CONTEXT02B

INCREASE PRODUCTION • REDUCE MAINTENANCE • REDUCE DOWNTIME • REDUCE SCRAP

CONTINUOUS EXTRUSION

PROCESS IMPROVEMENTS

NEEDLE CYLINDERS

KNOCKOUT CYLINDERS

phdinc.com (800) 624-8511

www.phdinc.com

•

(800) 624-8511

2

CONTEXT02B

We understand

Focused on the specific needs of the plastic packaging industry,

PHD has worked with a wide range of continuous extrusion

OEMs and user accounts to produce a variety of improved

solutions for the industry.

Our components are the actuators of choice. Designed for long

life, PHD products keep your blow molding lines running while

increasing productivity and reducing downtime and scrap.

We also offer the added benefit of our rebuild program which

refurbishes your existing PHD components, enabling even

longer service life and savings.

© Copyright 2019, by PHD, Inc. All Rights Reserved. Printed in the U.S.A.

your unique

requirements

We offer a wide variety of direct replacement components.

Our drop-in components save you money by reducing costly

production downtime and maintenance costs.

Many of our components provide up to twice the life of the

original unit. This means longer run time for higher production

and higher profits.

With longer life,

reduced maintenance,

and reduced downtime

Easy Drop-in

Excellent delivery saves you money by getting you back to

business faster.

FASTER

delivery than

competitor

Superior Delivery

PHD offers a variety of components already designed

to fit unique requirements. If your application

requires a modified component from outside our

large database of designs, our team is ready to help.

We welcome special requests, regardless of quantity

or frequency of order. See page 14.

Special

Requirements

Unique Solutions

Our products can be rebuilt and put back in service

for continued savings. Plus you will receive a “like

new” warranty. See page 15 for more information.

Return

to Service

Rebuild Program

To request more literature, visit

www.phdinc.com/resources/inforequest/

www.phdinc.com

•

(800) 624-8511

3

CONTEXT02B

Any marks or names referenced herein are either registered trademarks or trademarks of their respective owners. No

association with or endorsement of any company, organization, or product is intended or should be inferred.

Replacement Reference Chart & Contents

NEEDLE CYLINDERS PAGE

Series BCT 4

Series BCN 11

Other Unique Solutions 14

KNOCKOUT CYLINDERS PAGE

Series CV Style 14

Series AV Style 14

Special Rod Style 14

ML304949

ML310701

ML306733

www.phdinc.com/bct

•

(800) 624-8511

4

CONTEXT02B

BCT

Needle Cylinder

Major Benefits

• Direct OEM solution used in continuous extrusion

wheels are available in three bore sizes and provide

superior blow pressure and exhaust

• Non-rotating shaft to keep needle tip in

correct orientation

• BCT2 (High Flow) version increases run time

between cleaning of “plate out” material

• Standard NPT ports for extend, retract and blow

• Internal shock pads standard on extend and retract

• Lubricated internally at factory for life of cylinder

using lubricant per FDA Regulation 21CFR 178.3570

• Option -H96 for mirrored porting and non-

rotating shaft, designed to help eliminate

machine interferences

• Cylinders are easily field repairable to maximize

your investment

Self-lubricating nitrile piston

seal provides long life

Non-rotating

hardened steel shaft

Rugged mechanically joined

piston and rod assembly

Self-lubricating nitrile rod

seals provide long life

Built-in shock pads are standard,

absorbing impact energy and

eliminating metal to metal contact

Hard chrome-plated steel

piston rods provide maximum

wear resistance for long life

Aluminum bushings

with PTFE filled hardcoat

provide maximum wear

resistance for long life

Standard NPT porting

for extend and retract

Clear anodized extruded body

NPT manifold

porting

Composite bushing

BCT1

(Manifold)

NPT end porting for

higher flow requirements

and increased time

interval between cleaning

BCT2

(High Flow)

BCT1 (Manifold)

BCT2 (High Flow)

BCT Needle

Cylinder

Continuous

Extrusion Wheel

www.phdinc.com/bct

•

(800) 624-8511

5

CONTEXT02B

ORDERING DATA: SERIES BCT NEEDLE CYLINDER

x

TO ORDER, SPECIFY:

Product Line, Series, Product Type, Build Type,

Design No., Bore Size, Stroke, Cylinder Options

NOTES:

1) Standard Needle Cylinder ordering number is as follows:

BCT1-1-50 x 35

2) -W1 option needs to be specified for flange to be attached to unit

-

1C 32T

H96

OPTIONS

W1

-

Attached Flange - 2.0 x 2.0 Square Mount Pattern

(for Ø 32 and Ø 50 only)

H96

-

Mirror Port and Non-Rotating Shaft

25

PRODUCT LINE

B - Blow Molding

B

SERIES

C - Cylinder

1

DESIGN NO.

1 - Imperial

BORE SIZE (mm)

32

40

50

--

BUILD TYPE

1 - Standard-Manifold

2 - High Flow

STROKE

Contact PHD for other strokes

STANDARD STROKE (mm)

25

20, 40

35

BORE

32

40

50

PRODUCT TYPE

T - Compact

Non-Rotating

SPECIFICATIONS SERIES BCT

OPERATING PRESSURE 20 psi min to 150 psi max at zero load [1.4 bar min to 10 bar max] air

STROKE TOLERANCE ±0.031 in [0.8 mm]

TEMPERATURE LIMITS -20 to +180°F [-28 to +82°C]

VELOCITY 20 in/sec [0.5 m/sec] typical min, zero load at 100 psi [7 bar]

LIFE EXPECTANCY 30 million linear inches [762000 linear meters] min

LUBRICATION Lubrication per FDA Regulation 21CFR 178.3570

MAINTENANCE Field repairable

CYLINDER FORCE AND WEIGHT

BORE

ROD

DIRECTION

OUTLET ROD DIAMETER EFFECTIVE AREA BCT1 BASE WEIGHT BCT2 BASE WEIGHT ADDER PER 5 mm OF STROKE

mm in in mm in² mm² lb kg lb kg lb kg

32 1.260

Extend 0.750 19.1 0.805 519

0.62 0.23 0.59 0.22 0.07 0.03

Retract 0.625 15.9 0.904 583

40 1.575

Extend 0.750 19.1 1.506 972

0.69 0.26 0.64 0.24 0.13 0.05

Retract 0.625 15.9 1.641 1059

50 1.969

Extend 0.750 19.1 2.603 1679

1.03 0.38 0.97 0.36 0.10 0.04

Retract 0.750 19.1 2.603 1679

CYLINDER FORCE CALCULATIONS

Imperial Metric

F = P x A F = 0.1 x P x A

F = Cylinder Force lbs N

P = Operating Pressure psi bar

A = Effective Area

(Extend or Retract)

in

2

mm

2

ENGINEERING DATA: SERIES BCT NEEDLE CYLINDER

www.phdinc.com/bct

•

(800) 624-8511

6

CONTEXT02B

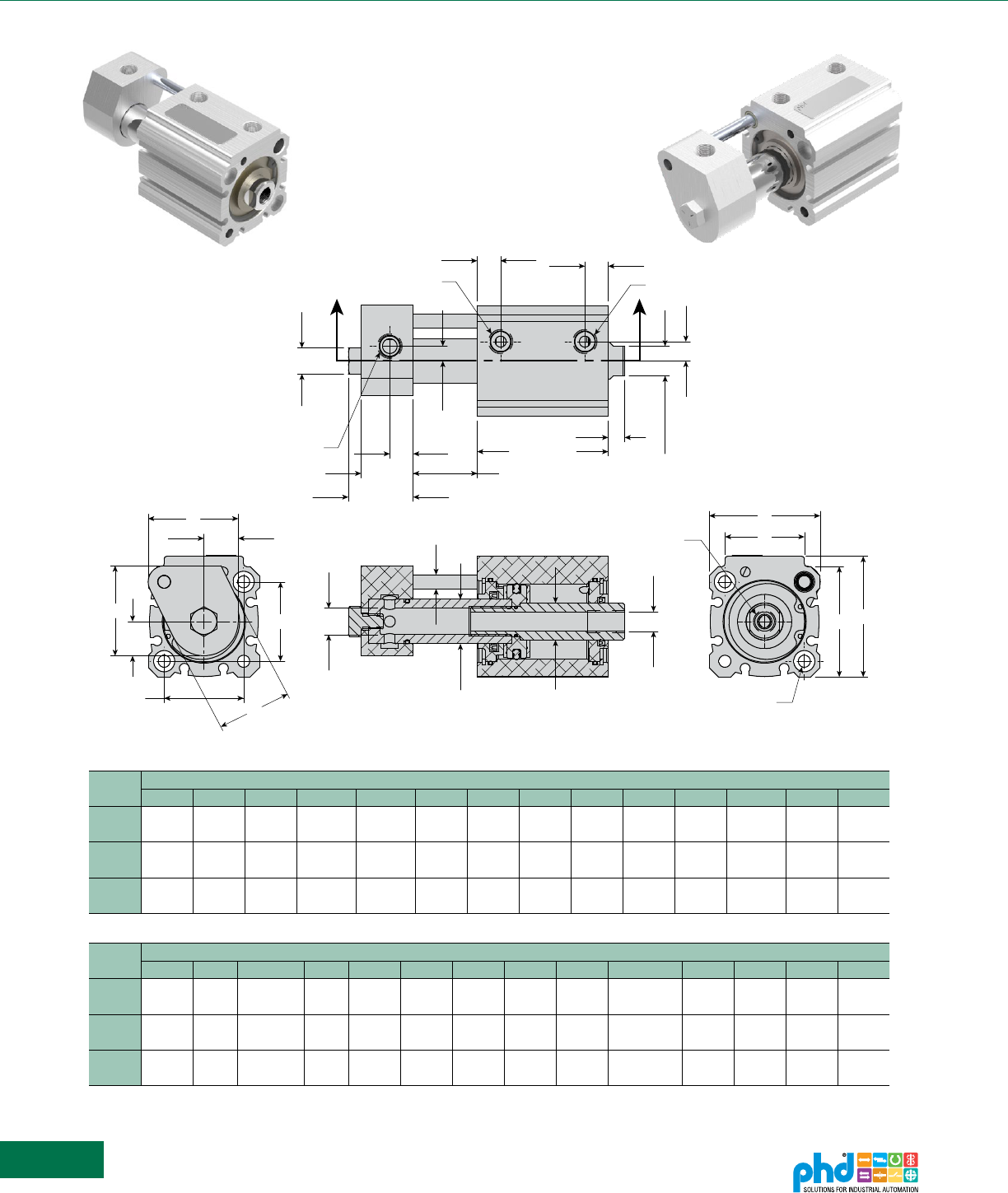

DIMENSIONS: SERIES BCT1 NEEDLE CYLINDER

BORE

DIMENSIONS

A B C D1 D2 E F G H J K K1 L M

32

1.519 0.579 1.250 0.750 0.625 1.870 1.339 0.437 0.330 1.224 0.394 0.250 0.394 0.394

[38.6] [14.7] [31.8] [19.1] [15.9] [47.5] [34.0] [11.1] [8.4] [31.1] [10.0] [6.4] [10.0] [10.0]

40

1.699 0.600 1.250 0.750 0.625 2.205 1.574 0.437 0.330 1.148 0.394 0.349 0.394 0.394

[43.2] [15.2] [31.8] [19.1] [15.9] [56.0] [40.0] [11.1] [8.4] [29.2] [10.0] [8.9] [10.0] [10.0]

50

1.876 0.626 1.250 0.750 0.750 2.598 1.968 0.437 0.330 1.292 0.394 0.438 0.470 0.470

[47.7] [15.9] [31.8] [19.1] [19.1] [66.0] [50.0] [11.1] [8.4] [32.8] [10.0] [11.1] [11.9] [11.9]

BORE

DIMENSIONS

N P R THREAD S T U V W Y Z THREAD AA BB CC DD

32 1/8 NPT

0.326

1/4 NPT 10-24

0.394 0.276 0.500 2.037 1.340

3/8-24 x

0.625

0.236 0.875 0.098 1.094

[8.3] [10.0] [7.0] [12.7] [51.7] [34.0] [6.0] [22.2] [2.5] [27.8]

40 1/8 NPT

0.365

1/4 NPT 10-24

0.394 0.276 0.500 2.363 1.420

3/8-24 x

0.625

0.236 0.875 0.175 1.094

[9.3] [10.0] [7.0] [12.7] [60.0] [36.1] [6.0] [22.2] [4.4] [27.8]

50 1/4 NPT

0.476

1/4 NPT 1/4-20

0.394 0.315 0.625 2.795 1.600

1/2-20 x

0.750

0.236 0.875 0.108 1.094

[12.1] [10.0] [8.0] [15.9] [71.0] [40.6] [6.0] [22.2] [2.7] [27.8]

DIMENSIONS IN [ ] ARE mm

A

A

B

B

F

F

C

R PORT (BLOW)

N PORT (RETRACT)

N PORT (EXTEND)

M

L

J + STROKE

CC + STROKE

K

U

BB

T WRENCH FLAT

V WRENCH FLAT

0.189 [4.8] LONG

P

K1

DD

Z THREAD

Y

E

W

E

2X THRU & C BORE FOR S

SOCKET HEAD CAP SCREW

(BOTH ENDS)

Ø AA

Ø D1

Ø D2

Ø HØ G

All dimensions are reference only unless specifically toleranced.

www.phdinc.com/bct

•

(800) 624-8511

7

CONTEXT02B

DIMENSIONS: SERIES BCT2 NEEDLE CYLINDER

BORE

DIMENSIONS

A B C D1 D2 E F G H J K L M

32

1.856 0.751 1.250 0.750 0.625 1.870 1.339 0.437 0.330 1.224 0.375 0.394 0.394

[47.1] [19.1] [31.8] [19.1] [15.9] [47.5] [34.0] [11.1] [8.4] [31.1] [9.5] [10.0] [10.0]

40

1.856 0.751 1.250 0.750 0.625 2.205 1.574 0.437 0.330 1.148 0.375 0.394 0.394

[47.1] [19.1] [31.8] [19.1] [15.9] [56.0] [40.0] [11.1] [8.4] [29.2] [9.5] [10.0] [10.0]

50

2.036 0.666 1.250 0.750 0.750 2.598 1.968 0.437 0.330 1.292 0.375 0.470 0.470

[51.7] [16.9] [31.8] [19.1] [19.1] [66.0] [50.0] [11.1] [8.4] [32.8] [9.5] [11.9] [11.9]

BORE

DIMENSIONS

N P R THREAD S T U V W Y Z THREAD AA BB CC

32 1/8 NPT

0.326

1/4 NPT 10-24

0.632 0.276 0.500 2.037 1.340

3/8-24 x 0.625

0.236 0.702 0.098

[8.3] [16.1] [7.0] [12.7] [51.7] [34.0] [6.0] [17.8] [2.5]

40 1/8 NPT

0.326

1/4 NPT 10-24

0.632 0.276 0.500 2.363 1.420

3/8-24 x 0.625

0.236 0.702 0.098

[8.3] [16.1] [7.0] [12.7] [60.0] [36.1] [6.0] [17.8] [2.5]

50 1/4 NPT

0.476

1/4 NPT 1/4-20

0.632 0.315 0.625 2.795 1.600

1/2-20 x 0.750

0.236 0.702 0.067

[12.1] [16.1] [8.0] [15.9] [71.0] [40.6] [6.0] [17.8] [1.7]

DIMENSIONS IN [ ] ARE mm

R PORT (BLOW)

Ø AA

Ø D1 Ø D2

Ø HØ G

A

A

B

B

F

C

F

Z THREAD

Y

E

W

E

2X THRU & C BORE FOR S

SOCKET HEAD CAP SCREW

(BOTH ENDS)

N PORT (RETRACT)

N PORT (EXTEND)

M

L

J + STROKE

CC + STROKE

K

U

BB

T WRENCH FLAT

0.219 [5.6] LONG

V WRENCH FLAT

0.189 [4.8] LONG

P

All dimensions are reference only unless specifically toleranced.

www.phdinc.com/bct

•

(800) 624-8511

8

CONTEXT02B

OPTIONS: SERIES BCT NEEDLE CYLINDER

This option attaches a mount plate with a 2" x 2" mounting hole pattern to

the cylinder and includes all fasteners. For Ø 32 and Ø 50 bore sizes only.

ATTACHED MOUNTING FLANGE

OPTION 2" x 2" HOLE PATTERN

W1

DIMENSIONS IN [ ] ARE mm

4X Ø L

A

D

Ø C

B

A

B

D

A

Ø C

B

A

B

Ø C

B

B

A

A

D

G

F

E

2X H THD

E

F

G

K

J

G

F

E

2X H THD

J

K

BCTx-1-32

4X Ø L

A

D

Ø C

B

A

B

D

A

Ø C

B

A

B

Ø C

B

B

A

A

D

G

F

E

2X H THD

E

F

G

K

J

G

F

E

2X H THD

J

K

BCTx-1-50

All dimensions are reference only unless specifically toleranced.

BORE

DIMENSIONS

A B C D E F G H THD J K L

32

2.500 2.000 1.247 0.375 0.224 0.125 0.375 — — — 0.281

[63.5] [50.8] [31.7] [9.5] [5.7] [3.2] [9.5] — — — [7.1]

50

2.750 2.000 1.247 0.375 0.375 0.125 1.562 1/4-20 1.625 0.338 —

[69.9] [50.8] [31.7] [9.5] [9.5] [3.2] [39.7] 1/4-20 [41.3] [8.6] —

www.phdinc.com/bct

•

(800) 624-8511

9

CONTEXT02B

NON-ROTATING SHAFT

EXTEND PORT

RETRACT PORT

BLOW PORT

K1

EE

P

NON-ROTATING SHAFT AND PORTS

MIRRORED OVER CENTERLINE OF CYLINDER

NON-ROTATING SHAFT

RETRACT PORT

EXTEND PORT

BLOW PORT

K1

P

EE

OPTIONS: SERIES BCT NEEDLE CYLINDER

This option mirrors the ports and non-rotating shaft over the centerline of

the cylinder to allow for additional machine clearance in some instances.

MIRROR PORT AND

NON-ROTATING SHAFT OPTION

H96

BORE

DIMENSIONS

K1 P EE

32 0.250 [6.4] 0.326 [8.3] 0.579 [14.7]

40 0.349 [8.9] 0.365 [9.3] 0.600 [15.2]

50 0.438 [11.1] 0.476 [12.1] 0.626 [15.9]

DIMENSIONS IN [ ] ARE mm

BORE

DIMENSIONS

P EE

32 0.326 [8.3] 0.579 [14.7]

40 0.365 [9.3] 0.600 [15.2]

50 0.476 [12.1] 0.626 [15.9]

DIMENSIONS IN [ ] ARE mm

BCT1

STANDARD UNIT

BCT2

STANDARD UNIT

BCT1

-H96 OPTION

BCT2

-H96 OPTION

All dimensions are reference only unless specifically toleranced.

NON-ROTATING SHAFT

EXTEND PORT

RETRACT PORT

BLOW PORT

EE

P

NON-ROTATING SHAFT AND PORTS

MIRRORED OVER CENTERLINE OF CYLINDER

NON-ROTATING SHAFT

RETRACT PORT

EXTEND PORT

BLOW PORT

P

EE

www.phdinc.com/bct

•

(800) 624-8511

10

CONTEXT02B

PARTS LIST & REPAIR KITS: SERIES BCT NEEDLE CYLINDER

KIT DESCRIPTION KIT NUMBER COLOR CODE*

Seal Kit Full unit description and -H9000

Repair Kit Full unit description and -H9010

* Color code designates parts to be included in kit

32 mm Bore Flange Kit

KIT DESCRIPTION KIT NUMBER COLOR CODE*

-W1 Option Full unit description and -H2000

* Color code designates parts to be included in kit

50 mm Bore Flange Kit

KIT DESCRIPTION KIT NUMBER COLOR CODE*

-W1 Option Full unit description and -H2000

* Color code designates parts to be included in kit

KEY PART DESCRIPTION 32 mm 40 mm 50 mm

1 Body Assembly Full unit description and -H2400

2 Outlet Rod Bushing 74049 73872 73873

3 Inlet Rod Bushing 88457 88519 73873

4 O-Ring Seal 3642-027-1 3642-028-1 3642-029-1

5 Outlet Rod Seal 18521-016 18521-016 18521-007

6 Inlet Rod Seal 18521-007 18521-007 18521-007

7 Retaining Ring 1987-073 1987-079 1987-085

8 Piston and Rod Assembly Full unit description and -H1000

9 Manifold Full unit description and -H6400

10 O-Ring Seal 1950-016-1 1950-016-1 1950-016-1

11 Hex Head Bolt 57021-025 57021-025 57021-025

12 Piston Seal 74042-008 74042-009 74042-010

13 Outlet Shock Pad 74029 74029 74030

14 Inlet Shock Pad 88452 88452 74030

15 Non-Rotating Shaft 17831-102 17831-102 17831-102

16 Non-Rotating Plate 88458 86738 86739

17 Nut 3204-084 3204-084 3204-084

18 Flange Sold as part of Flange Kit

19 Cylinder to Flange SHCS Sold as part of Flange Kit

20 Flange Mounting SHCS Sold as part of Flange Kit

1

13

8

BCT1 UNITS

14

11

9

15

BCT1 UNITS

BCT1 UNITS

BCT1 UNITS

17

15

16

BCT2 UNITS

BCT2 UNITS

8

BCT2 UNITS

-W1 OPTION

-W1 OPTION

-W1 OPTION

-W1 OPTION

-W1 OPTION

4

10

12

4

6

3

7

2

5

7

18

19

19

20

20

= LOCTITE 242 THREAD LOCKER

= LOCTITE R/C 680

= LUBRICANT PER FDA

REGULATION 21CFR 178.3570

BORE

ID

ID

www.phdinc.com/bcn

•

(800) 624-8511

11

CONTEXT02B

Needle Cylinder Replacement

Major Benefits

• Direct replacement for continuous extrusion blow molding

needle cylinders.

• Provides significantly longer life and reduces maintenance

and downtime.

• Internal needle orientation stud provides anti-rotational

movement and allows the needle to be infinitely adjustable

without increasing package length.

• Unique modular design provides a variety of design

configurations without sacrificing delivery and price.

• Male rod ends have piloted ends to reduce concentricity

issues with attached needles.

• Consult PHD for other custom needle cylinders and blow

molding actuators to meet your automation requirements.

3 port cylinder shown,

Consult PHD for 2 port

polyurethane lip seals

provide long life and

easy replacement

carbon-filled teflon composite

wear ring supports piston and

protects piston seals

stainless steel anti-rotational

stud provides adjustable

needle orientation

internal lubrication reservoir

with food grade lubricant

increases cylinder life

shock pads on extend and

retract reduce impact force

and increase cylinder life

engineered polymer

bushing is easy to replace

deep exhaust

channels increase

exhaust flow

optional mounting flanges

optional rod ends increase flow

rates and allow for easy and

precise needle attachment

BCN

Needle Cylinder

www.phdinc.com/bcn

•

(800) 624-8511

12

CONTEXT02B

1T13305825 25 TMO26x -ML --

TO ORDER SPECIFY:

ML#, Port Configuration,

Mounting Style, Design No.,

Bore Size, Stroke, and Options.

MOUNTING STYLE

N - Nose Mount

T1 - Flange Style 1

U - Universal Mount

DESIGN NO.

1 - Imperial

5 - Metric

STROKE

19 - 19 mm (0.748 in)

26 - 26 mm (1.024 in)

BORE SIZE

25 mm

PORT CONFIGURATION

3 - 3 Port, 12 mm Rod

5 - 3 Port, 10 mm Rod

Consult PHD for 2 Port units

OPTIONS

T30 - Female Rod End

TMO - Male Rod End - High Flow

Extended thread length

TRO - Oversize Female Rod End

Other configurations are available. Contact PHD for options.

ORDERING DATA: SERIES BCN NEEDLE CYLINDER

ENGINEERING DATA: SERIES BCN NEEDLE CYLINDER

SPECIFICATIONS IMPERIAL (1) METRIC (5)

TYPE Blow Mold Needle Cylinder

SERIES BCN

BORE SIZE 0.984 in 25 mm

BORE AREA 0.761 in² 4.91 cm²

THEORETICAL OUTPUT 66.2 lb @ 87 psi 294.5 N @ 6 bar

OPERATION Double Acting

OPERATING PRESSURE RANGE 7.5 - 150 psi 0.5 - 10 bar

AMBIENT TEMPERATURE -18.4° to 176° F -28° to 80° C

LUBRICATION; FOOD GRADE FDA Regulation 21CFR 178.3570

PORT SIZE 1/8 NPT [1/8 BSPP]

STROKE TOLERANCE +0.059/-0.000 +1.5/-0.000

WEIGHT @ 25 mm STROKE 1.1 lb 0.50 kg

BUMPERS Polyurethane, Extend, and Retract

HEAD Anodized Aluminum

CYLINDER BODY Anodized Aluminum

PISTON ROD Chrome Plated Stainless Steel

ROD BEARING Engineered Polymer

PISTON & ROD SEALS Polyurethane

PISTON Hardcoated PTFE Aluminum

www.phdinc.com/bcn

•

(800) 624-8511

13

CONTEXT02B

3 PORT CONFIGURATION

2X M4 x 0.7 x 0.472 DP

5/16-24 THD (DESIGN 1)

M8 x 1.25 THD (DESIGN 5)

3X 1/8 NPT (DESIGN 1)

3X BSPP PORT (DESIGN 5)

BLOW PORT

11 mm WRENCH FLAT

ROD END TO ACCEPT

5/32 NEEDLE

1.407

[35.7]

EXTENDED

0.341

[8.7]

D

C

B

A

0.843

[21.4]

0.863

[21.9]

1.250

[31.8]

0.122

[3.1]

0.125

[3.2]

1.614

[41]

0.750

[19.1]

0.159

[4]

0.141

[3.6]

0.317 0.001

[8.052

0.025]

2X .375

[9.5]

Ø .998

[25.3]

4X Ø .281

[7.1]

1.250

[31.8]

2X .325

[8.3]

.114

[2.9]

2X .189

[4.8]

.100

[2.5]

.125

[3.2]

.375

[9.5]

T1 Mounting Style

T2 Mounting Style

1.500

[38.1]

1.930

[49]

1.500

[38.1]

1.930

[49]

62

ϒ

2X .375

[9.5]

Ø 1.250

[31.8]

Ø

.998

[25.3]

3X Ø .281

[7.1]

1.398

[35.5]

2X 45

ϒ

6X .325

[8.3]

6X .114

[2.9]

6X .189

[4.8]

.100

[2.5]

.125

[3.2]

.375

[9.5]

T3 Mountng Style N Mounting Style

2.500

[63.5]

2.000

[50.8]

2X .375

[9.5]

Ø 1.247

[31.7]

1.250

[31.8]

4X

Ø .281

[7.1]

.375

[9.5]

.125

[3.2]

.100

[2.5]

2X .189

[4.8]

2X .114

[2.9]

.325

[8.3]

1.250

[31.8]

Ø 1.614

[41]

.375

[9.5]

2X .114

[2.9]

2X .189

[4.8]

2X .325

[8.3]

Ø .871

[22.1]

.125

[3.2]

.750

[19.1]

Ø .6251

[15.9]

2X .375

[9.5]

Ø

.998

[25.3]

4X Ø .281

[7.1]

1.250

[31.8]

2X .325

[8.3]

.114

[2.9]

2X .189

[4.8]

.100

[2.5]

.125

[3.2]

.375

[9.5]

T1 Mounting Style

T2 Mounting Style

1.500

[38.1]

1.930

[49]

1.500

[38.1]

1.930

[49]

62ϒ

2X .375

[9.5]

Ø

1.250

[31.8]

Ø

.998

[25.3]

3X

Ø

.281

[7.1]

1.398

[35.5]

2X 45

ϒ

6X .325

[8.3]

6X .114

[2.9]

6X .189

[4.8]

.100

[2.5]

.125

[3.2]

.375

[9.5]

T3 Mountng Style N Mounting Style

2.500

[63.5]

2.000

[50.8]

2X .375

[9.5]

Ø 1.247

[31.7]

1.250

[31.8]

4X

Ø .281

[7.1]

.375

[9.5]

.125

[3.2]

.100

[2.5]

2X .189

[4.8]

2X .114

[2.9]

.325

[8.3]

1.250

[31.8]

Ø

1.614

[41]

.375

[9.5]

2X .114

[2.9]

2X .189

[4.8]

2X .325

[8.3]

Ø .871

[22.1]

.125

[3.2]

.750

[19.1]

Ø .6251

[15.9]

DIMENSIONS: SERIES BCN NEEDLE CYLINDER

CONFIGURATION STROKE Ø A B C D

3

19, 26, 30 0.472 [12] 4.632 [118] 4.160 [106] 1.501 [38]

35, 39 0.472 [12] 5.537 [141] 5.065 [129] 2.052 [52]

5

19, 26, 30 0.394 [10] 4.632 [118] 4.160 [106] 1.501 [38]

35, 39 0.394 [10] 5.537 [141] 5.065 [129] 2.052 [52]

B THREAD X C DP MIN

D

A

B THREAD x C DP MIN.

D

A

TR0 - Oversize

Female Rod End

T30 - Female Rod End TM0 - High Flow

Male Rod End

0.190

[4.8]

5/16-24 THD (DESIGN 1)

M8 x 1.25 THD (DESIGN 5)

0.172

[4.4]

ROD END TO ACCEPT

3/16 NEEDLE

0.843

[21.4]

0.750

[19.1]

CONFIGURATION Ø A B C D

3

0.472 3/8-24 0.687 1.507

[12] [M10 x 1.5] [17.4] [38.3]

5

0.394 5/16-24 4.160 1.407

[10] [M8 x 1.0] [105.7] [35.7]

CONFIGURATION Ø A B C D

3

0.472 5/16-24 0.687 1.407

[12] [M8 x 1.0] [17.4] [35.7]

All dimensions are reference only unless specifically toleranced.

www.phdinc.com

•

(800) 624-8511

14

CONTEXT02B

KNOCKOUT

NEEDLE

OTHER NEEDLE & KNOCKOUT CYLINDERS

ML304949

ML310701

ML306733

More needle & knockout

actuators are available.

PHD has designed direct replacements for various continuous

extrusion blow molding needle and knockout cylinders.

In addition, PHD offers the service of our Unlimited Unique Solutions

group. With Unique Solutions, we have the ability to design specific

needle and knockout cylinder replacements that will fit your particular

machine. Benefits include significantly longer life and reduced

maintenance and downtime. PHD unique modular designs provide a

variety of configurations without sacrificing delivery or price.

PHD needle cylinders offer an internal needle orientation stud which

provides anti-rotational movement and allows the needle to be

infinitely adjustable without increasing package length.

Male rod ends have piloted ends to reduce concentricity issues with

attached needles.

Optimized mold-mounted knockout cylinder designs meet your unique

needs while eliminating mechanical or machine mounted knockouts,

thus improving the process and product consistency.

Contact PHD for more needle and knockout

cylinder solutions.

• Most quotes delivered within eight working hours

• Dedicated application assistance

• 24 hours a day, 7 days a week service

• Fast delivery and competitive pricing

• CAD files available prior to ordering

• Geared towards short-run requests

• All units receive an “ML” number when

ordered. This number, along with all

specifications, is kept on permanent

record at PHD for future reference

and reorders.

PHD Series CV Style

PHD Series AV Style

UNIQUE SOLUTIONS

®

To request a free brochure, visit

www.phdinc.com/resources/inforequest/

Special Rod Style

www.phdinc.com

•

(800) 624-8511

15

CONTEXT02B

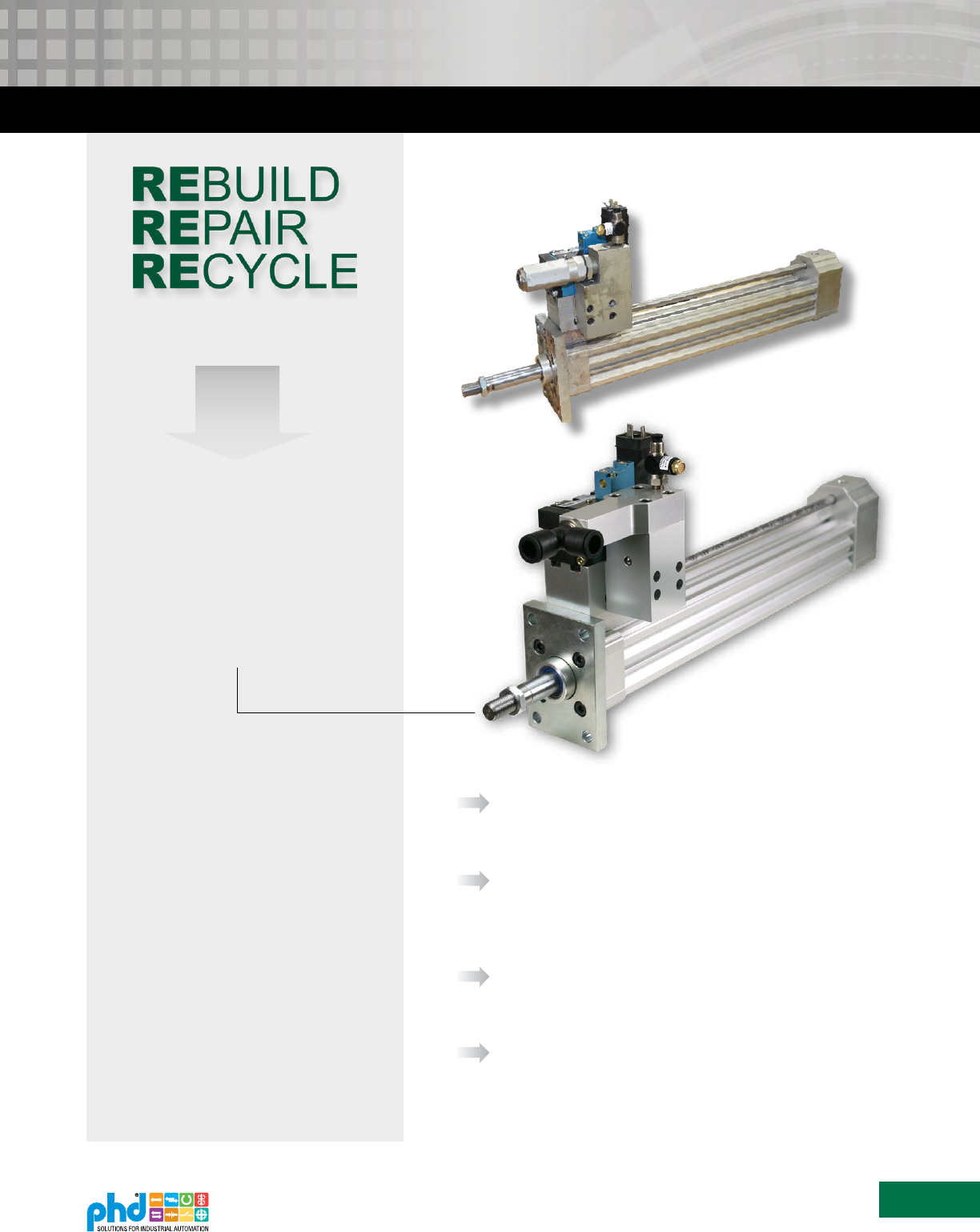

Rebuild Program

Plastic Packaging Components such

as Stretching Cylinders, Transfer

Arms, Blow Nozzles, Filler Cylinders,

Slip Sheet Grippers, and Eject Slides

are rebuildable.

Get a 12 Month

“Like New”

Warranty

PHD’s rebuild program can save

your facility training, additional work

load, possible tool requirements,

and facility space to perform the

rebuilds. In addition, you will receive

a 12 month “like new” warranty.

REBUILD IT

YOURSELF OR

ALLOW PHD?

PHD’s Rebuild Program refurbishes

your existing PHD products with all

new wear items.

Rebuilt units offer the same PHD quality

that you’re used to, but for a fraction

of the cost of a new unit, reducing your

total cost of ownership.

Rebuilt units are placed back into service,

thus reducing your total cost and saving

valuable components from scrap.

All PHD factory rebuilt units receive a

12 month “like new” warranty.

Return your old

units for rebuilding

Before:

After: This stretching

cylinder was rebuilt and

returned to service.

www.phdinc.com

•

(800) 624-8511

16

CONTEXT02B

BCK Stretching

Cylinders

‘K’ Style spare components

Simplied pneumatic system

Eject Cylinders

ML309880 and ML310656

‘K’ Style spare components

Provides rapid repeatable ejection

function due to MAC valve design

and PHD cylinder.

High kinetic energy capacity

Provides faster delivery times than

OEM product

In many cases lower cost solution

than OEM product

Intended for high speed

part rejection

Transfer Arm Head

ML311628

‘K’ Style spare component

‘K’ STYLE

‘S’ STYLE

Slip Sheet Gripper

Modular assembly consisting of

a clamp, slide, and transition plate

Clamp provides a wide opening

so slip sheets are not missed

Quick installation and

easy maintenance

Fill Line Eject Slide

ML309590

Repeatable ejection

High kinetic energy capacity

Uses proven PHD thruster

slide technology

Cam Follower

Wheels

Competitive pricing

Longer life than OEM

Available in variety of material

BCS Stretching

Cylinders

‘S’ Style Series1, Series2, and

Universal spare components

X27 PHD check valve option

BCZ Nozzle

Cylinders

‘S’ Style Series2 and Universal

spare components

Valve manifold assembled

to cylinder available as standard

BST Transfer Arm Preferential Head

BST1

Transfer Arm

‘S’ Style Series1 spare component

Signicantly more robust and

precise than other transfer arms

Designed to operate over

20 million cycles

BST2

Transfer Arm

‘S’ Style Series2 spare component

Vertical height adjustment

eliminates need for shims

Designed to operate over

20 million cycles

Preform/

Bottle Eject Slide

‘S’ Style Series2 spare component

Consistent preform/bottle ejection

Minimizes stress on

transfer arm jaws

To request more literature, visit

www.phdinc.com/resources/inforequest/

OTHER SOLUTIONS

6/19 10959