World Headquarters

Victrex plc

Victrex Technology Centre

Hillhouse International

Thornton Cleveleys

Lancashire FY5 4QD

United Kingdom

Tel: +44 (0) 1253 897700

Fax: +44 (0) 1253 897701

Email: [email protected]

Americas

Victrex USA Inc.

3A Caledon Court

Greenville, SC 29615

USA

Tel: + (1) 800 VICTREX

Tel: + (1) 864 672 7335

Fax: + (1) 864 672 7328

Email: [email protected]

Europe

Victrex Europa GmbH

Hauptstr. 11

65719 Hofheim/Ts.

Germany

Tel: + (49) 6192 964949

Fax: + (49) 6192 964948

Email: [email protected]

Asia-Pacific

Victrex plc

Hanai Building 6F

1-2-9 Shiba Koen

Minato-Ku

Tokyo 105 -0011

Japan

Tel: +(81) 35777 8737

Fax: +(81) 35777 8738

Email: [email protected]

Victrex plc believes that the information contained in this brochure is an accurate description of the typical characteristics and/or uses of the product or

products, but it is the customer's responsibility to thoroughly test the product in his specific application to determine its performance, efficacy and safety

for each end-use product, device or other application. Suggestions of uses should not be taken as inducements to infringe any particular patent. The

information and data contained herein are based on information we believe reliable. Mention of a product in this documentation is not a guarantee of

availability. Victrex plc reserves the right to modify products, specifications and/or packaging as part of a continuous program of product development.

©Victrex USA 604/1.5M

▲ World Headquarters

▲ Sales Offices

Distributors

www.victrex.com

A Global Company

Victrex plc is an innovative world-leader in high performance materials.

It has manufacturing plants and research facilities in the UK, and sales

and distribution centers serving more than 30 countries worldwide

▲

▲

▲HQ

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲▲

▲

▲

▲

▲

▲

▲

A comprehensive review of the processing

guidelines of VICTREX

®

PEEK

™

high performance polymer

PROCESSING GUIDE

www.victrex.com

1

TABLE OF CONTENTS

Page

INTRODUCTION

Process Preparation and Handling of VICTREX PEEK . . . . . . . . . . . . . . . . . . .3

Drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Re-Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Thermal Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Processability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Purging Injection Molders and Extruders . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

An Overview of Start-Up Purging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

An Overview of Shut-Down Purging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Materials of Construction for VICTREX PEEK Processing Equipment . . . . . . .5

INJECTION MOLDING

Machine Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Barrel Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Barrel Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Nozzles and Shut-Off Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Injection and Clamping Pressures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Screw Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Mold Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Mold Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Melt Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Gating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Hot Runner Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Shrinkage and Tolerances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Injection Pressures and Screw Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

EXTRUSION

Machine Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Barrel Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Barrel Capacity and Residence Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Screw Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Wire and Cable Coating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Die and Crosshead Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Wire and Cable Crystallinity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Extruder Size and Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Sheet Manufacture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Die Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Thin Film and Sheet Crystallinity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Monofilament . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Monofilament Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

COMPRESSION MOLDING

Basic Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Equipment Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Compression Molding Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2

Page

POWDER COATING

Electrostatic Spray and Fluidized Bed Coating . . . . . . . . . . . . . . . . . . . . . . . . .15

Dispersion Spray Coating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

FINISHING OPERATIONS

Machining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Prototype Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Annealing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

An Overview of Annealing for Optimum Crystallinity . . . . . . . . . . . . . . . . . .16

An Overview of Annealing to Remove Stresses . . . . . . . . . . . . . . . . . . . . . . . .16

An Overview of Annealing to Remove Thermal History and Shrinkage . . . .16

Adhesive Bonding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Adhesive Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Surface Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Welding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Vacuum Metallization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Coloring VICTREX PEEK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

POLYMER SPECIFICATIONS AND APPROVALS

Aerospace/Miltary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Automotive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Flammability Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Food and Beverage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Industrial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Wire and Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

150

200 250 300 350 450400

Shear Viscosity / Pa s

Shear Viscosit

y

/ Poise

10

07

10

06

10

05

10

04

10

06

10

05

400 500 600 700 800

10

04

10

03

Tem

p

erature / °C

Temperature / °F

VICTREX 450G

POLYAMIDE-IMIDE

POLYCARBONATE

NYLON 6/6

LDPE (MFI 2)

RIGID PVC

SOFT PVC

3

INTRODUCTION

VICTREX PEEK is a linear aromatic semi-crystalline ther-

moplastic. It is widely regarded as the highest perfor-

mance material capable of being processed on conven-

tional thermoplastic equipment.

VICTREX PEEK and compounds are supplied in the form

of pellets, powder or ultrafine powder. Pellets are gen-

erally recommended for injection molding, extrusion,

monofilament and wire coating operations. Powder is

used for extrusion compounding, while fine powders

are generally used for coating processes and compres-

sion molding.

PROCESS PREPARATION AND HANDLING OF

VICTREX PEEK

VICTREX PEEK is supplied in a sealed polyethylene bag

inside a heavy-duty cardboard box or a pallet sized box.

It is strongly recommended that the materials remain

sealed in the original packaging during subsequent

transportation and storage. When material is required,

the boxes should be opened in a clean environment and

care taken to avoid contamination. Any remaining mate-

rial should be re-sealed as soon as possible and stored in

a dry place. As long as Victrex raw materials are kept

sealed, dry, in their original box and are not left in direct

sunlight they may be stored in excess of 10 years.

DRYING

Although VICTREX PEEK materials are supplied nomi-

nally dry, the pellet form of the polymer typically

absorbs 0.5% w/w atmospheric moisture. For best

results, powder and pellets should be dried to less than

0.02% w/w moisture (dew point of -40°). This is easily

achieved by placing the material in an air circulating

oven for a minimum of 3 hours at 150°C (302°F) or 2

hours at 160°C (320°F). The material should be spread

out in trays in layers about 2.5 cm (1 in) deep. Care

must be taken during drying or any other secondary

handling operations not to introduce sources of conta-

mination. Do not dry other materials in the same oven

as VICTREX PEEK unless there is suitable isolation from

extraneous contamination.

RE-WORK

It is common practice with most thermoplastic materials

to re-work ground runners and sprues with virgin

material to enhance production efficiency. VICTREX

PEEK may also be re-worked in this way. However, the

level of re-work may influence the quality of the mold-

ing and increase the chances of cross-contamination.

Extraneous material, even at low levels, will have a seri-

ous effect on molding quality due to the high process-

ing temperatures used for VICTREX PEEK. It is recom-

mended that re-work be restricted to a maximum of

30% w/w for unfilled polymer and 10% w/w for filled

compounds.

THERMAL STABILITY

VICTREX PEEK and compounds are thermally stable at

processing temperatures. If any delay in melt processing

causes the polymer residence time to increase up to

one hour, the material can be maintained at 360°C

(680°F) with no appreciable degradation. However, if

the delay is more than one hour, the barrel tempera-

tures should be reduced to 340°C (644°F). VICTREX PEEK

materials are stable at this temperature for several

hours, although barrel temperatures should be raised

again to continue processing. If the delay is likely to

result in a polymer residence time greater than 3 hours,

the barrel should be purged (see Purging Injection

Molders and Extruders, page 4). After any increase in

residence time, it is advisable to discard the initial

moldings produced on re-starting.

PROCESSABILITY

The melting temperature of VICTREX PEEK is 343°C

(649°F). The melt is stable and workable with most con-

ventional process equipment between 360°C and 400°C

(680°F and 752°F). A comparative plot of melt viscosity

versus temperature (over the stable melt range) for a

range of conventional

engineering polymers is shown

in Figure 1.

Figure 1: Shear Viscosity Versus Temperature for a Range

of Engineering Thermoplastics

The data in Figure 1 show that, although VICTREX

PEEK has one of the highest processing temperatures,

typical viscosities of VICTREX 450G at those tempera-

tures are similar to rigid PVC or polycarbonate melts.

The viscosity has been shown to be shear rate and

temperature sensitive. Polymer melts are usually clas-

sified by measuring their viscosity over a range of

shear stresses or shear rates at constant temperature.

The viscosities of VICTREX PEEK grades are plotted

versus shear stress over two decades of shear rate in

Figures 2, 3 and 4.

The upper family of curves in Figure 2 represents typical

melt viscosities of VICTREX 450G at various temperatures.

The middle family of curves represents typical melt viscosities

of VICTREX 381G and the lower curve represents the viscosi-

ty behavior of VICTREX 150G/151G. From this data it is clear

that the effect of increasing temperature is to reduce the

viscosity of the melt. These values of melt viscosity are used

to classify natural VICTREX PEEK into low (VICTREX 150G/

151G), medium (VICTREX 381G) and standard (VICTREX

450G) viscosity grades.

PURGING INJECTION MOLDERS AND

EXTRUDERS

VICTREX PEEK and compounds should ideally be

processed on completely clean equipment. For extrud-

ers and injection molders this will mean removing the

screw and barrel for cleaning. If the removal of the

screw and barrel are not possible, then purging is

essential. The ideal purge materials are those which are

stable at 380°C (716°F), i.e., polyethersulphone and

polyetherimide. Low MFI polyethylene = 0.3 MFI may

Shear Viscosity / Pa s

Shear Viscosit

y

/ Poise

10

05

10

04

10

03

10

02

10

06

10

05

10

04

10

04

10

03

10

02

10

01

10

01

10

02

Shear Stress / psi

Shear Stress / Pa

VICTREX 450G

VICTREX 150/151G

1000s

-1

100s

-1

VICTREX 381G

400°C (752°F)

380°C (716°F)

360°C (680°F)

{

{

Figure 2: Shear Viscosity Versus Shear Stress

for Natural VICTREX PEEK

be used at such temperatures. However, these materials

will partially degrade and adequate provision must be

made for the resultant fumes. Also, there are commer-

cially available purging compounds which are designed

to be used at VICTREX PEEK processing temperatures.

Consult the purge material manufacturer's Material

Safety Data Sheets (MSDS) for any purge material used.

AN OVERVIEW OF START-UP PURGING

All traces of other polymers must be removed from the

equipment before VICTREX PEEK materials are processed.

(a) Purging should take place at the temperature at

which the material to be removed is normally

processed.

(b) Purge is fed through the screw until there is no

visible trace of the material to be removed.

(c) Stop purge feeding and allow the screw to empty.

(d) Set the barrel heaters to reach VICTREX PEEK pro-

cessing temperatures.

(e) When processing temperatures are obtained, feed

VICTREX PEEK into the screw and extrude until a

clean melt develops.

AN OVERVIEW OF SHUT-DOWN PURGING

VICTREX PEEK must be removed from processing

equipment before other materials are processed.

(a) Empty the barrel of VICTREX PEEK materials.

(b) Feed purge through the screw until there is no

visible trace of the material.

(c) Reduce the settings of all the barrel zones to a

sta ble purge temperature (e.g., 250°C (482°F)).

(d) Continue to feed purge into screw until the actual

barrel temperature is below 300°C (572°F).

(e) Stop purge feeding and allow the screw to empty.

Note: This advice is based on our general experience with

typical processing equipment. Special care must be

taken with larger extruders or injection molders as resi-

dence times are increased.

Shear Viscosity / Pa s

Shear Viscosit

y

/ Poise

10

05

10

04

10

03

10

02

10

06

10

05

10

04

10

04

10

03

10

02

10

01

10

01

10

02

Shear Stress / psi

Shear Stress / Pa

VICTREX

450GL30

VICTREX

150GL30

1000s

-1

10s

-1

400°C (752°F)

380°C (716°F)

360°C (680°F)

{

100s

-1

Figure 3: Shear Viscosity Versus Shear Stress for 30% Glass

Fiber Filled VICTREX PEEK

Figure 4: Shear Viscosity Versus Shear Stress for 30%

Carbon Fiber Filled VICTREX PEEK

Shear Viscosity / Pa s

Shear Viscosit

y

/ Poise

10

05

10

04

10

03

10

02

10

06

10

05

10

04

10

04

10

03

10

02

10

01

10

01

10

02

Shear Stress / psi

Shear Stress / Pa

VICTREX

150CA30

VICTREX

450CA30

1000s

-1

10s

-1

100s

-1

400°C (752°F)

380°C (716°F)

360°C (680°F)

{

4

MATERIALS OF CONSTRUCTION FOR

VICTREX PEEK PROCESSING EQUIPMENT

The problem of machine wear is common to all engi-

neering thermoplastics and can be particularly severe

when extruding or injection molding fiber filled materi-

als. To minimize wear in such processes, screws, dies and

barrels should be hardened. The most common way of

hardening tool steel is to coat with nitride. This tech-

nique provides the surface hardness necessary to resist

excessive wear from the melt. Care must be taken to

ensure that the VICTREX PEEK does not cool and solidi-

fy in contact with the nitride coating. The bond

between the polymer and the nitride coating is often

strong enough to lift the layer from the steel substrate.

The following steels are generally recommended for the

construction of process equipment suitable for VICTREX

PEEK:

• D2 Tool Steel (A martensitic chromium tool steel)

• WEXCO 777

• CMP-10V

• CMP-9V

• S32 219 Stainless Steel

Although not generally required, corrosion resistant

and bi-metallic screws and barrels have proved satisfac-

tory in service. Avoid copper alloys because they can

cause degradation at VICTREX PEEK processing tempera-

tures.

The surface finish of metallic components which are

used in melt transportation should be smooth and high-

ly polished. Increasing the surface roughness of these

components causes the melt to adhere locally to the

metal, which increases residence time and disturbs poly-

mer flow.

5

INJECTION MOLDING

Most standard reciprocating screw injection molding

machines are capable of molding VICTREX PEEK and

compounds. Complex high performance components

can be readily mass produced without the need for

annealing or conventional machining.

MACHINE DESIGN

VICTREX PEEK and compounds based on VICTREX PEEK

can be readily injection molded. However, due to the

high melt temperature, certain design and process vari-

ables need to be considered. These are listed below.

BARREL TEMPERATURES

In order to successfully mold VICTREX PEEK materials,

the cylinder heaters connected to the barrel of the

injection molder must be able to reach 400°C (752°F).

Most injection molding machines are capable of these

temperatures without the need for modification. In the

exceptional cases where modification is required, it is a

simple task to install higher temperature range con-

trollers and ceramic heaters.

In order to achieve correct hopper feeding, the feed

throat should be maintained between 70°C and 100°C

(158°F and 212°F). Thermal conduction along the screw

and barrel to the hopper may reduce the feed efficien-

cy. Thermal control in the feed section may be achieved

by water cooling, but care must be taken to maintain

the rear zone temperature.

BARREL CAPACITY

Residence times must be kept as short as possible due

to the high processing temperatures of VICTREX PEEK.

Ideally, the barrel capacity should be between 2 and 5

times the total shot weight including sprue and run-

ners. If it is necessary to mold VICTREX PEEK on a

machine which has a large number of shots in the bar-

rel, then the rear zone temperature may be reduced by

10°C to 20°C (50°F to 68°F) below the recommended

temperature settings (see Troubleshooting, page 9).

NOZZLES AND SHUT-OFF SYSTEMS

The nozzle of the barrel is in contact with the sprue-

bush for a high percentage of the total cycle time dur-

ing normal operations. The temperature of the sprue-

bush is considerably lower than that of the melt and

the nozzle. VICTREX PEEK has a sharp melting point

and will solidify quickly if the melt temperature is

allowed to fall below 343°C (649°F). Therefore, it is

important to ensure that an adequately large heater is

fitted to the nozzle to prevent freeze-off and “cold

slugging.” Extended nozzles are not generally recom-

mended for use with VICTREX PEEK because they

increase the likelihood of solidification in the nozzle.

Over the recommended process temperatures, the vis-

cosity of VICTREX PEEK is generally still high enough to

allow an open nozzle system. Shut-off nozzles are not

recommended because they frequently contain melt

“dead spots” and restrict injection pressures. If excessive

die drool is encountered, minor melt decompression can

be employed in the process cycle.

INJECTION AND CLAMPING PRESSURES

The injection pressures required for correct component

molding are system dependent. However, in general,

injection pressures rarely exceed 14 MPa (2030 psi) with

secondary holding pressures of 10 MPa (1450 psi).

The projected area of the molding and runner deter-

mines the clamp force required to prevent the mold

from opening under maximum injection pressure. This

typically corresponds to 50-80 MPa (3.6-5.8 Tons in

-2

) for

natural VICTREX PEEK and 65-140 MPa (4.7-10 Tons in

-2

)

for the fiber reinforced compounds. However, parts

6

with thin sections and long flow lengths will require

higher clamping pressures than those with thick sec-

tions and short flow lengths.

SCREW DESIGN

Most general purpose and “nylon” type screws are suit-

able for processing VICTREX PEEK grades. Two such

screws with appropriate length to diameter (L/D) ratios,

are shown in Figure 5.

The minimum recommended L/D ratio screw is 16:1. L/D

ratios between 18:1 and 24:1 are preferred. Long feed sec-

tions are required to prevent compaction of unmelted pel-

lets in the compression section of the screw. The compres-

sion ratio should be between 2:1 and 3:1. Check rings

must always be fitted to the screw tip to ensure develop-

ment of a full and sustained injection pressure. Ring clear-

ance should allow for an unrestricted flow of material on

forward movement of the screw. This typically corre-

sponds to a 3 mm (0.12 in) clearance from the screw tip

diameter for a medium size molding machine.

MOLD DESIGN

VICTREX PEEK and compounds can be readily processed

using many existing molds. However, certain design crite-

ria must be met for successful molding. It is recommend-

ed that the mold cavities and cores have Rockwell hard-

ness 52-54 at VICTREX PEEK processing temperatures.

Contact your local Victrex representative for more infor-

mation.

MOLD TEMPERATURE

The recommended mold temperature range for process-

ing VICTREX PEEK is from 175°C to 205°C (350°F to

400°F). These temperatures are the surface temperature

of the mold and not the set temperature of the control

unit. If an oil heater is used it would be normal for the

set point on the controller to be somewhat higher due

to heat losses (set points of 260°C (500°F) are typical).

Electric cartridge heaters may be used but it is difficult

to control the temperature locally, leading to problem-

atic hot spots in large tools.

These temperatures have been found to give good

mold filling and a high level of crystallinity within the

moldings. Lower mold temperatures will tend to give

moldings with non-uniform color and dark edges/cor-

ners due to decreased crystallinity (amorphous material)

at the molding surface.

It is possible to crystallize amorphous VICTREX PEEK

moldings by using an annealing process subsequent to

molding, however this may lead to distortion and

dimensional changes. Every effort should be made to

mold components with the highest possible crystallinity

by using the mold temperatures recommended above.

MELT FLOW

Sprues should be at least 4 mm (0.16 in) thick and as

short as possible. Larger diameter sprues have been

shown to aid filling in complex molds which feature

long flow lengths and thin sections. VICTREX PEEK com-

ponents require a minimum taper angle of 2° on the

sprue and on the inside of the sprue-bush for successful

de-molding. When possible, a “cold-slug” well should

be incorporated into the sprue design.

VICTREX PEEK molds require circular or trapezoidal run-

ners with large section thickness. Melt flow paths

should be kept as short as possible and sharp changes

of direction should be avoided.

The success of molding components with thin flow sec-

tions is a function of thermal, geometrical and pressure

variables. An approximate guide to the effects of sec-

tion thickness on the resultant flow length is shown in

Figure 6.

The data in Figure 6 were derived from measurements

made on a spiral flow mold with an injection pressure

of 140 MPa (20,300 psi). It is not recommended to

design molds for natural VICTREX PEEK with a section

thickness of less than 1 mm (0.04 in) or 1.5 mm (0.06 in)

for reinforced grades.

Figure 5: Screw Types Recommended for the Processing of

VICTREX PEEK

0

100

200

300

400

500

600

700

800

1 mm (0.04 in) 2 mm (0.08 in) 3 mm (0.12 in)

Channel Depth

0

5

10

15

20

25

30

Barrel Temperature 360°C (680°F)

Barrel Temperature 385°C (725°F)

Flow Length / mm

Flow Len

g

th / in

Figure 6: Flow Length Versus Barrel Temperature for

Natural VICTREX 450G

metering

section

(6 L/D)

metering

section

(5 L/D)

screw tip

screw tip

feed

section

(12 L/D)

feed

section

(9 L/D)

comp.

section

(6 L/D)

comp.

section

(2 L/D)

GATING

The size and style of gating appropriate for a mold will

depend on the melt volume, the number of cavities and

the component geometry required. Most gate designs

are suitable for VICTREX PEEK molding although long

thin flow sections should be avoided. Gates should be

as large as possible. The minimum recommended gate

diameter or thickness is 1 mm (0.04 in) for natural

VICTREX PEEK and 2 mm (0.08 in) for compounds. Sprue

gates should be between 1 - 1.5 times the thickness of the

molding. Submarine or tunnel gates should only be con-

sidered for thin wall or small parts. Advice on suitable

gates for molding VICTREX PEEK is available on request

from Victrex.

HOT RUNNER SYSTEMS

Hot runners and hot sprue bushings have been used

successfully around the world for the injection molding

of VICTREX PEEK for over 15 years. All materials in the

Victrex range are suitable for use with hot runners and

sprues.

The advantages of hot runner systems and hot sprue

bushings are:

• The weight of the sprue and runner system is reduced.

• With direct gated thick walled shapes hot sprue bush-

ings can offer a significant advantage in packing out

thick sections.

• The molding window is often larger.

• While cold runner systems can be recycled, there are

potential issues related to contamination and the

quantity of regrind that can be tolerated within a

molding.

The disadvantages of hot runner and hot sprue systems

are:

• The initial capital costs of such tooling systems are

higher.

• Purging hot runner systems can result in major conta-

mination problems.

• Overall maintenance costs for a hot runner tool are

higher than for a cold runner tool.

If considering the use of hot runner systems the follow-

ing advice is offered:

• Always ensure that the runner system has external

heating with no internal flow restrictions.

• The runner system needs to be able to operate, con-

sistently, at 450°C (842°F).

• Nozzle tips should be generous and sited on the compo-

nent surface, pin gating is not recommended.

• The temperature control of the individual runners needs

to be very good in order to keep the tool balanced.

• Due to the high operating temperatures of hot run-

ner molds for VICTREX PEEK and the consequent ther-

mal expansion it is advisable to have the ‘hot’ section

of the tool manufactured by the hot runner supplier.

7

• For tight toleranced parts it is recommended that the

tool should be a maximum of 4 to 8 cavities.

• As with any process, time is required for a process to

stabilize. The use of hot runners and sprues may lead

to an increase in the settling time of the process.

Purging a hot runner system can lead to problems due

to dead-spots in the material flow path. If using hot

runners it is advisable not to purge the runners with

anything other than VICTREX PEEK. When the produc-

tion run is complete, the runner temperatures should

be reduced in line with the values quoted in our litera-

ture for the barrel of the molding machine.

The cleaning of hot runners can present difficulties and

it is sensible to discuss this with the supplier of the hot

runner system. However, it must be emphasized that

each tool design will have special requirements and the

runner system must be appropriate to the specific tool

design. For further information please contact your

local Victrex representative.

SHRINKAGE AND TOLERANCES

Like all injection moldable thermoplastics, VICTREX

PEEK components shrink while cooling in the mold.

Shrinkage of VICTREX PEEK moldings is due to thermal

contraction and the development of crystalline regions

within the cooling melt.

VICTREX PEEK and compounds are semi-crystalline ther-

moplastics. Many of the outstanding physical properties

which are associated with these materials are a function

of the degree of crystallinity. The level of crystallinity is

highly influenced by melt and mold temperatures.

Using the recommended injection molding conditions

(see Operating Conditions, page 8), VICTREX PEEK parts

should be nominally 30% crystalline.

The mold shrinkage of all VICTREX PEEK grades was eval-

uated using pre-dried materials in a circulated air oven

overnight at 120°C (248°F), as per Victrex recommenda-

tions. The materials were molded into a variable thickness

150 mm x 150 mm (6 in x 6 in) single cavity plaque mold.

Gating was via a fan gate of 2.5 mm (0.1 in) thickness

and 1 mm (0.04 in) land length. Both sides of the mold

were heated with cartridge heaters. Plaques were made

on a 150 tonne injection molding machine. All process

conditions were set according to the grade being inject-

ed following our normal processing procedures. Three

plaques per material/temperature/thickness were chosen

at random during short runs of each material. Three

width and three length measurements were taken from

each plaque approximately 1 week after molding. The

dimensions of the corresponding cavities were measured

when cold. To investigate the effects of a typical post

8

mold treatment two samples for each material/ tempera-

ture/thickness were annealed in an oven set at 220°C

(428°F) for 3 hours, samples were measured on their

return to room temperature. Samples molded with a tool

temperature of 210°C (410°F) were used to give the max-

imum mold shrinkage following annealing.

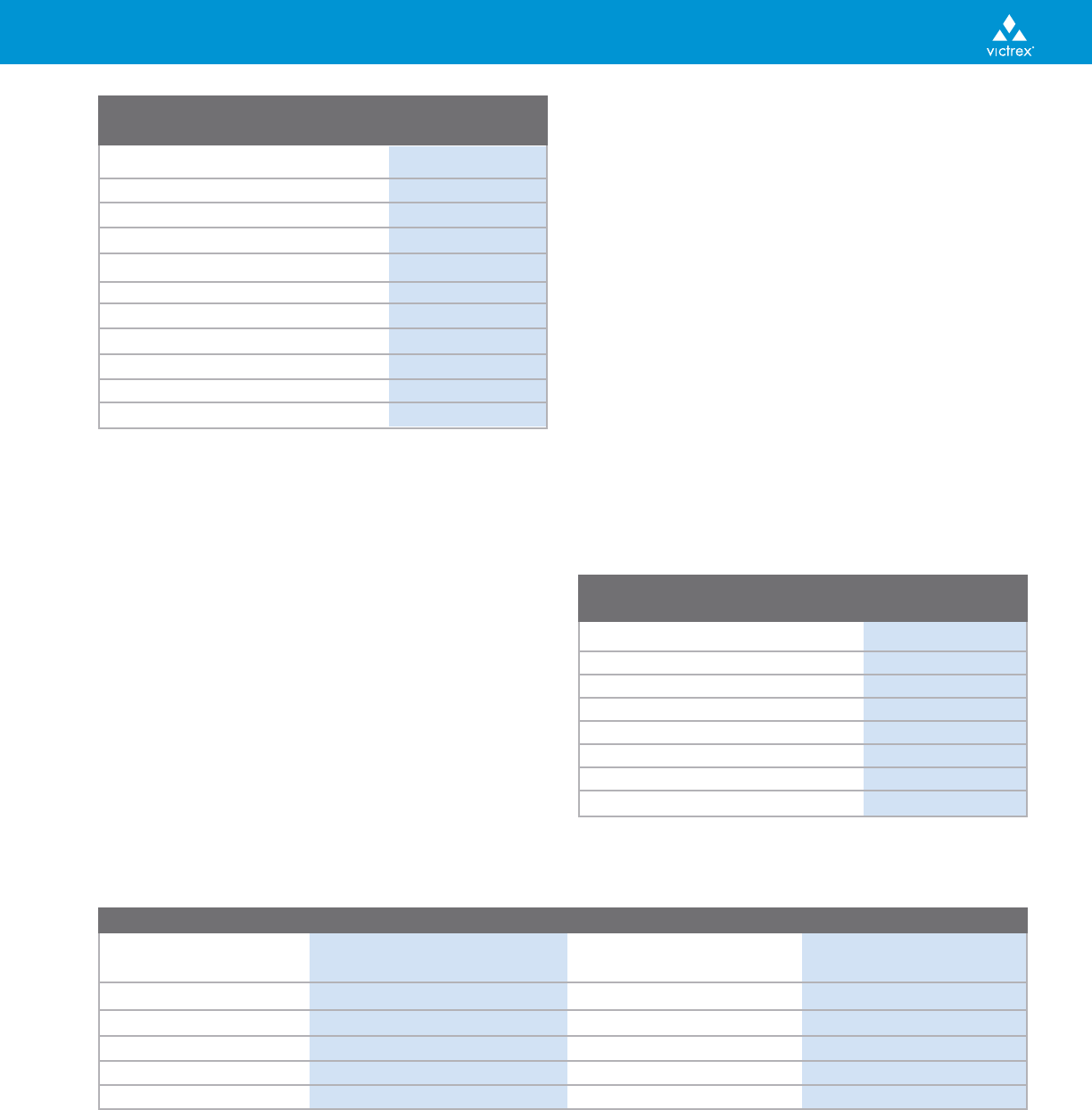

The difference between the “With Flow” and “Across

Flow” shrinkage values in Table 1 represents typical

minimum and maximum values observed in

VICTREX PEEK molding. The fan-gated plaque mold ori-

entates the melt, fibers and crystalline regions, so that a

less orientated molding should exhibit mold shrinkage

values between these two extremes. The annealed shrink-

age values in Table 1 are obtained by post process thermal

treatment in order to reach the maximum degree of crys-

tallinity. These shrinkage values may be expected in com-

ponents which are subsequently used in high temperature

environments.

Most injection molding machines have the facility for a

multi-stage injection. In order to reduce mold shrinkage

and to enhance filling, a second stage packing pressure

should be applied once the mold is full. The potential for

severe mold shrinkage may be prevented at the tool

design stage by minimizing section thickness. Molded

component tolerance may be defined as the dimensional

variation observed in seemingly identical moldings. The

tolerances shown in Table 2 were determined using the

fan-gated test plaques previously described.

% Tolerance (Molded) % Tolerance (Annealed)

Grade With Flow Across Flow With Flow Across Flow

VICTREX

450G 0.05 0.07 0.05 0.07

VICTREX

450GL30 0.07 0.08 0.03 0.05

VICTREX

450FC30 0.04 0.04 0.04 0.06

VICTREX

450CA30 0.05 0.09 0.05 0.11

* This data represents variation from the mean found in 20 samples

Table 2: Typical Tolerance Values for VICTREX PEEK*

OPERATING CONDITIONS

The optimum operating conditions for each individual

injection molding machine will depend on many vari-

ables. This section presents an overview of the practical

aspects of injection molding VICTREX PEEK based on gen-

eral experience. Table 3 shows the recommended temper-

atures required to successfully mold VICTREX PEEK.

Table 1: Typical Mold Shrinkage Values for VICTREX PEEK

170°C (338°F)

210°C (410°F)

Annealed

170°C (338°F)

210°C (410°F)

Annealed

170°C (338°F)

210°C (410°F)

Annealed

170°C (338°F)

210°C (410°F)

Annealed

170°C (338°F)

210°C (410°F)

Annealed

170°C (338°F)

210°C (410°F)

Annealed

170°C (338°F)

210°C (410°F)

Annealed

170°C (338°F)

210°C (410°F)

Annealed

170°C (338°F)

210°C (410°F)

Annealed

170°C (338°F)

210°C (410°F)

Annealed

170°C (338°F)

210°C (410°F)

Annealed

170°C (338°F)

210°C (410°F)

Annealed

170°C (338°F)

210°C (410°F)

Annealed

170°C (338°F)

210°C (410°F)

Annealed

170°C (338°F)

210°C (410°F)

Annealed

170°C (338°F)

210°C (410°F)

Annealed

3 mm

(0.118 in)

6 mm

(0.236 in)

3 mm

(0.118 in)

6 mm

(0.236 in)

3mm

(0.118 in)

6 mm

(0.236 in)

3 mm

(0.118 in)

6 mm

(0.236 in)

3 mm

(0.118 in)

6 mm

(0.236 in)

3 mm

(0.118 in)

6 mm

(0.236 in)

3 mm

(0.118 in)

6 mm

(0.236 in)

3 mm

(0.118 in)

6 mm

(0.236 in)

450G

381G

150/151G

450GL30

150GL30

450CA30

150CA30

450FC30

1.2

1.4

1.6

1.7

2.3

2.3

1.2

1.4

1.4

1.6

2.2

2.3

1.3

1.6

1.8

1.9

2.1

2.3

0.4

0.4

0.4

0.5

0.5

0.5

0.3

0.3

0.4

0.4

0.4

0.4

0.0

0.1

0.1

0.2

0.2

0.3

0.0

0.0

0.0

0.1

0.1

0.1

0.3

0.3

0.4

0.4

0.4

0.4

1.5

1.7

1.9

1.8

2.2

2.4

1.5

1.6

1.8

1.7

2.2

2.3

1.5

1.8

2.0

1.9

2.1

2.3

0.8

0.9

1.0

0.8

0.9

1.0

0.9

1.0

1.2

0.9

1.1

1.1

0.5

0.5

0.7

0.6

0.7

0.7

0.6

0.6

0.7

0.6

0.6

0.7

0.5

0.6

0.8

0.7

0.7

0.7

Mold Flow Across

Grade Thickness Temperature % Flow %

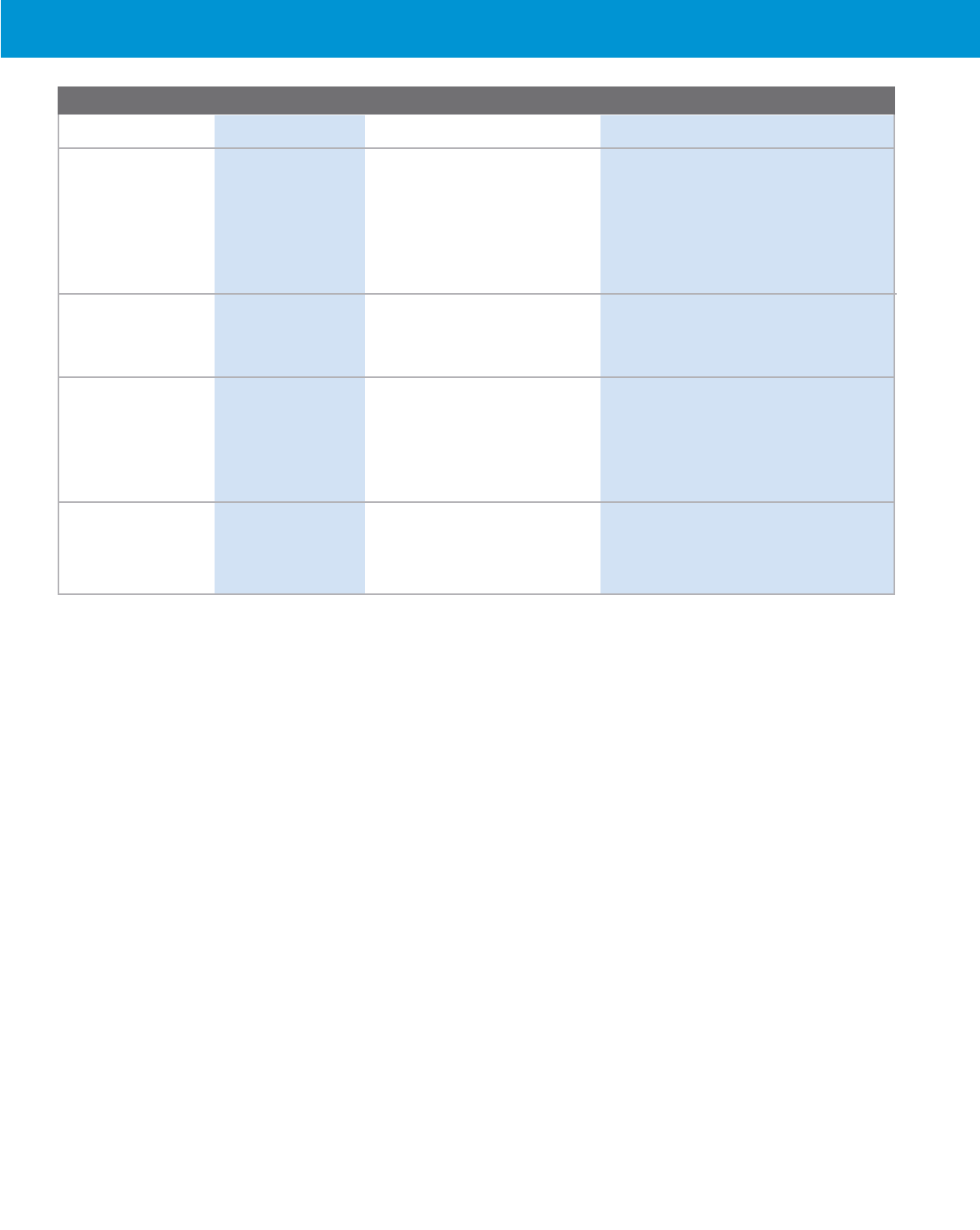

Fault Possible Cause Remedy

Dark Color and/or Low Mold Temperature Increase Mold Temperature

Transparent Edges

Short Moldings Insufficient Material Injected Increase Shot Size

Inadequate Flow of Melt Increase Injection Pressure

Increase Barrel Temperatures

Increase Mold Temperatures

Increase Injection Speed

Incorrect Design Increase Gates, Sprues or Runner Size

Improve Gates, Sprues or Runner Design

Change Position of Gate

Increase Venting

Brittle Moldings Overheating in the Barrel Reduce Barrel Temperatures

Reduce Cycle Time

Decrease Screw Speed

Molded-In Stresses Increase Barrel Temperatures

Reduce Injection Pressure

Increase Cycle Time

Increase Mold Temperatures

Increase Gates, Sprues or Runner Size

Weld Lines Increase Barrel Temperatures

Increase Injection Speed

Increase Mold Temperatures

Change Gate Design or Position

Cold Slug Material Freezing Increase Nozzle Temperature

of Polymer in the Nozzle Thermally Insulate Nozzle

Employ Decompression

Use a Sprue Break

9

Troubleshooting

Rear Temp. Middle Temp. Front Temp. Nozzle Temp.

Grade °C (°F) °C (°F) °C (°F) °C (°F)

VICTREX

150G/151G 350(662) 355(671) 360(680) 365(689)

VICTREX 381G 350(662) 360(680) 365(689) 370(698)

VICTREX 450G 355(671) 365(689) 370(698) 375(707)

VICTREX

450G Black 903 355(671) 365(689) 370(698) 375(707)

VICTREX

150GL30 355(671) 360(680) 370(698) 375(707)

VICTREX

450GL30 360(680) 365(689) 370(698) 375(707)

VICTREX

150CA30 360(680) 370(698) 380(716) 385(725)

VICTREX

450CA30 365(689) 380(716) 390(734) 395(743)

VICTREX

150FC30 355(671) 360(680) 370(698) 375(707)

VICTREX

450FC30 360(680) 365(689) 375(707) 380(716)

Table 3: Recommended Starting Temperatures

for an Injection Molding Machine Prepared for

VICTREX PEEK

INJECTION PRESSURES AND SCREW SPEED

Hydraulic injection pressures of 70 to 140 MPa (10,150

to 20,300 psi) are initially used with hydraulic holding

pressures of 40 to 100 MPa (5,800 to 14,500 psi). A nom-

inal hydraulic back pressure of up to 30 bar (435 psi) is

necessary to create an homogeneous melt and aid con-

sistency of shot size.

A screw speed of between 50 and 100 rpm is optimum

for the transport and melting of VICTREX PEEK.

However, low screw speeds (50-60 rpm) are recom-

mended for the reinforced grades to prevent excessive

fiber breakdown. Screw speeds lower than 50 rpm

should be avoided since this results in longer cycle

times. Screw speeds higher than 100 rpm are not rec-

ommended because they can cause excessive localized

shear heating.

continued

10

Fault Possible Cause Remedy

Voids and Insufficient Time or Increase Injection Pressure

Surface Sinking Pressure in Mold Increase Holding Time

Reduce Barrel Temperatures

Incorrect Mold Design Increase Gates, Sprues or Runner Size

Increase Holding Pressure

Streaking Overheated Material Reduce Barrel Temperatures

Reduce Nozzle Temperature

Reduce Residence Time

Reduce Injection Speed

Reduce Screw Speed

Damp Material Dry Material

Dead Spots in Barrel Streamline Barrel and Nozzle

Clean Screw, Barrel and Nozzle

Check for Damages, Pitting, etc.

Burn Marks Air Trapped in Cavity Reduce Injection Pressure

Reduce Injection Speed

Improve Venting of Cavity

Change Gate Position, Size or Type

Flashing or Inadequate Locking Force Reduce Injection Pressure

Mold Opening Reduce Injection Speed

Reduce Cylinder Temperature

Reduce Mold Temperature

Reduce Speed Setting

Increase Locking Force

Incorrect Mating or Re-Grind and Re-Align the Mating Surfaces

Bending of the Mold Install Heavy Backing Plates

Check for Foreign Matter Between the Plates

Warping or Temperature Difference Adjust Temperature so It Is the Same

Distortion in the Mold on Both Halves of the Mold

Lack of Section Symmetry Consider Re-Design of Cavity, Runners

and Gates

Use a Temperature Differential Between the

Two Halves of the Mold to Compensate

Use a Cooling Jig

Increase Cooling Time

Early Ejection Increase Cooling Time

Reduce Mold Temperatures

Add More Ejector Pins

Orientation of Fibers Change Gate Position

in Material Reduce Injection Speeds

Insufficient Rigidity Change Design of Components

(e.g., Add Ribs, etc.)

Increase Section Thickness

Jetting Material Entering the Cavity Reduce Injection Speed

too Quickly Change Position and/or Type of Gate

Melt too Cold Increase Melt Temperature

Excessive Processing Conditions Reduce Tool Temperature

Shrinkage Increase Injection Pressure

Increase Holding Pressure

Gate too Small Increase Gate Size

Surface Frosting Insufficient Injection Speed Increase Injection Speed

(Reinforced Grades) Increase Mold Temperatures

Increase Barrel Temperatures

Over-Shearing the Melt Decrease Screw Speed

Troubleshooting

11

EXTRUSION

Many polymer processing techniques are essentially an

extrusion operation employing specific downstream

equipment. These techniques include wire coating, pro-

file extrusion, film, sheet and monofilament production.

MACHINE DESIGN

VICTREX PEEK and compounds are readily extruded

using conventional processing technology. There are

specific requirements which are detailed below.

BARREL TEMPERATURES

Cylinder heaters must be capable of reaching 400°C

(752°F) and maintaining set temperatures to within

± 2°C (4°F). Therefore, cast aluminum heaters are not

suitable and should be replaced with either high tem-

perature alloy or ceramic heaters. Cylinder heaters

should cover all exposed metal surfaces to ensure an

even temperature distribution. Areas which cannot be

heated directly should be covered with high tempera-

ture thermal insulation to prevent the formation of

“cold spots.”

BARREL CAPACITY AND RESIDENCE TIME

The size and the output of the extruder should be

matched to obtain a short residence time, typically 5 to

10 minutes. There should be no “dead spots” i.e., gaps

around flanges or badly fitting blanking plugs. All

internal surfaces should be cleaned and polished

before extrusion commences.

SCREW DESIGN

The materials in the VICTREX PEEK grade range are

compatible with most conventional screw designs. The

only screw specifically not recommended is a continu-

ous compression “PVC” type. This screw has virtually

no feed section which results in the compacting of

polymer, leading to excessive torque. For a more

detailed overview of screw design, see Screw Design,

page 6.

WIRE AND CABLE COATING

VICTREX PEEK is widely used in the wire and cable

industry. Applications include primary insulation,

sheathing and as top coat material for wires and cables.

DIE AND CROSSHEAD DESIGN

VICTREX PEEK insulation is generally applied using a

pressure die or a “tube-on” system. Pressure dies allow

a specific thickness of coating to be metered directly

onto the conductor as it is pulled through the die.

Tube-on dies extrude the polymer outside the

crosshead and the conductor is drawn through the die

and melt. The melt is drawn and adheres to the con-

ductor, forming an insulating layer of the desired thick-

ness. The “draw-down” is expressed as a ratio of the

cross sectional area of the annulus to that of the final

coating. The recommended draw-down ratio for natur-

al VICTREX PEEK is between 3:1 and 10:1. Tube-on die

systems are more frequently used as they allow thinner

coatings of VICTREX PEEK to be applied.

The crosshead design for tube-on systems is not critical

to the process. However, the preferred design is a sin-

gle flow splitter which redirects the melt through 90°

while maintaining good stream-lined flow. Although

more complex flow splitters have proved satisfactory in

service, these systems are more difficult to clean.

WIRE AND CABLE CRYSTALLINITY

Many of the outstanding physical properties of natural

VICTREX PEEK result from its semi-crystalline morphology.

In wire and cable coating, the melt is drawn from the

die crosshead and allowed to cool in the air for approx-

imately 1 meter. While cooling, the color of natural

VICTREX PEEK changes from transparent dark brown to

an opaque grey. This change in color is due to cooling

and crystallization of the surface of the insulation.

Once this transition has taken place, additional water

cooling may be used since crystallization within the bulk

of the molten polymer will not be affected.

The temperature of the conductor may retard crystal-

lization in wire and cable coating operations.

Therefore, whenever possible, it is advisable to heat the

conductor prior to entry into the crosshead. The pre-

heat temperature will depend on the nature and

geometry of the conductor, but excellent results have

been achieved with temperatures in the 120°C to 200°C

(248°F to 392°F) range. If the desired level of crystallinity

cannot be achieved on-line, it is possible to post-crystallize

the insulation by subsequent thermal treatment.

EXTRUDER SIZE AND CONTROL

The residence time of the polymer in the process equip-

ment influences the quality of the final insulation. The

thermal stability of VICTREX PEEK is exceptional, but

gel formation can occur during processing and manifest

itself as a gritty surface on the insulation. The screen

packs disperse these gels very effectively in the melt,

but any gels created downstream will be present in the

extrudate. Therefore, the capacity and throughput of

the extruder should be matched.

12

SHEET MANUFACTURE

Natural VICTREX PEEK may be used to form sheets. The

processing is carried out using a conventional extruder

with suitable die and haul-off equipment, as depicted in

Figure 7.

A general guide to the processing conditions required

to successfully form sheets from VICTREX PEEK is given

in Table 4.

DIE DESIGN

Slot dies are recommended for processing natural

VICTREX PEEK into sheets. These systems should have a

streamlined melt flow with polished interiors to pre-

vent hold-up or die stick-slip. The temperature of the

die lip is crucial for good surface finish and dimensional

control. Die lips should be maintained at 380°C (716°F)

± 2°C (4°F).

THIN FILM AND SHEET CRYSTALLINITY

Thin sheet [500 µ (< 0.02 in)] may be produced in either

semi-crystalline or amorphous form by controlling the

temperature of the casting drums. A drum temperature

of 50°C (122°F) will produce an amorphous transparent

film, while a 170°C (338°F) temperature will give

opaque semi-crystalline film. As the thickness of the film

increases [500 µ (< 0.02 in)], it becomes more difficult to

control the degree of crystallinity. If necessary, the level

of crystallinity within films can be optimized through

post process thermal treatment.

MONOFILAMENT

VICTREX PEEK may be processed to form monofilament

using an extruder with downstream haul-off and draw

facilities. Extruders used for the production of monofil-

ament are generally fitted with gear pumps. These

ensure that an accurately metered supply of melt is fed

to the die at constant pressure. Other non-metered sys-

tems have proved satisfactory in service. A typical

monofilament production line is depicted in Figure 8.

The post-extruder processing depicted in Figure 8 can

be considered in two distinct parts: melt orientation

and relaxation. During melt orientation the extrudate is

air and water cooled at a haul-off velocity of V

1

. The

filament is drawn at a velocity V

2

through an oven

which is set above the glass transition of the material.

The difference in velocities V

1

and V

2

serves to draw

the polymer, reducing the diameter and orienting the

filament.

During melt relaxation, the polymer is “heat set” by

passing through a second oven (velocity V

3

) which is

close to the melt temperature of the material. The dif-

ference in velocities V

2

and V

3

serves to relax the poly-

mer, increasing the diameter of the monofilament.

Typical values of temperature and velocity for the pro-

duction of a 0.4 mm (0.016 in) diameter monofilament

from a 40 mm (1.57 in) diameter single screw extruder

are given in Table 5.

S

Water Quench

Temperature

T

1

V

1

Drawing Oven Heat Setting Oven

Figure 8: A Schematic Representation of Monofilament

Production Equipment

T

2

V

2

V

3

T

3

Figure 7: Sheet Producing Equipment

Screw 32 mm (1.26 in) Diameter Screw

Die 300 mm (11.81 in) Slot die

Screw Speed 40 rpm

Filters 2 layers of 400# woven stainless steel

mesh plus supporting mesh fitted into

the breaker plate

Rear Middle Front

Cylinder

Temperatures 340°C (644°F) 375°C (707°F) 375°C (707°F)

Die Lips 380°C (716°F)

Die Temperatures 380°C (716°F)

Table 4: Typical Conditions for Extruding Sheets

Using VICTREX PEEK

Slot

Die

Three

Roll

Stack

Extruder

Melt Temperature 375°C (707°F)

Filter Pack 3 x 200#

Die to Water Surface Distance (S) 700 mm (27.5 in)

Water Quench Temperature T

1

60°C (140°F)

Draw Down Ratio V

2

:V

1

3.5 : 1

Drawing Oven Temperature T

2

200°C (392°F)

Heat Setting Oven Temperature T

3

280°C (536°F)

Draw Relaxation V

3

:V

2

0.95 : 1

Output 3.1 kg h

-1

(6.8 lb h

-1

)

Die (16 Hole) 1.12 mm (0.044 in)

Monofilament Diameter 0.4 mm (0.016 in)

Table 5: Typical Monofilament Production Conditions

for a Single Screw Extruder

Energy to Break 1.24 J (0.91 ft lbs)

Tensile Load at 2% Elongation 1.18 kg (2.6 lbs)

Tensile Load at 5% Elongation 1.77 kg (3.9 lbs)

Tensile Load at 10% Elongation 2.66 kg (5.86 lbs)

Tensile Load at Break 5.81 kg (12.8 lbs)

Elongation to Break 22.0%

Knot Strength 2.42 kg (5.34 lbs)

Shrinkage in Air at 200°C (392°F) 3.5%

Table 6: Properties of a 0.5 mm (0.02 in) Monofilament

Prepared as Specified in Table 5

Test Tensile Stress (yield) Tensile Stress (break) Modulus

Temperature MPa (psi) MPa (psi) GPa (psi)

23°C (73°F) 110 (16,000) 325 (47,100) 6.9 (1,000,000)

100°C (212°F) 70 (10,200) 280 (40,600) 5.7 (827,000)

150°C (302°F) 45 (6,500) 250 (36,300) 5.3 (769,000)

250°C (482°F) 20 (2,900) 120 (17,400) 0.9 (131,000)

300°C (572°F) 6 (870) 90 (13,100) 0.25 (36,300)

Table 7: Retention of Monofilament Properties at Elevated Temperatures

13

MONOFILAMENT ORIENTATION

The physical properties of natural VICTREX PEEK can be

modified by solid state orientation. If the filament is to

be oriented in a second stage process, it must be

quenched upon leaving the die so that it becomes

amorphous. However, care must be taken not to cool

the filament too rapidly or voids will form. Air cooling

followed by immersion in a water bath or direct immer-

sion into a heated water bath have both proven suc-

cessful in service. The optimum distance from the die to

the water bath and the temperature of the water

depend on the thickness of the filament. However, a

small diameter [0.25 mm (0.01 in)] filament would typi-

cally require a 100 to 200 mm (4 to 8 in) air cooling fol-

lowed by a water quench at 20°C to 50°C (68°F to

122°F). If the monofilament temperature is too high,

then the water in the bath will boil locally causing mar-

ring on the polymer surface.

VICTREX PEEK will be oriented using either a single stage

(Figure 8) or a two stage draw where the filament is

necked at 120°C (248°F) and then drawn at 200°C (392°F).

The properties which develop in the drawn filament will

be dependent on the level of draw-down. Draw-down

ratios between 2.5:1 and 3:1 are recommended. Above

3:1, the knot strength of the filament decreases rapidly.

The maximum sustainable draw-down that has been

achieved using VICTREX PEEK is 3.8:1.

When orientation is developed in the monofilament, it

is necessary to heat set it under tension. Heat setting is

usually carried out at a temperature approaching the

melting point of the polymer (typically 6 seconds at

280°C (536°F) under a draw relaxation of 0.95:1). The

resultant monofilament is tough, highly oriented, and

has a controlled diameter which will retain its set form

above the glass transition temperature of the material.

Typical physical properties of such monofilaments are

shown in Tables 6 and 7.

14

COMPRESSION MOLDING

The following information is only a guide to produce

compression molded parts based on historical informa-

tion and data generated over several years. Processors

may well have to modify their conditions i.e. pressures

and temperatures according to the parts being produced.

BASIC PROCESS

The polymer, which will be generally VICTREX 450PF

(bulk density <0.6 g cm

-3

) grade fine powder needs to

be pre-dried for 3 hours at 150°C (302°F) or overnight

at 120°C (248°F), to try and avoid the problems of

porosity/bubbles. Normal VICTREX PEEK powder or

pellets can be compression molded but granular bound-

ary marks will always be evident and will be a weak

point in the molding. Drying the polymer in the mold

itself is acceptable but drying times may need to be

adjusted depending on the depth of material. The

mold tools themselves should be pre-dried at around

150°C (302°F) before use. A small amount (2-3%) of

PTFE lubricant grade powder compounded into the

VICTREX PEEK may aid part ejection.

The dried polymer with ~ 102% of the theoretical

weight of polymer required to form the component is

compacted in the mold with a pressure of between 350

to 700 bar (5000 and 10,000 psi) to enable the trapped

air in the mold to escape before the mold is heated up.

The heating of the mold can be accomplished by

preferably internal and external heater bands or if

heater bands are not available an air-circulating oven

can be used. Prior to heating the mold, the pressure

should be “backed off” to 140 bar (2000 psi).

The temperature of the mold is raised to 390 - 400°C

(734 - 752°F) as fast as the heaters will allow until the

polymer is fully molten. The pressure should be held for

15 minutes for every 25 mm (1 in) section thickness.

Some flashing may occur but this is normal.

The molding is then cooled down at a rate of approxi-

mately 40°C (72°F) per hour while still under pressure

until the part has reached <150°C (302°F) when the

part can be ejected. The use of thermocouples should

be used to monitor cooling rate.

EQUIPMENT REQUIREMENTS

Press: Should be capable of delivering sufficient pres-

sure. Typically up to 700 bar (10,000 psi).

Molds: Should be corrosion resistant metals. Good

results have been obtained with Stavax, Duplex

(Ni/Chromium) and hard chrome plated stainless steel,

also P20 hard tool steel with a Rockwell hardness of 50

has been used with success. Mild steel and steels con-

taining copper should not be used. Mold surfaces in the

line of draw should be polished to aid ejection.

A mold release agent is recommended such as one of

the Frekote products (without silicon) to aid ejection.

Clearance between sliding parts should be between

0.075 and 0.125 mm (0.003 and 0.005 in). PTFE, alu-

minum, steel (20-30 Rockwell) sealing rings have been

used with effect between the punch plate and the

molten polymer.

Internal and external heater bands are preferable but a

hot air circulating oven capable of achieving at least

400°C (752°F) can be used. Care should be taken to

avoid thermal degradation of the polymer.

COMPRESSION MOLDING CHARACTERISTICS

Properties of compression molded VICTREX PEEK parts

differ from injection molded parts. As a general rule

the compression molded parts are more crystalline,

have a higher modulus and tensile strength, are harder

but have a lower ductility and can be more brittle.

Milled fibers (glass and carbon) may be compounded into

VICTREX PEEK for compression molding albeit with loss of

anisotropy, lower strength, different C.T.E. and different

tribological properties than injection molded parts.

Very thick sections may be subject to cracking and a post

processing thermal treatment (annealing) should be used

to relieve stresses. See Victrex literature on annealing.

Close tolerances cannot be achieved directly therefore

components must be machined. See Victrex literature

on machining. The outer and inner surfaces of mold-

ings may be discolored due to the mold release agent

and being in contact with the tooling, these surfaces

should be skimmed to remove the discoloration.

POWDER COATING

VICTREX PEEK in fine powder form may be used to coat

metal substrates. Thick coats of up to 2 mm (0.078 in)

can be applied by electrostatic spraying or fluidized

bed coating. Coatings as thin as 25 µ (0.001 in) may be

obtained using dispersion techniques.

Regardless of whether a part is coated by the electro-

static or dispersion process, the appearance of the coat-

ing can be modified via the last heat cycle. Three sur-

face finishes are possible; standard crystalline (air

cooled), amorphous (quenched in cold water*) or gloss

(quenched in cold water and subsequently annealed to

achieve a gloss finish).

* Parts that are quenched can generate steam and localized boiling water.

15

ELECTROSTATIC SPRAY AND FLUIDIZED BED

COATING

Electrostatic spray and fluidized bed coating are both

methods of transporting solid VICTREX PEEK powder

onto the heated surface of the metal substrate. Once

the fine powder comes into contact with the metal, the

particles adhere to the surface and eventually form a

cohesive layer.

Electrostatic spray techniques generally involve the air

transportation of fine powder to the nozzle of an elec-

trostatic spray gun. A large potential difference is

applied between the nozzle and the substrate, which

serves to direct the jet of fine powder. Fluidized bed

techniques use pressurized gases to circulate a given

mass of fine powder material in a fixed volume. A con-

trolled cloud of powder is created into which the heat-

ed substrate may be lowered.

Before coating, substrates should be prepared by grit

blasting and degreasing in appropriate solvents. This

will remove contamination and properly prepare the

surface of the metal for polymer adhesion. The metal

substrate should be heated to between 400°C and

420°C (752°F and 788°F) and the fine powder coating

applied. Oxidation will reduce the surface energy of

the metal and lead to poor adhesion. Therefore, freshly

prepared surfaces are recommended for the best

results and exposure of the heated metal to oxygen

should be minimized or avoided, if possible.

After the final coating the part should be placed into

the oven for final “flow-out” of the VICTREX PEEK

coating and then removed from the oven and allowed

to cool. The degree of crystallinity within the coating

may be controlled by the cooling regime imposed.

Amorphous layers are frequently post conditioned to

reach the optimum level of crystallinity by placing the

component in an air circulating oven at 200°C (392°F)

for 30 minutes.

When coating components with a large thermal mass,

slower cooling rates will cause the development of

high levels of crystallinity which may cause cracking of

the coating. Levels of crystallinity can be controlled by

ensuring that the coating is cooled at an appropriate

rate, for example, by the use of a cool air flow. Water

quenching may lead to thermal shock and is not recom-

mended.

DISPERSION SPRAY COATING

VICTREX PEEK-based coatings in a range of 25 to 100 µ

(0.001 to 0.004 in) thickness can be applied using dis-

persions of VICTREX PEEK fine powder in an aqueous

medium. Dispersions can be used to coat stainless and

carbon steels, aluminum, castings and ceramics. Since

they are based on high-flow VICTREX PEEK, dispersions

are ideal for coating complex geometries and provide

superior coverage around holes, deep draws and recesses.

Like other types of VICTREX PEEK-based coatings, dis-

persion coatings have very low wear and friction prop-

erties, superior chemical and steam resistance, excellent

mechanical properties (hardness, creep resistance, etc.)

as well as low extractable content and good purity.

FINISHING OPERATIONS

Components made from VICTREX PEEK and compounds

may be used in a number of finishing operations such

as machining, bonding, coloring or metallization.

MACHINING

Often, for prototype designs or short production runs,

it is not economically viable to manufacture an injec-

tion molding tool. Under such circumstances, it is com-

mon to machine VICTREX PEEK materials to form com-

ponents. VICTREX PEEK may be machined and finished

using the same techniques and equipment as for other

engineering thermoplastics. However, due to the excel-

lent physical properties and wear characteristics of

these materials, it is necessary to use carbide or dia-

mond tipped tools and bits.

Machining and finishing operations on polymeric materi-

als can release molded-in or residual stresses. Before

machining, components formed from VICTREX PEEK

should be annealed to relieve stress. An annealing proto-

col is detailed in the section on Annealing. During

machining or finishing, further stresses may be built-up

within the material by localized heating at the cutting

point. Therefore, if a large amount of machining and

finishing is to be carried out on a component, a second

annealing procedure prior to finishing is recommended.

The thermal conductivity of all polymeric materials is

lower than that of metals, so heat build-up during

machining is rapid. A cooling fluid should be used to

remove some of the heat generated by working the mate-

rial. Water is generally recommended for use with all the

VICTREX PEEK based materials. A summary of the suggest-

ed machining guidelines is shown in Table 8 (page 16) .

PROTOTYPE PERFORMANCE

Prototype components are generally the best way to

evaluate the performance of a material under a certain

set of application-specific conditions. However, the

physical performance of a machined component will

differ slightly from that of a seemingly identical injec-

tion-molded component. This phenomenon may be

explained in terms of the inherent physical conse-

quences of a molding procedure, including the produc-

tion of skin/core effects and fibre orientation.

16

ANNEALING

Components formed from VICTREX PEEK can be

annealed to increase levels of crystallinity, remove any

thermal history, limit subsequent dimensional changes

at high temperatures, or to remove stresses. The appro-

priate annealing procedure will depend on the objec-

tive of the process.

AN OVERVIEW OF ANNEALING FOR

OPTIMUM CRYSTALLINITY

Increasing crystallinity within a component may be nec-

essary if a brown amorphous skin is observed (this can

also be eliminated by increasing mold temperature), or

enhanced strength and chemical resistance is required.

(a) Dry the component for a minimum of three hours at

150°C (302°F).

(b) Allow the component to heat up at 10°C (18°F) per

hour until an equilibrium temperature of 200°C

(392°F) is reached.

(c) The holding time for components is dependent on

section thickness. It is recommended that annealing

temperatures are held for at least 4 hours.

(d) Allow the component to cool at 10°C (18°F) per

hour until the system falls below 140°C (284°F).

(e) Switch off the oven and allow the component to

cool down to room temperature.

Annealing temperatures close to 300°C (572°F) have

been used to maximize mechanical performance

(strength and modulus) and chemical resistance.

However, these effects may be accompanied by embrit-

tlement and surface oxidation because of the high

annealing temperature.

AN OVERVIEW OF ANNEALING TO REMOVE

STRESSES

Injection molding or machining operations may add

stresses to a component. These stresses reduce the

physical performance of devices and may be removed

by annealing the sample as described above, with a

holding temperature up to 250°C (482°F).

AN OVERVIEW OF ANNEALING TO REMOVE

THERMAL HISTORY AND SHRINKAGE

Dimensional stability over a wide temperature range

may be crucial to some applications. Components may

be annealed to remove distortion effects or thermal

history.

(a) Dry the component for a minimum of three hours

at 150°C (302°F).

(b) Allow the component to heat up at 10°C (18°F) per

hour until an equilibrium temperature which

exceeds the normal service temperature is reached.

(c) The holding time for components is dependent on

section thickness. It is generally recommended that

temperatures are maintained for at least 4 hours.

(d) Allow the component to cool at 10°C (18°F) per

hour until the system falls below 140°C (284°F).

(e) Switch off the oven and allow the component to

cool down to room temperature.

Units VICTREX PEEK Reinforced VICTREX PEEK Compounds

TURNING

Cutting Speed m min

-1

(ft min

-1

) 300 (984) 120-180 (394-590)

Feed mm rev

-1

(in rev

-1

)0.4 (0.016) 0.2 (0.008)

Relief Angle ° 5 5

Top Rake Angle ° 6-12 6 - 12

Cutting Depth mm (in) 6.5 (0.25) 7.5 (0.29)

Coolant None None

MILLING

Cutters - Standard or Carbide Tip Carbide Tip or Diamond Tip

Cutter Speed m min

-1

(ft min

-1

) 590-754 (180-230) 78-110 (256-361)

Coolant - Water/Oils Water/Oils

DRILLING

Cutting Speed m min

-1

(ft min

-1

) 120 (394) 75-120 (246-394)

Feed mm rev

-1

(in rev

-1

) 0.05-0.20 (0.002-0.008) 0.05-0.20 (0.002-0.008)

Lip Angle ° 118 118

Clearance Angle ° 12 12

Coolant - Water/Oils Water/Oils

REAMING

Runners - Spiral Flute Spiral Flute

Speed rev min

-1

100-200 100-200

Coolant - Water/Oils Water/Oils

Table 8: Guidelines for the Machining and Finishing of VICTREX PEEK

17

IF - adhesive failure at the adhesive / substrate interface

CF - cohesive failure of the adhesive, leaving adhesive on both sides of the substrate

SF - the adhesive is of sufficient strength to cause failure within the VICTREX PEEK substrate

ICF - mixed mode failure with fracture propagation switching between interfacial and cohesive failure

ADHESIVE BONDING

VICTREX PEEK and compounds may be bonded using a

variety of common adhesives. For specific adhesive

applications please contact Victrex for recommendation.

ADHESIVE TYPES

Most adhesive types are compatible with the VICTREX

PEEK-based materials. Epoxy, cyanoacrylate, anaerobic

and silicone adhesives have been shown to successfully

bond VICTREX PEEK. A list of typical adhesives and

their corresponding bond strengths is shown in Table 9.

From the data shown in Table 9 it is clear that some of

the epoxy systems tested give superior bond strengths

to other conventional adhesives.

SURFACE PREPARATION

Surfaces which are to be joined by an adhesive bond

should be clean, dry and free from grease and other

contamination.

There are a variety of surface treatments available

which increase the strength of adhesive bonds made

with VICTREX PEEK. A comparison of bond strengths

achieved using the most common of these techniques is

made in Table 10. For these measurements VICTREX

450G samples were bonded together in a single over-

lap shear geometry with a two-component epoxy from

Ciba (AV138M/HV998) and using a 15 minute 100°C

(212°F) curing cycle.

WELDING

VICTREX PEEK may be bonded using conventional ther-

moplastic welding techniques. However, these materi-

als have exceptionally high melt temperatures, and

considerable amounts of energy must be put into the

interface to achieve a good bond. Satisfactory results

have been obtained using hot plate, friction and near-

field ultrasonic welding.

Bond Strength/MPa (psi)

Untreated 0.7 (102)

Roughening 2.1 (305)

Acid Etch 5.5 (798)

Excimer Laser 5.6 (812)

UV Lamp 5.0 (730)

Plasma Chamber 5.0 (722)

Table 10: Comparison of Surface Preparation Techniques

for Adhesive Bonds to VICTREX 450G

VACUUM METALLIZATION

VICTREX PEEK materials may be used as substrates in a

thermoplastic metallization process. Care should be

taken when injection molding or machining such com-

ponents to ensure a good surface finish. A poor finish

will result in a non-uniform coating. Substrates must be

clean, dry and free of contamination before the appli-

cation of the metal coating.

COLORING VICTREX PEEK

VICTREX PEEK is available in a natural grey color or as a

black material. The color is modified by its constituents,

i.e., carbon reinforced materials are black in color while

glass fiber reinforced materials are a light grey.

VICTREX PEEK may be colored using a masterbatch

additive.

Failure Stress / MPa (psi)

Adhesive Type Manufacturer 23°C 120°C 150°C 200°C

S-4215 RA Acrylic tape ATP Adhesive Systems 0.2 (29) CF 0.03 (4.3) CF - -

Araldite AV138M + HV 998 Epoxy Huntsman 5.5 (800) IF + CF 3.4 (500) CF - -

Araldite AV 119 Epoxy Huntsman 41.8 (6000) SF 4 (575) CF 1.5 (225) IF + CF -

HAF 8401 Nitrile rubber Tesa AG 47.3 (6850) SF 2.4 350) IF 1.9 (275) IF -

phenolic resin

Duralco 4460 Epoxy Cotronics Corp. 1.7 (250) ICF - 0.5 (75) CF 0.4 (58) IF +CF

Duralco 4703 Epoxy Cotronics Corp. 16.7 (2400) SF - 3.4 (500) CF 1 (145) CF

EPO-TEK 353 ND Epoxy Epoxy Technology 36.2 (5250) SF - 3.1 (450) CF 1 (145) IF + CF

Duralco 4525 Epoxy Cotronics Corp. 3.3 (475) CF - - 0.6 (87) CF

Table 9: Bond Strength of Various Adhesives with VICTREX PEEK-Based Materials

18

POLYMER SPECIFICATIONS AND APPROVALS

VICTREX PEEK and compounds are recognized or approved by the following bodies:

AEROSPACE/MILITARY

FAR 25-853 VICTREX 381G, 450G, 450GL30 and 450CA30 meet the fire, smoke and toxicity standard

FAR 25-853 for aircraft cockpit use.

ATS 1000.001 VICTREX 381G and 450G meet the fire, smoke and toxicity standard ATS 100.001 for optical

density and toxicity of fumes from burning.

SP-R-0022A VICTREX 450G meets the NASA standard SP-R-0022A for vacuum stability of polymeric

materials in spacecraft applications.

BMS 8-317A VICTREX PEEK unfilled glass and carbon filled polymers can be supplied to Boeing specification

BMS 8-317A for use in aircraft applications.

MIL-P-46183 VICTREX PEEK and compounds can be supplied to the military specification MIL-P-46183.

Staining Test VICTREX 381G complies with the Boeing Aircraft staining test.

#DMSRR 1018 VICTREX CA30 complies with the Rolls Royce standard #DMSRR 1018.

75-T-2-3007-4-1 VICTREX CA30 meets the Deutsche Aerospace/Airbus standard 75-T-2-3007-4-1.

MS29.02.03 VICTREX 450GL30 can be supplied to Sundstrand Aerospace materials specification MS29.02.03

JAR 25.853 VICTREX 381G meets the fire, smoke and toxicity standard JAR 25.853 for flame resistance.

S26 4625 VICTREX 381G meets the fire, smoke and toxicity standard S26 4625 for non-flaming smoke

generation.