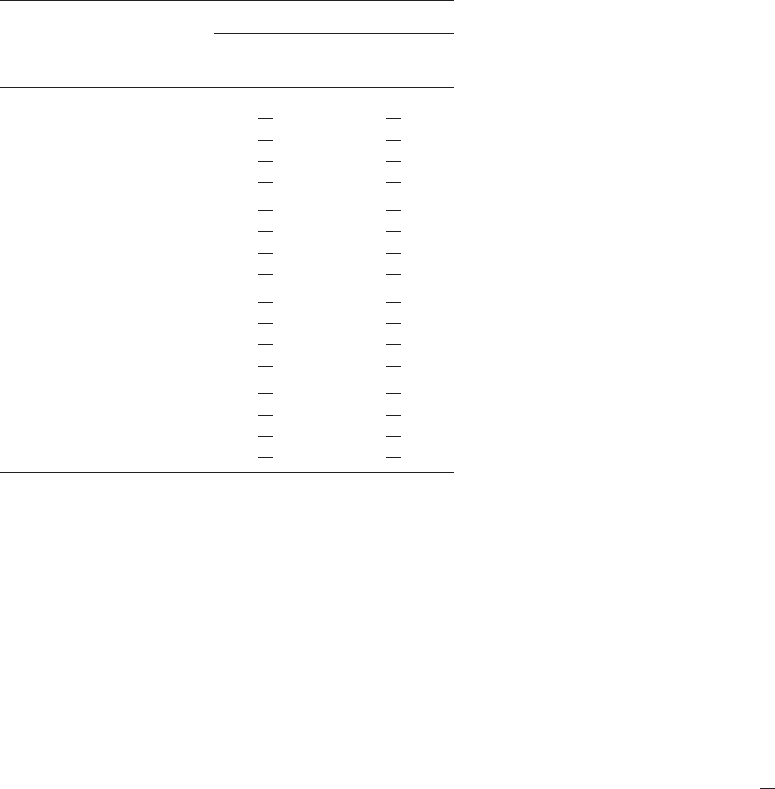

Tab. 1. Viscosity (mPa s) of fresh and stored (8 h at 507C)

oxidized cassava starch pastes (15% solid)

measured at a shear rate of 22 s

-1

and a temper-

ature of 507C.

Reaction

pH

Reaction

time [min]

Storage time [h]

0

(fresh paste)

8

(stored paste)

8 30 3570

1 124 302 1 7.2

60 1430

1 184 109 1 11

120 64

1 5.9 49 1 2.0

300 31

1 1.7 29 1 1.1

9 30 3965 1 134 2870 1 184

60 2460

1 353 1660 1 138

120 1370

1 175 445 1 33

300 70

1 6.8 65 1 4.7

10 30 3250

1 200 4030 1 330

60 122

1 7.5 313 1 29

120 46

1 1.7 57 1 2.1

300 30

1 2.3 34 1 1.8

11 30 401

1 29 4360 1 328

60 44

1 2.5 121 1 14

120 19

1 1.3 23 1 0.7

300 15

1 0.1 17 1 1.3

modified under the milder alkaline conditions (pH 8 and 9)

exhibited a decrease in paste viscosity during storage. In

contrast, starch modified at higher alkalinity (pH 10 and

11) showed an increase in viscosity after storage. Irre-

spective of reaction pH, the changes in paste viscosity

were prominent for starch modified with shorter reaction

time. The stability of the viscosity of the starch paste was

much improved when the oxidation was performed at

longer reaction time (300 min).

It might be expected that the reduction in the viscosity of

the stored paste observed for oxidized starch modified at

pH 8 and 9 was attributed to depolymerization of the

starch molecules. The fact that this behavior was not

observed for the samples modified at higher pH values

implied that hypochlorite oxidation under different alkali-

nity levels would yield oxidized products with different

molecular structures. Modification at the milder alkalinity

levels might lead to oxidized starch with more labile

structures that are sensitive to degradation or hydrolysis,

causing a viscosity decrease of starch paste during stor-

age. Prey and Siklossy [17] observed a similar phenom-

enon. In their study, although the oxidized starch was kept

in a dry powder form, after one year a substantial reduc-

tion in starch viscosity was noted. They related this

observation to the presence of aldehyde/carbonyl

groups. Starch with higher aldehyde/carbonyl content

exhibited a larger degree of viscosity reduction. In our

current study, similar results were observed. Starch

modified under more mildly alkaline conditions, which

contained a higher fraction of carbonyl groups (Fig. 1),

exhibited a high degree of viscosity reduction.

For starch modified at the higher alkalinity levels (pH 10

and 11), the paste viscosity significantly increased after

storage. The increase in viscosity of the stored paste

observed in this group of samples could be due to the

intermolecular re-association or retrogradation of the

starch molecules. The extent was more pronounced for

starch oxidized with a shorter reaction time, indicating

that starch with low degree of oxidation had a higher ten-

dency for retrogradation. As the degree of oxidation

increased (i.e. samples with longer reaction time), the

paste viscosity seemed to be more stable. The marked

decrease in molecular size and the substantial increase in

carboxyl content were likely responsible for the lower

tendency for molecular re-association in these samples.

3.3 Gelatinization properties

The gelatinization properties of native and oxidized cas-

sava starches measured by DSC are summarized in Tab.

2. In general, the onset of gelatinization temperature (T

o

)

and the gelatinization enthalpy (DH

g

) of the oxidized star-

ches were lower than those of native starch, and the

extent of changes varied with modification conditions.

Many studies have reported the influence of oxidation on

the gelatinization properties of starch but the results are

somewhat inconclusive and seem to depend on starch

origin as well as the modification conditions. Forssell et al.

[3] observed an increase in T

o

of oxidized barley starch,

while the T

o

of oxidized potato starch remained unchan-

ged. Wang and Wang [11] reported an increase in T

o

of

oxidized waxy and common corn starches, when a low

concentration of hypochlorite (

, 1.25% active chlorine)

was used in the modification process. However, when the

oxidant concentration was increased (up to 5% active

chlorine), a decrease in T

o

of oxidized starches was noted

[5]. In our current study, a decrease in T

o

of oxidized cas-

sava starches was observed, which could be attributed to

the introduction of carboxyl groups into the starch mole-

cules. It is expected that the carboxyl group carrying a

negative charge could readily adsorb water and facilitate

hydration, thus causing an increase in the swelling of

starch granules and a decrease in the gelatinization tem-

perature.

The extent of decrease in T

o

of the oxidized starch (as

shown in Tab. 2) was strongly related to the carboxyl

group content in the starch sample (Fig. 2). Oxidized

starch produced under the milder alkaline conditions (pH

8 and 9), which contained a higher amount of carboxyl

© 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.starch-journal.com

Starch/Stärke 61 (2009) 92–100 Physicochemical Properties of Oxidized Cassava Starch 97

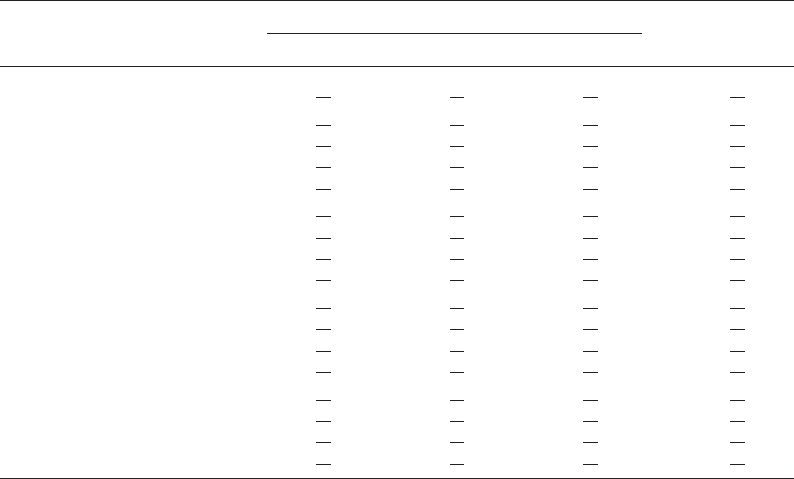

Tab. 2. Gelatinization properties of native and oxidized cassava starches.

Reaction pH Reaction

time [min]

Transition temperature [7C] Gelatinization

enthalpy [J/g]

T

o

T

p

T

c

Native - 64.26 1 0.02 71.70 1 0.00 81.00 1 0.02 17.40 1 0.13

8 30 60.05

1 0.07 67.40 1 0.00 90.74 1 0.03 15.33 1 0.24

60 60.52

1 0.04 68.15 1 0.49 88.24 1 1.05 15.37 1 0.34

120 61.34

1 0.57 68.95 1 0.92 89.37 1 0.21 14.28 1 1.15

300 60.68

1 0.19 68.45 1 0.21 90.48 1 0.47 15.14 1 0.04

9 30 59.84

1 0.73 67.70 1 0.99 81.42 1 0.32 15.74 1 0.24

60 59.43

1 0.43 66.90 1 0.85 87.53 1 0.40 15.55 1 0.54

120 58.60

1 0.08 65.70 1 0.14 88.47 1 0.33 15.05 1 0.05

300 59.63

1 0.18 67.20 1 0.57 89.12 1 0.01 14.92 1 0.02

10 30 62.94

1 0.16 70.85 1 0.21 85.36 1 0.96 16.56 1 0.22

60 61.94

1 0.31 68.85 1 0.35 88.28 1 0.37 15.94 1 0.43

120 61.73

1 0.37 69.20 1 0.42 88.83 1 0.25 15.63 1 0.17

300 61.59

1 0.18 68.90 1 0.00 89.92 1 0.41 14.14 1 0.03

11 30 64.46

1 0.16 72.25 1 0.07 86.64 1 1.77 16.14 1 0.33

60 64.08

1 0.19 71.65 1 0.64 89.44 1 0.18 15.49 1 0.28

120 63.54

1 0.08 71.15 1 0.35 91.50 1 0.21 14.20 1 0.05

300 63.08

1 0.22 70.70 1 0.71 91.93 1 0.64 14.40 1 0.50

groups exhibited a greater reduction in T

o

. On the other

hand, starch modified at higher pH containing a lower

amount of carboxyl groups showed a smaller decrease in

T

o

. Although carboxyl content markedly correlated to the

changes in T

o

of oxidized starch, this factor alone cannot

completely explain the differences in T

o

between some of

the oxidized samples. For instance, starch oxidized at pH

11 with reaction times longer than 60 min had a higher

carboxyl content but exhibited a smaller reduction in T

o

when compared to oxidized starch obtained at pH 10 with

a reaction time of 30 min. This suggests that other factors

such as the distribution or location of functional groups

and the degradation pattern of starch molecules might

also play important roles in determining the gelatinization

properties of oxidized starch [5, 18].

The gelatinization enthalpies (DH

g

) of oxidized starches

were lower than that of native starch. The decrease of D H

g

indicated that oxidation caused a weakening of the starch

granules, probably from the partial degradation of starch

molecules in the crystalline lamellae. Consequently, less

energy was needed to gelatinize starch.

3.4 Retrogradation properties

The retrogradation properties of native and oxidized star-

ches after storage at 47C for seven days are summarized

in Tab. 3. It has been suggested that the starch fraction

responsible for retrogradation, as measured by DSC, is

amylopectin [19]. Therefore, the retrogradation enthalpies

(DH

r

) observed during the melting of retrograded samples

represent the relative degrees of amylopectin retro-

gradation. Data in Tab. 3 shows that oxidized starches

tended to have higher DH

r

than the native starch, indicat-

ing that oxidized starches had a higher tendency for

retrogradation. The influences of hypochlorite oxidation

on retrogradation properties of starch reported previously

are somewhat different. Lawal et al. [20] and Sandhu et al.

[21] observed a decrease in DH

r

of oxidized starches

while Kuakpetoon and Wang [5] found a slight increase.

In general, the introduction of negatively charged carboxyl

groups into the starch molecules would be expected to

hinder the chain re-association and minimize retro-

gradation. However, the results observed in our current

study indicated that the introduced carboxyl groups could

not prevent amylopectin retrogradation. It is possible that

most carboxyl groups were formed close to the branching

points of the amylopectin chains, as also suggested by

Kuakpetoon and Wang [5], or on the amylose molecules.

In such positions, they were not very effective in prevent-

ing the recrystallization of the amylopectin chains. The

increased DH

r

observed in the oxidized starches might be

explained by another mechanism of oxidation on starch

molecules. It has been known that, in addition to forma-

tion of functional groups, oxidation also causes depolym-

erization of the starch molecules. An increase in the DH

r

of

oxidized starch might be due to the degradation of long-

chain amylopectin or even amylose molecules, produc-

ing dextrins with an appropriate length for retro-

© 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.starch-journal.com

98 K. Sangseethong et al. Starch/Stärke 61 (2009) 92–100

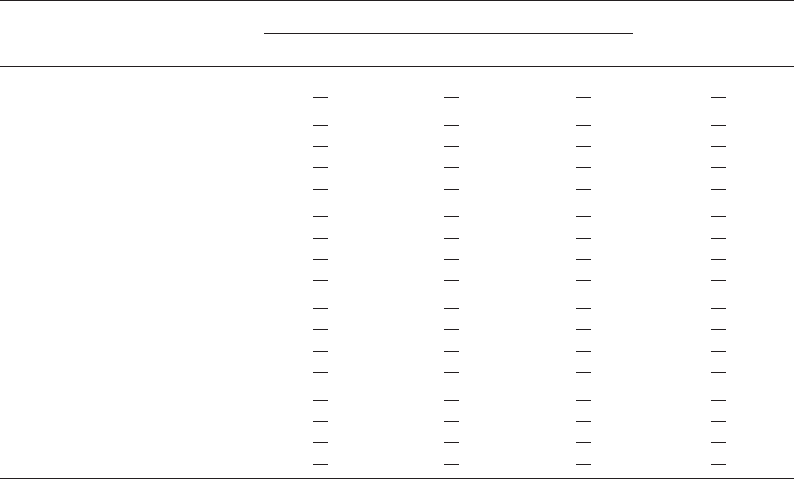

Tab. 3. Retrogradation properties of native and oxidized cassava starches.

Reaction pH Reaction

time [min]

Transition temperature [7C] Retrogradation

enthalpy [J/g]

T

o

T

p

T

c

Native - 42.80 1 0.25 53.85 1 0.35 61.98 1 0.12 6.13 1 0.21

8 30 42.35

1 0.11 54.65 1 0.07 65.09 1 0.16 7.08 1 0.02

60 42.67

1 0.13 54.60 1 0.14 64.82 1 0.03 7.06 1 0.12

120 43.09

1 0.20 54.60 1 0.28 64.89 1 0.35 7.79 1 0.24

300 43.37

1 0.13 54.85 1 0.07 64.87 1 0.29 8.47 1 0.20

9 30 40.10

1 0.25 51.90 1 0.14 63.67 1 0.05 6.61 1 0.31

60 40.66

1 0.07 52.30 1 0.00 63.76 1 0.01 6.33 1 0.05

120 41.25

1 0.40 52.85 1 0.21 63.85 1 0.01 6.27 1 0.03

300 41.46

1 0.10 52.90 1 0.00 63.70 1 0.03 6.18 1 0.15

10 30 42.18

1 0.00 53.00 1 0.00 62.86 1 0.07 5.95 1 0.02

60 42.69

1 0.21 52.75 1 0.07 62.73 1 0.02 6.29 1 0.16

120 42.58

1 0.23 53.05 1 0.21 62.64 1 0.13 6.81 1 0.23

300 42.93

1 2.60 53.85 1 1.73 63.94 1 1.32 6.68 1 1.06

11 30 39.80

10.22 51.50 1 0.28 62.57 1 0.21 6.44 1 0.03

60 40.47

1 0.22 52.15 1 0.21 62.93 1 0.21 6.67 1 0.09

120 41.35

1 0.05 52.80 1 0.14 63.50 1 0.47 7.00 1 0.20

300 42.08

1 0.06 53.15 1 0.07 63.82 1 0.23 7.23 1 0.07

gradation [5]. Results in Tab. 3 suggested that starch oxi-

dized under various reaction conditions might have dif-

ferent degradation patterns resulting in oxidized products

with different degrees of amylopectin retrogradation.

3.5 Light transmittance of starch paste

The tendency for retrogradation of native and oxidized

starches was also determined by following the changes in

light transmittance of starch pastes during storage at 47C

for seven days (Fig. 3). The initial transmittance of the

paste from native starch was at an intermediate level

(about 53%). As suggested by Craig et al. [22], the mod-

erate clarity and whiteness observed in the paste of native

cassava starch was attributed to the association of starch

molecules to form junction zones, which occurred shortly

after cooling the gelatinized paste. On the other hand,

pastes prepared from oxidized starches showed much

higher initial transmittance than native starch, indicating

that oxidized starch had a lower tendency for molecular

re-association. The presence of hydrophilic functional

groups, especially carboxyl groups, in oxidized starches

might be responsible for the higher transmittance, as

supported by the positive correlation between the car-

boxyl content and the initial light transmittance of oxi-

dized starches (Figs. 2 and 3). It has been suggested that

the early development of starch retrogradation is domi-

nated by the association of amylose [23]. Therefore, it is

possible that during starch oxidation most of or at least

part of the carboxyl groups were formed on amylose

molecules; thus, effectively retarding their re-association.

During cold storage, the transmittance of native starch

paste decreased rapidly (reaching 6% after one day stor-

age), indicating a progressive increase in the extent of

starch retrogradation. On the other hand, much less

changes in transmittance were observed for the oxidized

starch pastes, and the extent of changes was strongly

related to the amount of carboxyl group present in the

starch. Oxidized starches produced under the milder

alkaline conditions (pH 8 and 9), which had higher carboxyl

contents exhibited constant light transmittance through-

out the storage period whereas starches modified at the

higher alkaline levels (pH 10 and 11) containing lower car-

boxyl contents showed larger decrease in light transmit-

tance of starch pastes. It appeared that the more carboxyl

groups the starch contained, the smaller changes were

observed in the light transmittance. Unlike DSC results

which demonstrated that hypochlorite oxidation could not

prevent retrogradation of amylopectin, the results

observed from the changes in light transmittance of starch

paste indicated that the carboxyl groups introduced to

oxidized starch could effectively prevent starch retro-

gradation. The discrepancy of results between DSC and

light transmittance is possibly due to the differences in the

nature of these two analytical techniques. To analyze ret-

rogradation by DSC, a high starch concentration is

required (30% in this case). The gelatinization of starch in a

calorimeter pan produces swollen but nondisrupted

© 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.starch-journal.com

Starch/Stärke 61 (2009) 92–100 Physicochemical Properties of Oxidized Cassava Starch 99

Fig. 3. Light transmittance of starch pastes from native and oxidized cassava starches prepared with different reaction pH

and times during storage at 47C for 7 days. Native starch (

), oxidized starch prepared with reaction time of 30 min ( ), 60

min (

), 120 min ( ) and 300 min ( ).

granules. The pan is then subjected to retrogradation

conditions, and the contents are analyzed by DSC [24]. In

such conditions, the localized carboxyl groups formed in

starch molecules, especially those on amylose and on the

branching points of amylopectin, might not be very

effective in preventing the re-crystallization of amylo-

pectin chains. In contrast, to analyze retrogradation ten-

dency by light transmittance, a low-concentrated starch

slurry is heated in a boiling water bath with continuous

stirring. This condition facilitates granule swelling and

promotes starch molecular dispersion. The starch mole-

cules carrying carboxyl groups are mingled with mole-

cules that do not contain functional groups. In this way,

the carboxyl groups could sterically hinder the aggrega-

tion of starch molecules, resulting in a lower degree of

retrogradation.

4 Conclusion

Hypochlorite oxidation under alkaline conditions tended

to favor the formation of carboxyl over carbonyl groups.

The alkalinity levels during the modification process play

an important role in determining the physicochemical

properties of the oxidized starch. Oxidation conducted

under milder alkaline conditions produced higher

amounts of functional groups; however, the extent of

viscosity reduction was much greater when oxidation

was conducted under condition with higher alkalinity.

The gelatinization temperature and the enthalpy of

gelatinization of oxidized starches were lower than

those of native starch. The presence of carboxyl groups

appeared to be responsible for the decrease in the

gelatinization temperature of oxidized starches. DSC

study revealed that hypochlorite oxidation could not

prevent the re-association of amylopectin chains. On

the other hand, the results from light transmittance of

starch paste during cold storage suggested that car-

boxyl groups introduced to oxidized starch could effec-

tively retard starch retrogradation.

Acknowledgement

This work was supported by the National Center for

Genetic Engineering and Biotechnology (BIOTEC), the

National Science and Technology Development Agency,

Ministry of Science and Technology, Thailand.

© 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.starch-journal.com

100 K. Sangseethong et al. Starch/Stärke 61 (2009) 92–100

References

[1] R. L. Whistler, E. G. Linke, S. Kazeniac: Action of alkaline

hypochlorite on corn starch amylose and methyl 4-O-

methyl-D-glucopyranosides. J. Am. Chem. Soc. 1956, 78,

4704–4709.

[2] R. L. Whistler, R. Schweiger: Oxidation of amylopectin with

hypochlorite at different hydrogen ion concentrations. J.

Am. Chem. Soc. 1957, 79, 6460–6464.

[3] P. Forssell, A. Hamunen, K. Autio, T. Suortti, K. Poutanen:

Hypochlorite oxidation of barley and potato starch. Starch/

Stärke 1995, 47, 371–377.

[4] D. Kuakpetoon, Y. J. Wang: Characterization of different

starches oxidized by hypochlorite. Starch/Stärke 2001, 53,

211–218.

[5] D. Kuakpetoon, Y. J. Wang: Structural characteristics and

physicochemical properties of oxidized corn starches vary-

ing in amylose content. Carbohydr. Res. 2006, 341, 1896–

1915.

[6] J. Schmorak, M. Lewin: The chemical and physicochemical

properties of wheat starch mildly oxidized with alkaline

sodium hypochlorite. J. Polym. Sci.: Part A 1963, 1, 2601–

2620.

[7] J. Schmorak, D. Mejzler, M. Lewin: A kinetic study of the

mild oxidation of wheat starch by sodium hypochlorite in the

alkaline pH range. J. Polym. Sci. 1961, 49, 203–216.

[8] K. F. Patel, H. U. Mehta, H. C. Srivastava: Kinetic and

mechanism of oxidation of starch with sodium hypochlorite.

J. Appl. Polym. Sci. 1974, 18, 389–399.

[9] C. H. Hullinger, R. L. Whistler: Oxidation of amylose with

hypochlorite and hypochlorous acid. Cereal Chem. 1951,

28, 153–157.

[10] K. Sangseethong, K. Sriroth: Effect of hypochlorite levels on

the modification of cassava starch. Zywnosc Technologia

Jakosc 2002, 9, 191–197.

[11] Y. J. Wang, L. Wang: Physicochemical properties of com-

mon and waxy corn starches oxidized by different levels of

sodium hypochlorite. Carbohydr. Polym. 2003, 52, 207–217.

[12] O. B. Wurzburg: Converted starches, in Modified Starches:

Properties and Uses (Ed. O. B. Wurzburg) CRC Press, Boca

Raton, Florida, 1986.

[13] Food and Agriculture Organization (FAO): FAO Food and

Nutrition Paper 52 Addendum 9. Food and Agriculture

Organization of the United Nations, 2001.

[14] M. R. Jacobson, M. Obanni, J. N. BeMiller: Retrogradation

of starches from different botanical sources. Cereal Chem.

1997, 74, 511–518.

[15] M. W. Rutenberg, D. Solarek: Starch derivatives: production

and uses, in Starch: Chemistry and Technology,2

nd

ed. (Eds.

R. L. Whistler, J. N. BeMiller, E. F. Paschall) Academic Press,

New York, 1984.

[16] J. N. BeMiller: Alkaline degradation of starch, in Starch:

Chemistry and Technology, vol. 1 (Eds. R. L. Whistler, E. F.

Paschall) Academic Press, New York, 1965.

[17] V. V. Prey, S. Siklossy: Die Rolle der Aldehydgruppen in

hypochloritoxydierten Stärken. Stärke 1971, 23, 235–238.

[18] D. Kuakpetoon, Y. J. Wang: Locations of hypochlorite oxi-

dation in corn starches varying in amylose content. Carbo-

hydr. Res. 2008, 343, 90–100.

[19] A. A. Karim, M. H. Norziah, C. C. Seow: Methods for the

study of starch retrogradation. Food Chem. 2000, 71, 9–36.

[20] O. S. Lawal, K. O. Adebowale, B. M. Ogunsanwo, L. L.

Barba, N. S. Ilo: Oxidized and acid thinned starch deriva-

tives of hybrid maize: functional characteristics, wide-angle

X-ray diffractometry and thermal properties. Int. J. Biol.

Macromol. 2005, 35, 71–79.

[21] K. S. Sandhu, M. Kaur, N. Singh, S. T. Lim: A comparison of

native and oxidized normal and waxy corn starches: physi-

cochemical, thermal, morphological and pasting properties.

Lebensm. Wiss. Technol. 2008, 41, 1000–1010.

[22] S. A. S. Craig, C. C. Maningat, P. A. Seib, R. C. Hoseney:

Starch paste clarity. Cereal Chem. 1989, 66, 173–182.

[23] M. J. Miles, V. J. Morris, P. D. Orford, S. G. Ring: The roles of

amylose and amylopectin in the gelation and retrogradation

of starch. Carbohydr. Res. 1985, 135, 271–278.

[24] M. R. Jacobson, J. N. BeMiller: Method for determining the

rate and extent of accelerated starch retrogradation. Cereal

Chem. 1998, 75, 22–29.

(Received: July 10, 2008)

(Revised: August 8, 2008)

(Accepted: September 10, 2008)

© 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.starch-journal.com